12

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

PRODUCT OVERVIEW

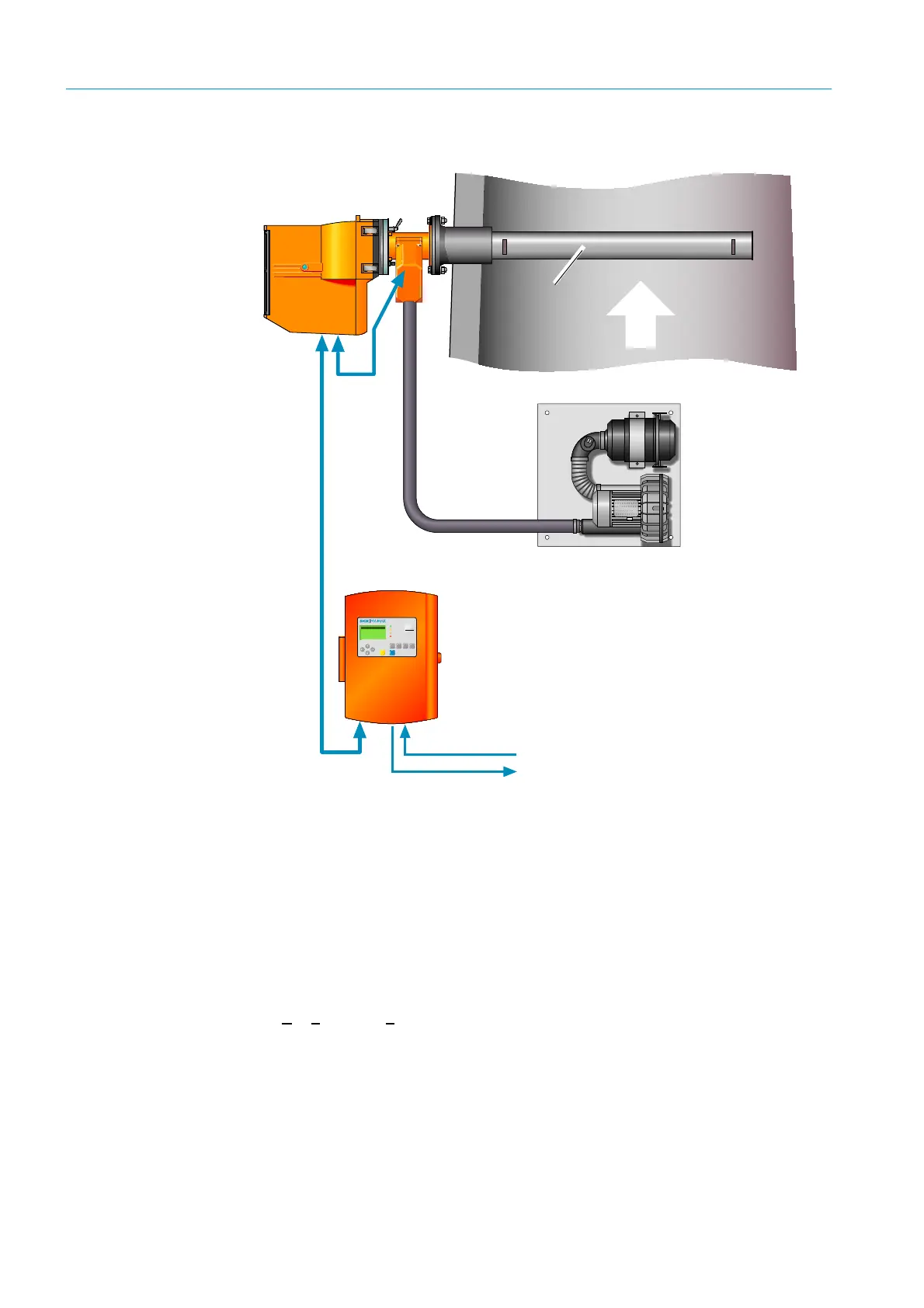

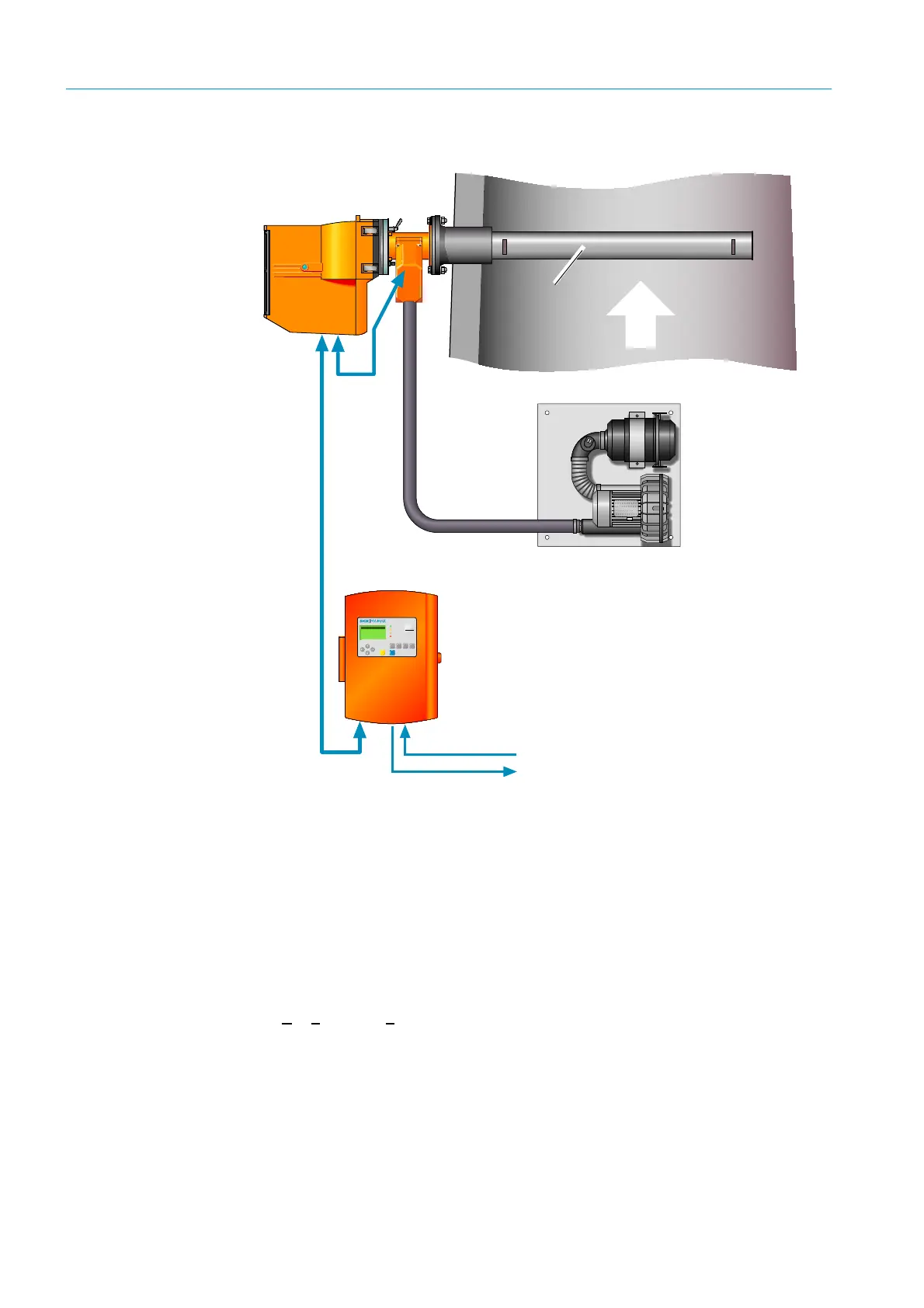

2.1.2 Overview of standard components

Fig. 1: GM35 system overview

• Sender/receiver unit (SR-unit)

Contains the main optical and electronic subassemblies of the measuring system. Records

gas concentrations, calculates measured values, measures components CO or N

2

O, CO

2

and H

2

O; both singly and simultaneously in combinations.

• Measuring probe

Measuring probes are available in open design versions with integrated purge air guidance

system (GMP) as well as versions with a gas-permeable diaphragm not requiring purge air

(GPP: G

as Permeable Probe). Both versions are described from page 14 onwards.

• Purge air unit

Provides purge air supply for the SR-unit with a GMP measuring probe (open design) and

protects against contamination and high gas temperatures. The blower types for the

SR-unit resp. reflector are designed differently depending on the application.

maintcalpardiag

GM 35

Evaluation Unit

CO

CO

2

H

2

O

mg/

m

3

236

Ref. conditions

Hum: wet

Measuring

Operation

Service

Warnin

Malfunction

Purge air unit SLV4

(not required when

using GPP measuring

probes)

GM35 sender/receiver unit

with GMP measuring probe

Temperature

sensor

Evaluation unit

EvU

CAN bus

CAN

Inputs/outputs

analog, binary

Interfaces to plant

peripherals:

•Host computer

•Sensors

• Measured data

processing

• Status signals

Loading...

Loading...