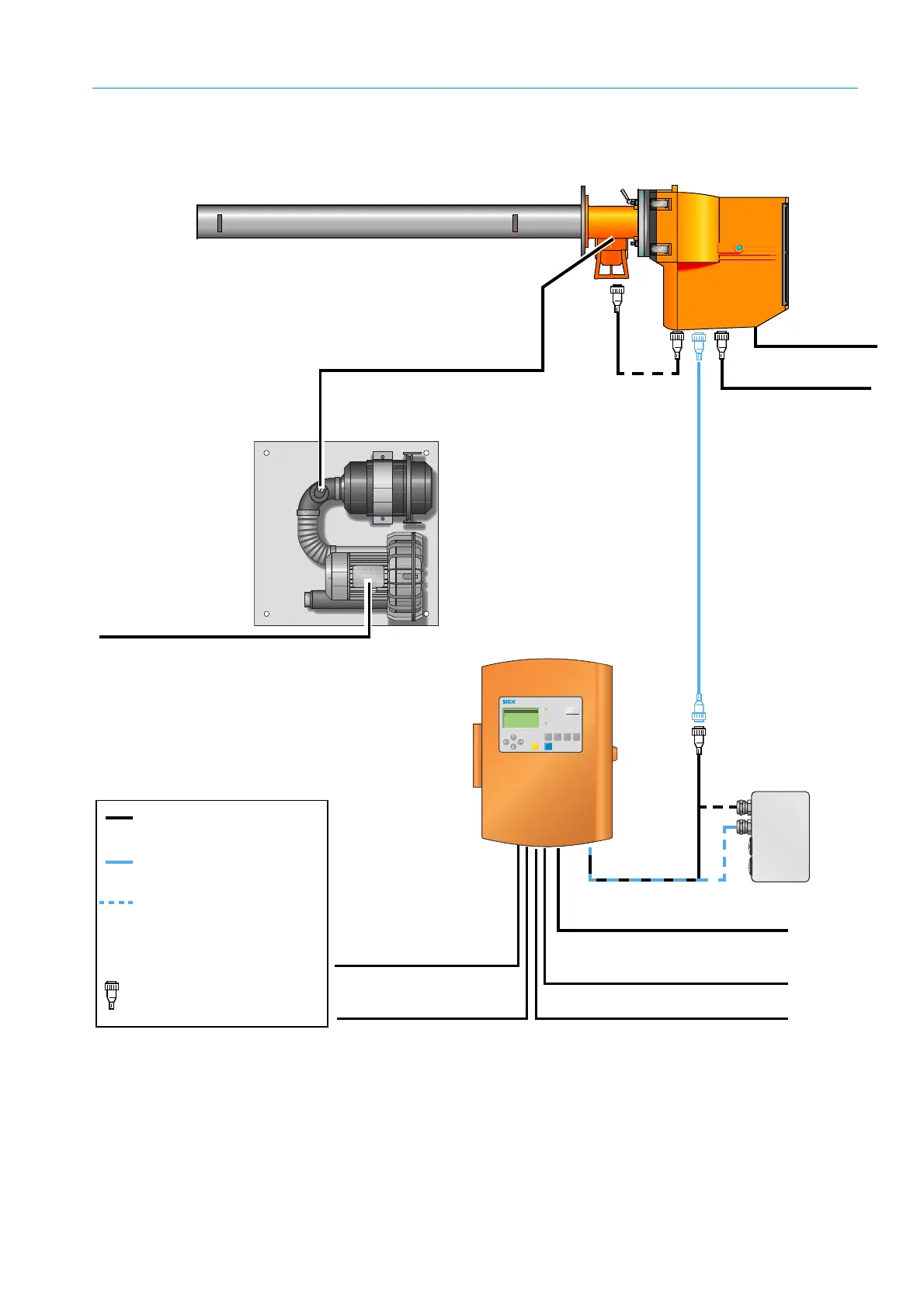

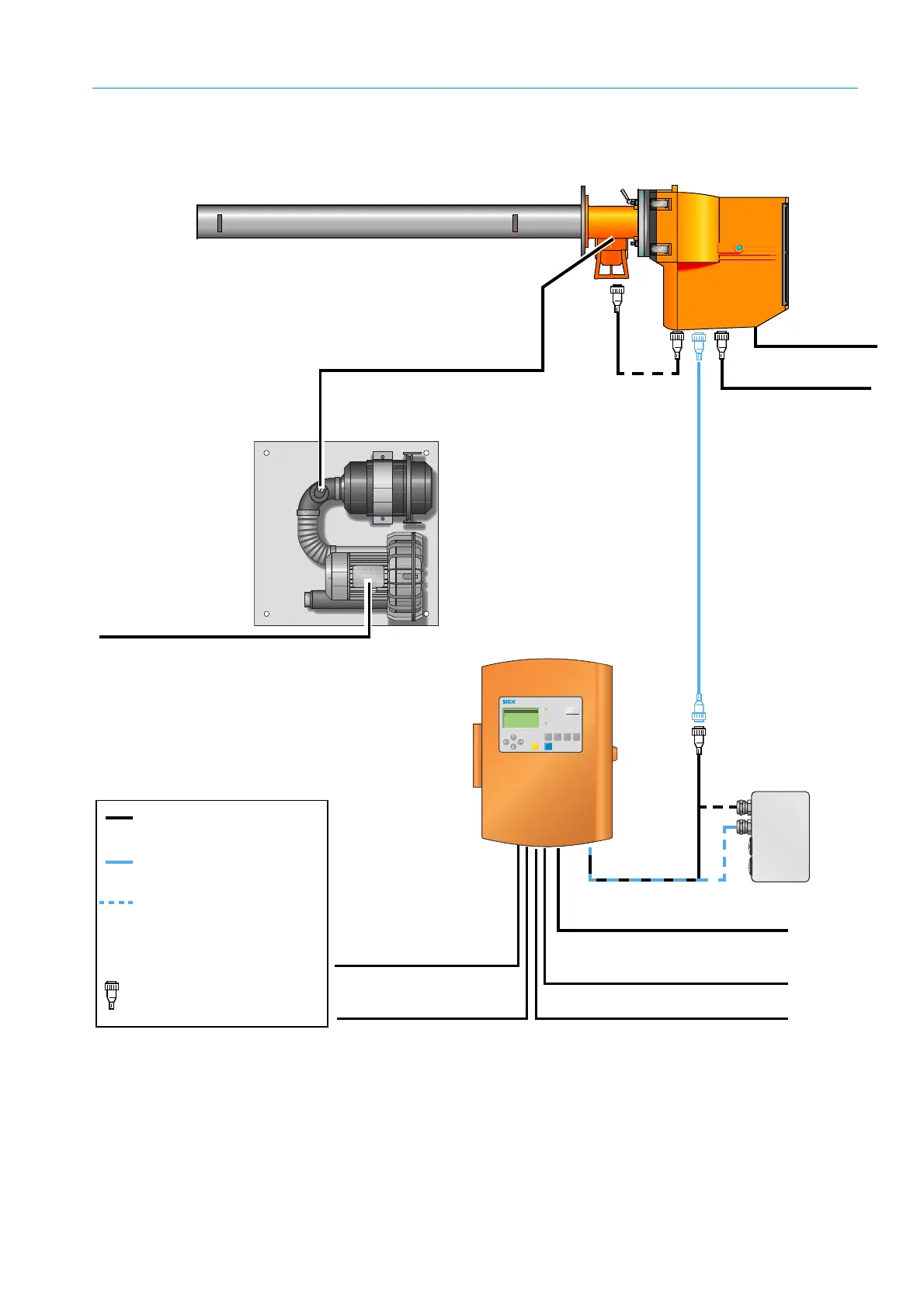

Fig. 11: Cable routing diagram

Power supply

(230/115 V AC) *

4m, 3 x 1.5mm

2

SR-unit

Measuring probe (example: GMP)

CAN *

1m

Evaluation unit

CAN bus extension, ready

for connection, 15 m

CAN bus cable (stan-

dard), 4 m *

Terminal box (option)

Standard cable

connection

Cable connection,

option

Cable in scope of

delivery

*

Prefabricated with plug-in

connector(s)

Purge air unit SLV4

(Standard for GMP

measuring probe)

Power supply 4 x

1.5 mm

2

Signal cable for:

• Filter monitoring of the SLV 4 – 2 x 0.6 mm

2

,

on pressure controller with flat pin bushings

6.3 x 0.8 mm (DIN 46247)

• Pressure connection

Functional

earth 2.5 mm

2

Power supply (230/115 V AC)

3 x 0.75 mm

2

3 binary inputs 6 x 0.5 mm

2

3 analog inputs 6 x 0.5 mm

2

3 binary outputs 6 x 0.5 mm

2

3 analog outputs 6 x 0.5 mm

2

to lengthen the CAN bus

connection with a cable

(1 x 2x 0.5mm

2

, twisted

pair, shielded) provided by

the customer

Cable connection for

optional terminal box

Loading...

Loading...