29

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

PROJECT PLANNING INFORMATION

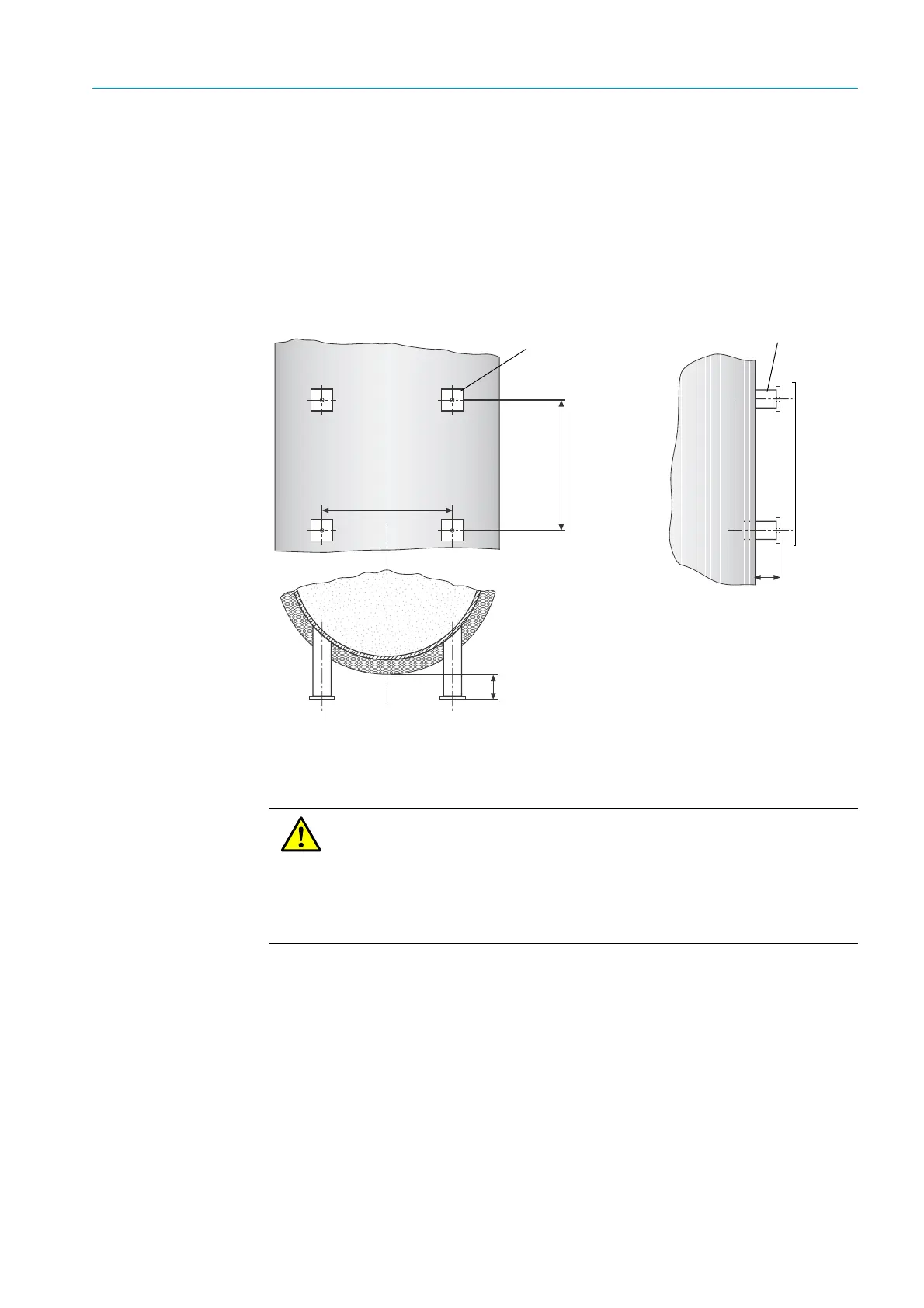

3.3.4 Installation preparation for the purge air unit

Is a purge air unit to

be used?

This step is only relevant for device configurations containing a purge air unit. GM35

configurations with GPP measuring probes do not require purge air.

1 Make brackets from steel pipes (e.g. 50 x 5) with flanges (e.g. FL 60 x 8 x 60) for the

four fixing points of the purge air unit ; bore M10 threads in the mounting holes.

2 Weld the brackets on as shown when using steel ducts.

For stone stacks, fit retainer plates to each steel pipe or use a different, suitable mounting

for the purge air unit.

3

Fitting recommendation for purge air units (duct diameter not representative)

3.3.5 Duct insulation

▸ Refit the thermal duct insulation; reinforce the insulation when necessary.

Steel pipe 50 x 5

DIN 2391

Purge air unit fastening

50 mm protrusion for circular duct cross-section

Flange 60 x 8 60

DIN 174

CAUTION: Device failure due to high ambient temperatures

The SR-unit of the GM35 is designed for a maximum ambient temperature of

+55 °C. Radiant heat on the enclosure surface can, under certain

circumstances, lead to temperatures higher than the measured air

temperature.

▸ Therefore, design insulation and radiation shielding so that temperature

limits are reliably maintained.

Loading...

Loading...