44

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

INSTALLATION

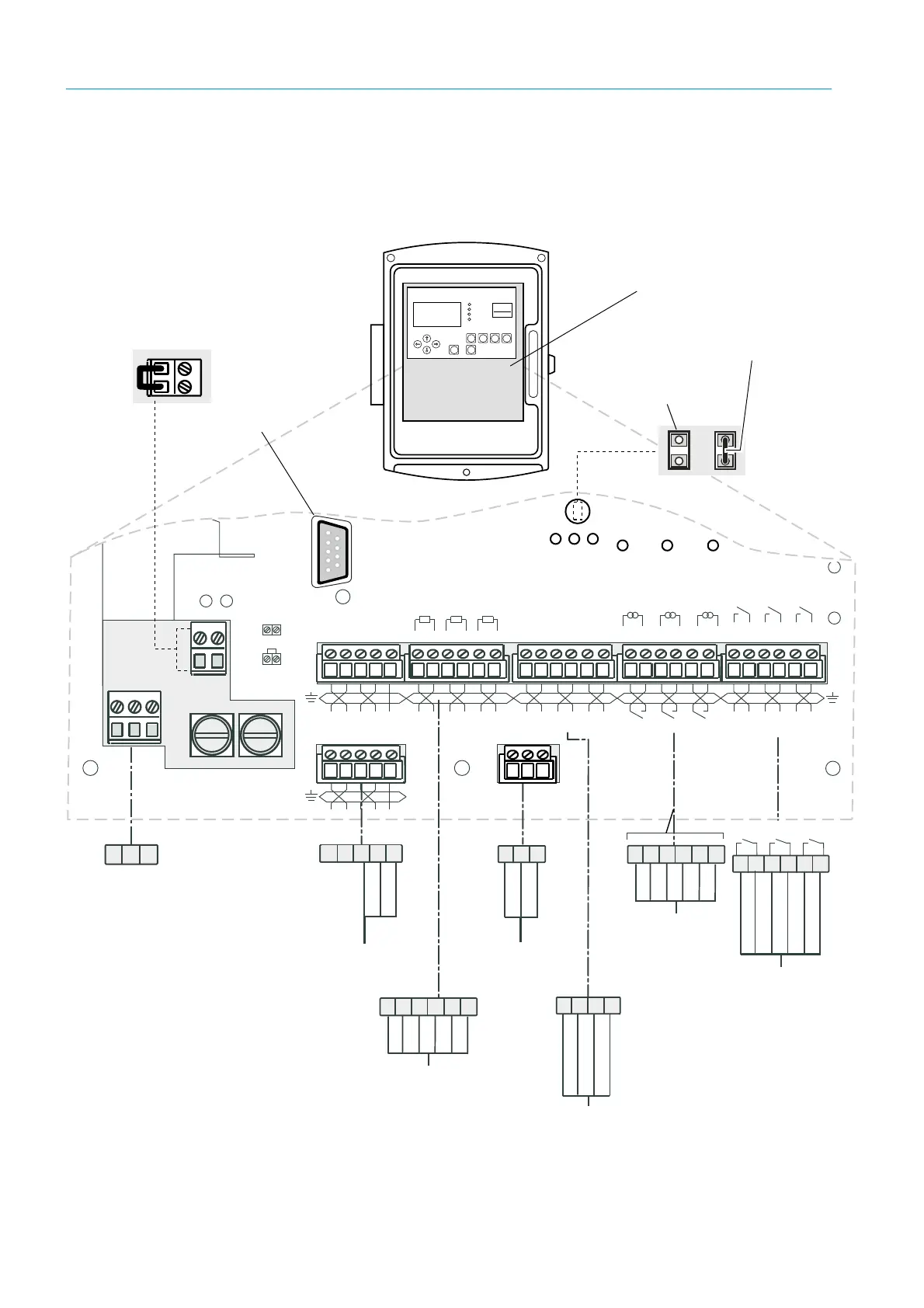

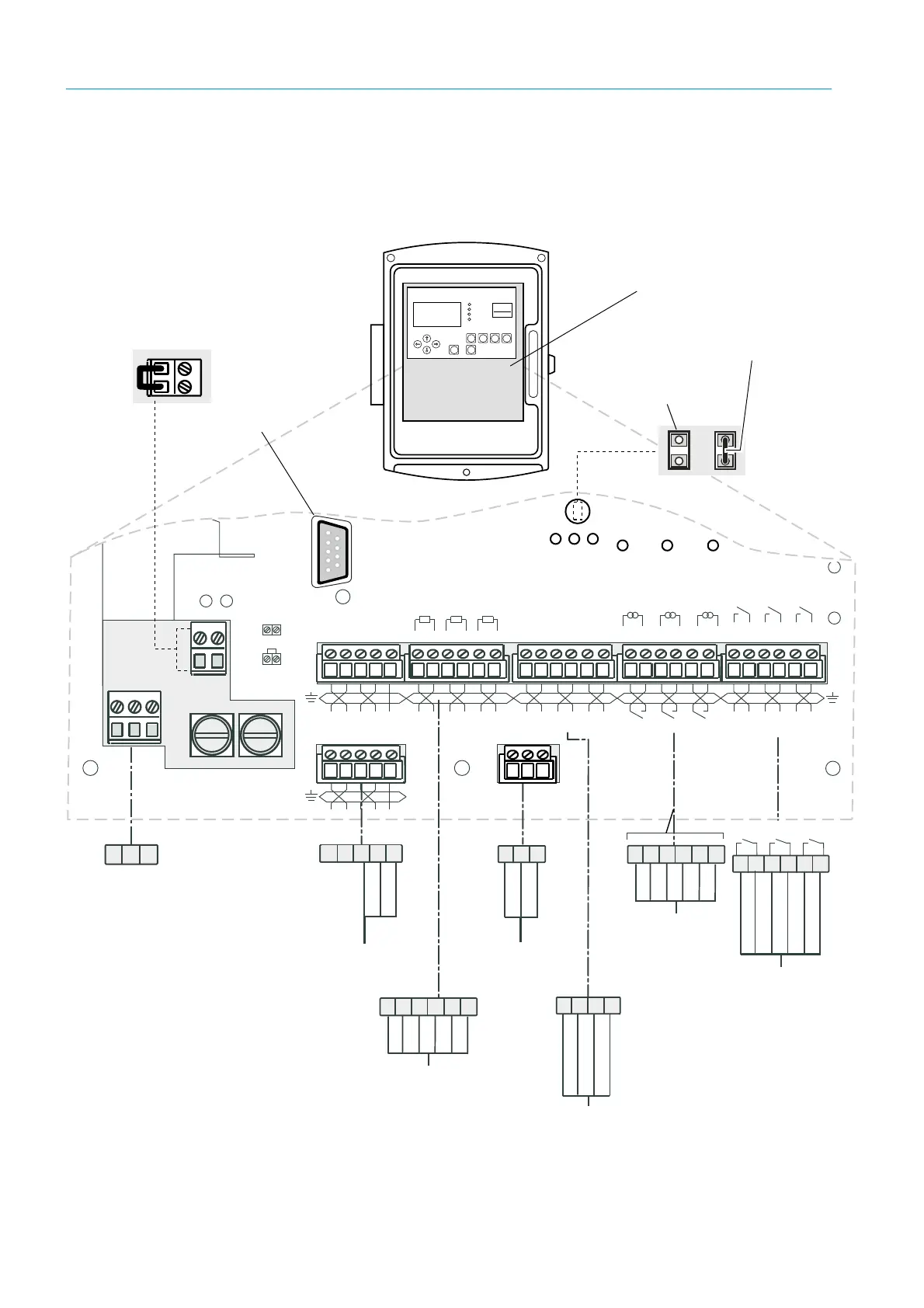

4.4.3 Electrical connection of the evaluation unit

Laying cables to the evaluation unit and the cable specifications have already been

described in

“Preparations for electrical installation”, page 30, in particular in “Cable rout-

ing diagram”, page 33.

Fig. 19: Connections on the evaluation unit (cabling provided by the customer)

+ – + – + –

+ – + – + –

+ –

+ – + –

PE

N

L1

PE N L1

V 42+

H NAC

L NAC

V 42+

H NAC

L NAC

CAN GND

CAN H

CAN L

CAN GND

+– +–+–

115/230 V AC;

50/60 Hz

(3 x 1.5

2

)

+– +–+–

12

12 3

Power

+5V +24V

Power CAN

+24V

+ – H L GND

Digital in

CAN2

Terminator

Analog in

0.. 20mA

100 100 100

40..60Hz

230V

or

115V

AO1 AO2 AO3DI1 DI2 DI3 AI1 AI2 AI3

Sensor

DO1 DO2 DO3

Digital out

AC/DC 48V 30VA 1A

Analog out

0.. 20mA

Sensor

CAN2

Fuse 2.5 AT 250V

PE N L1

Tp

Enter meas

diag par cal maint

Operation

Service

Warning

Malfunction

GM 35

Evaluation Unit

RS 232

Plug this bridge for 115 V or 120 V voltage supply.

48 V AC/DC; 60 VA,

1 A (6 x 0.75

2

)

Relay outputs

0...20 mA (6 x 0.75

2

)

Analog outputs

0...20 mA (6 x 0.5

2

)

Analog inputs

Failure

1)

Maintenance request

2)

Function control

2)

Check cycle

Free assignment

Jumper not connected

(not activated)

Connections circuit board

Cast-metal enclosure shown

1)

NC contact

2)

NO contact

Cable (twisted, shielded) to

SR-unit or terminal box

Cable (twisted, shielded)

to SCU

RS232 connection

CAN2

terminator

Jumper connected

(activated)

Loading...

Loading...