27

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

PROJECT PLANNING INFORMATION

3.3.2 Uncovering the duct

▸ If necessary, remove approx. 800 x 1500 mm (W x H) of the duct insulation to be able to

access the duct during subsequent work.

▸ Keep the insulation material removed for later refitting resp. provide new suitable

insulation material.

3.3.3 Installing the flange with tube

Notes on flange

installation

• Standard flanges and special versions

SICK delivers one flange with tube with 240 mm total length and 125 mm inner diameter

as standard. A version with 500 mm total length is available for installation locations with

thicker insulation or for stone stacks.

Special versions can be manufactured on request. Onsite flanges, including ANSI

flanges, can also be used.

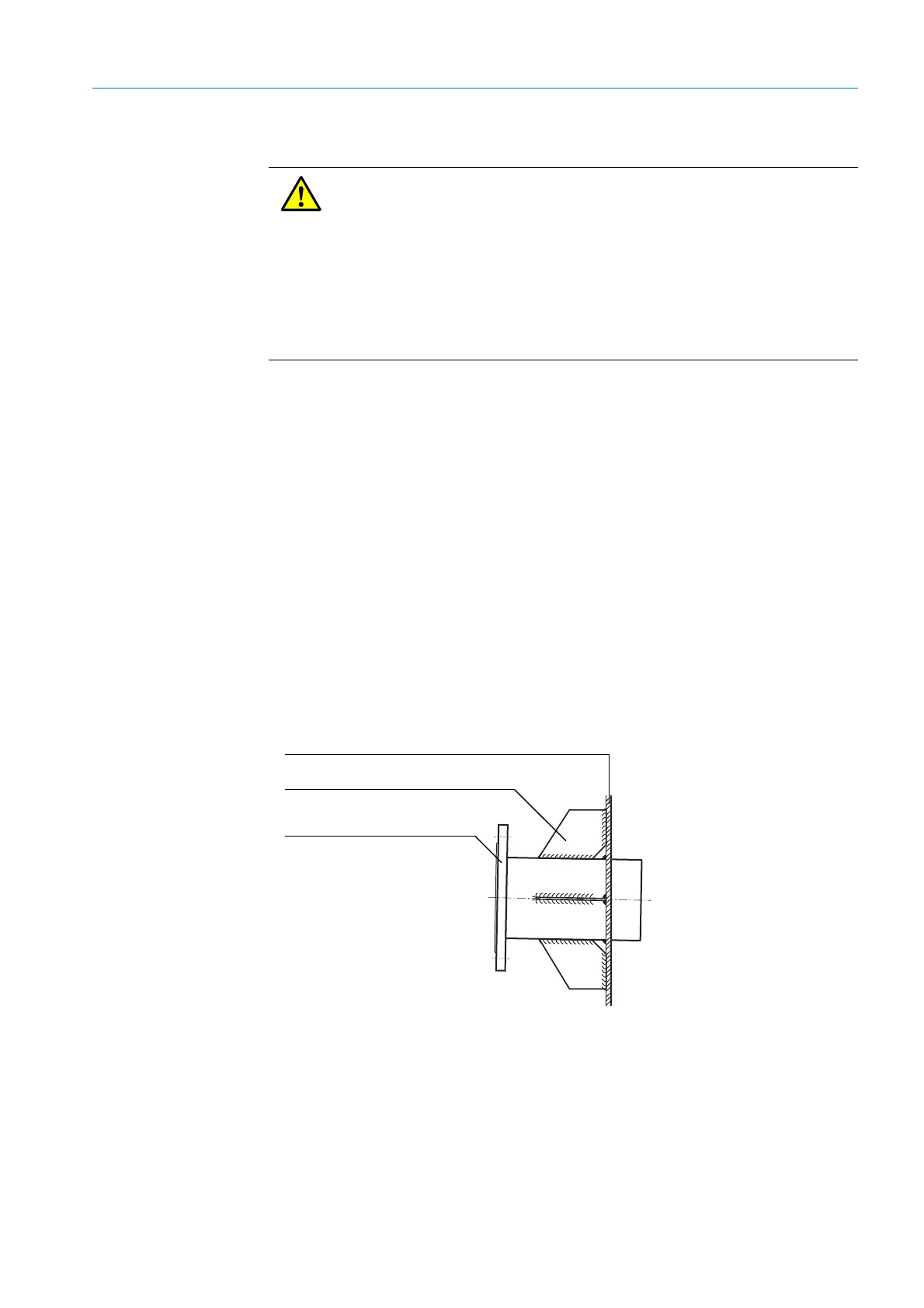

• Reinforcement with junction plates recommended

Due to the weight of the GM35 sender/receiver unit, it is recommended to reinforce the

flange tube onsite with junction plates.

Fig. 9: Reinforcing with junction plates

• Gas-carrying duct made of brick/concrete

An additional retaining plate with suitable opening should be manufactured for ducts not

made of steel and the flange with tube then welded into the opening.

CAUTION: Protective measures at the measuring point

▸ Always shut down the installation before any work on the duct!

▸ Secure parts to be separated with, for example, wire binding, to prevent

damage by falling objects.

▸ Take appropriate protective measures against hot, explosive gases or toxic

gases that could possibly escape from the duct.

▸ Always take all necessary safety precautions during welding work to prevent

explosions or fire in the duct atmosphere and on the duct insulation.

▸ If necessary, seal off the mounting flange with a cover securely until device

assembly (e.g. for overpressure in duct).

Duct wall (steel)

Reinforcing sheets (onsite)

Flange with tube

Loading...

Loading...