60

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

CONNECTING THE SYSTEM CONTROL UNIT - SCU

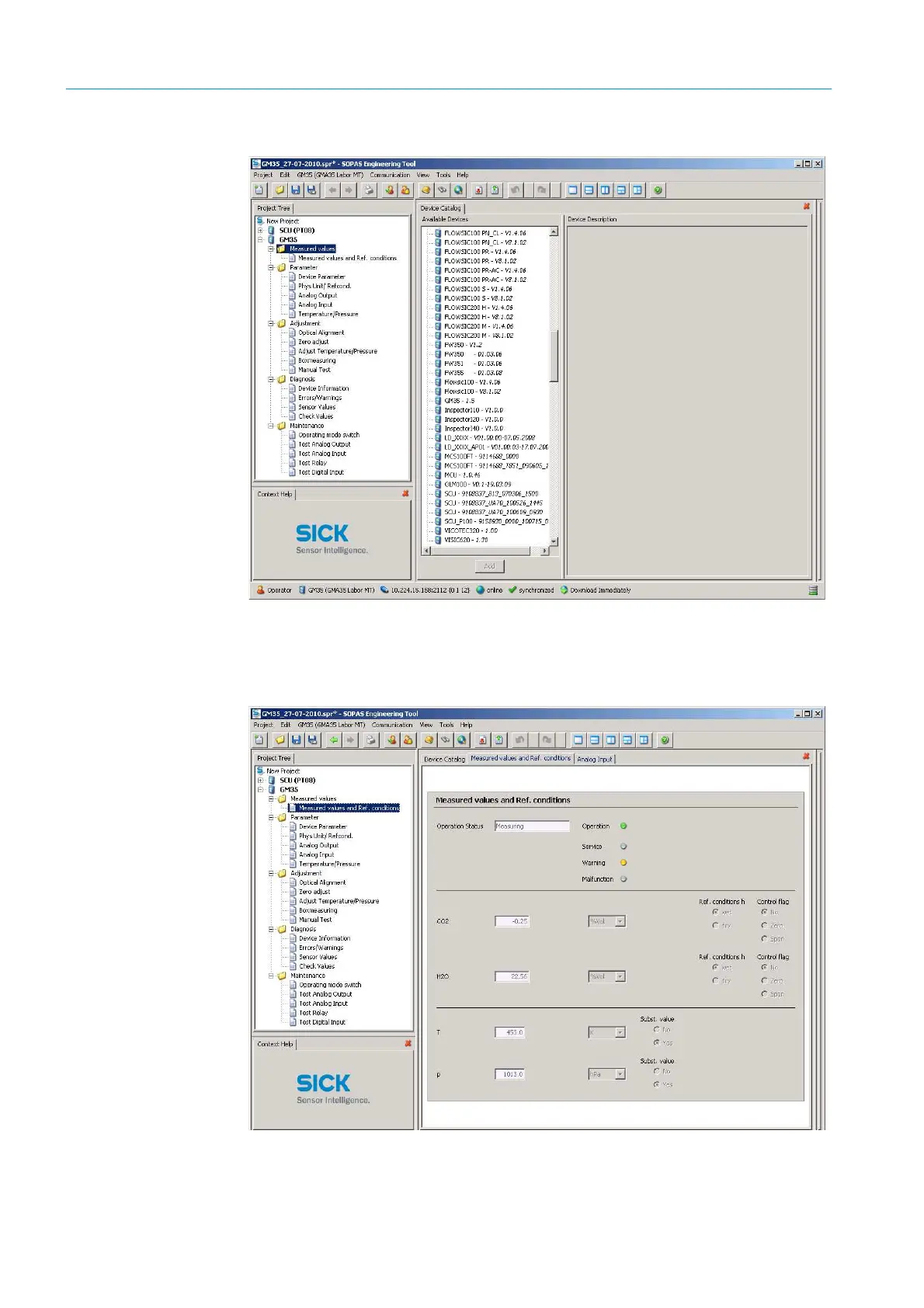

6.1.6 Menu overview (menu tree)

Fig. 27: GM35 menu tree

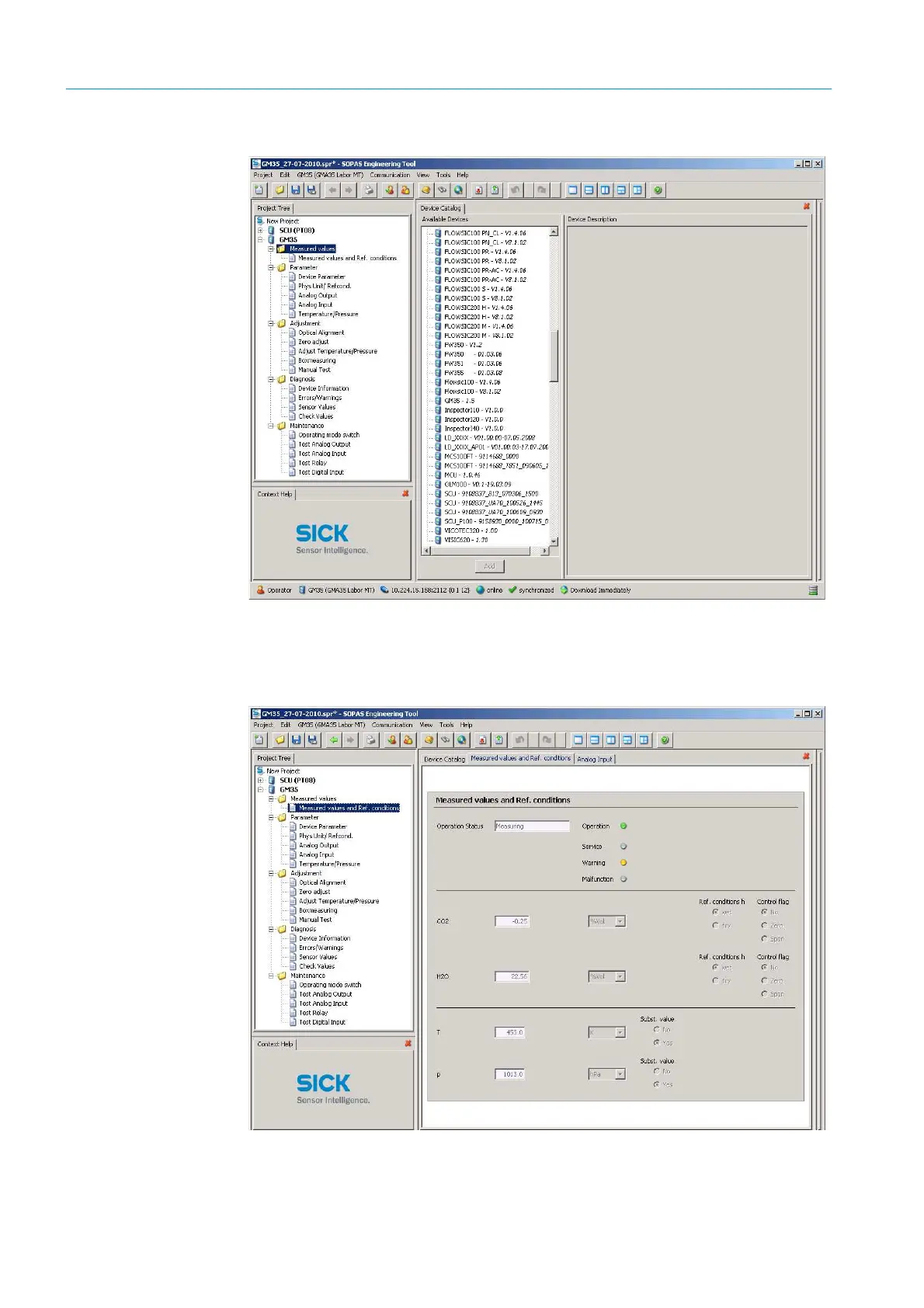

6.1.7 Measured values

Menu GM35/Measured values

Fig. 28: Menu: Measured values and Ref. conditions

Loading...

Loading...