21

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

PRODUCT OVERVIEW

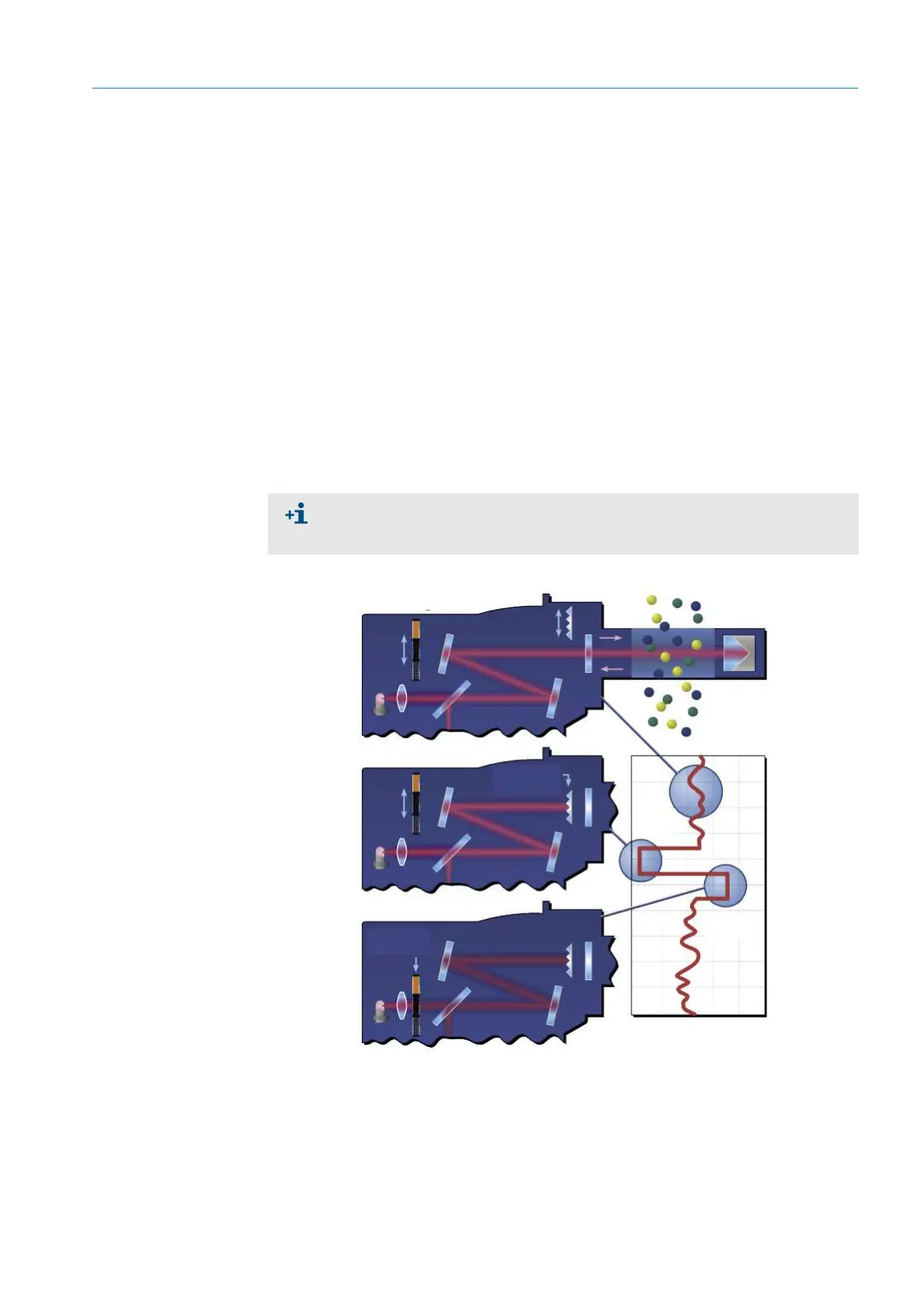

2.2.3 Automatic check cycles

To ensure a consistently high level of measuring precision, the GM35 SR-unit performs a

regular automatic check cycle in an adjustable interval (standard: Every 2 hours). In this

check cycle, the zero point is first determined by swiveling a zero point reflector into the

beam path. Reference filters are then moved into position to control the check point. The

spectral properties of the device are checked using a test gas cell. If a check cycle reveals

that the system is not functioning in accordance with the operation specifications, the

GM35 measuring system outputs appropriate error or warning messages.

Triggering options

1 Di 1 (falling edge): The check cycle can also be suppressed with this function.

2 Time interval, adjustable via the menu of the EvU.

Sequence

1 Check cycle is started.

2 Internal reference measurement is executed. Signal: Relay 3 (function check)

3 The zero point and check point are output on the EvU display and the assigned analog

outputs for 90 seconds each. Relay 3 remains active.

Fig. 7: Determining the check point

Observe the following for connecting to an emission computer: Measure the

time from the start to the output to compensate differences in the device

settings.

Measure

Zero point

Check

Zero point

Check point

(70% fsc)

Zero point reflector

Swivel element

Data recorder

Loading...

Loading...