121

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

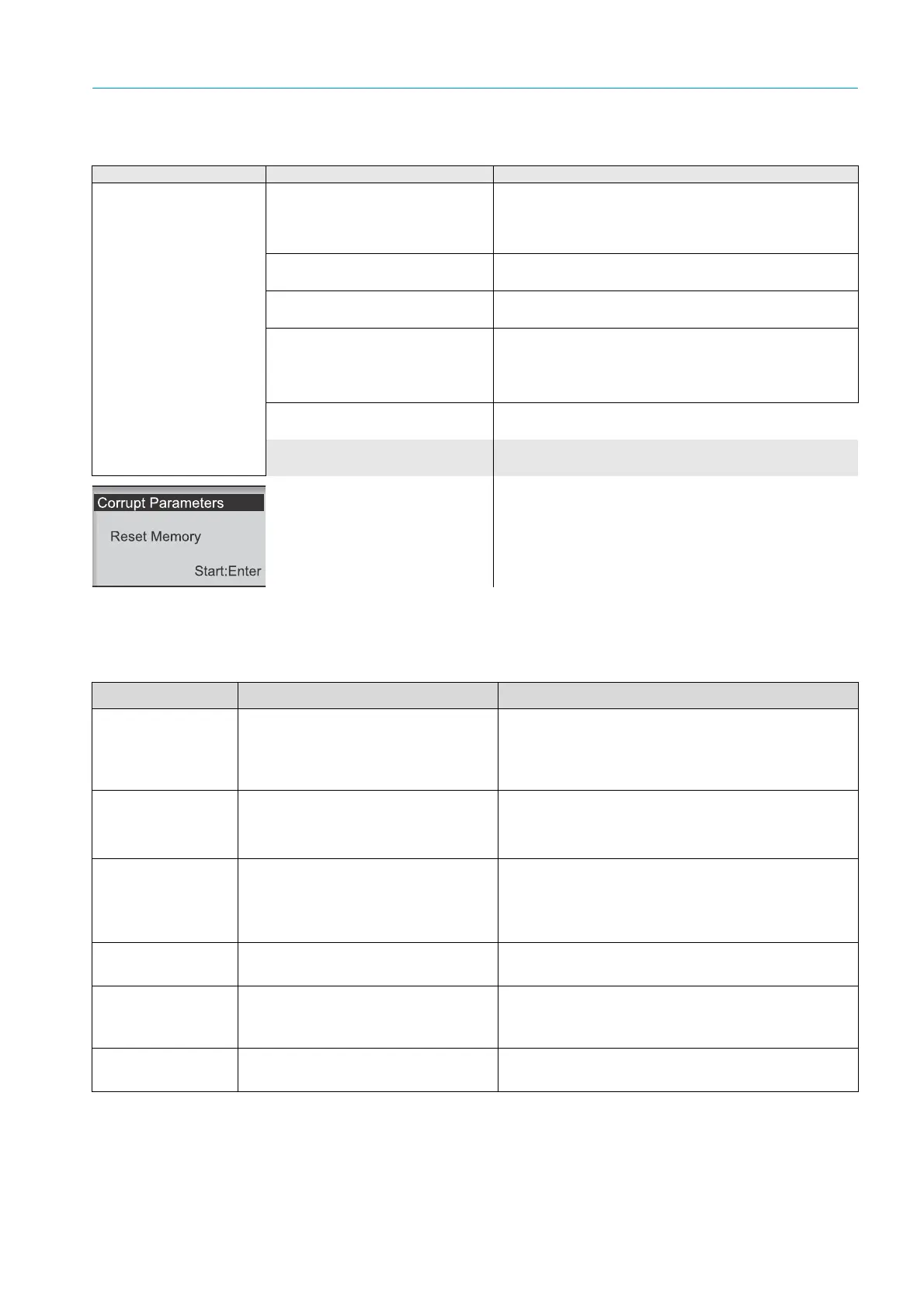

TROUBLESHOOTING AND CLEARING MALFUNCTIONS

10.3.1 Troubleshooting and clearing malfunctions, evaluation unit

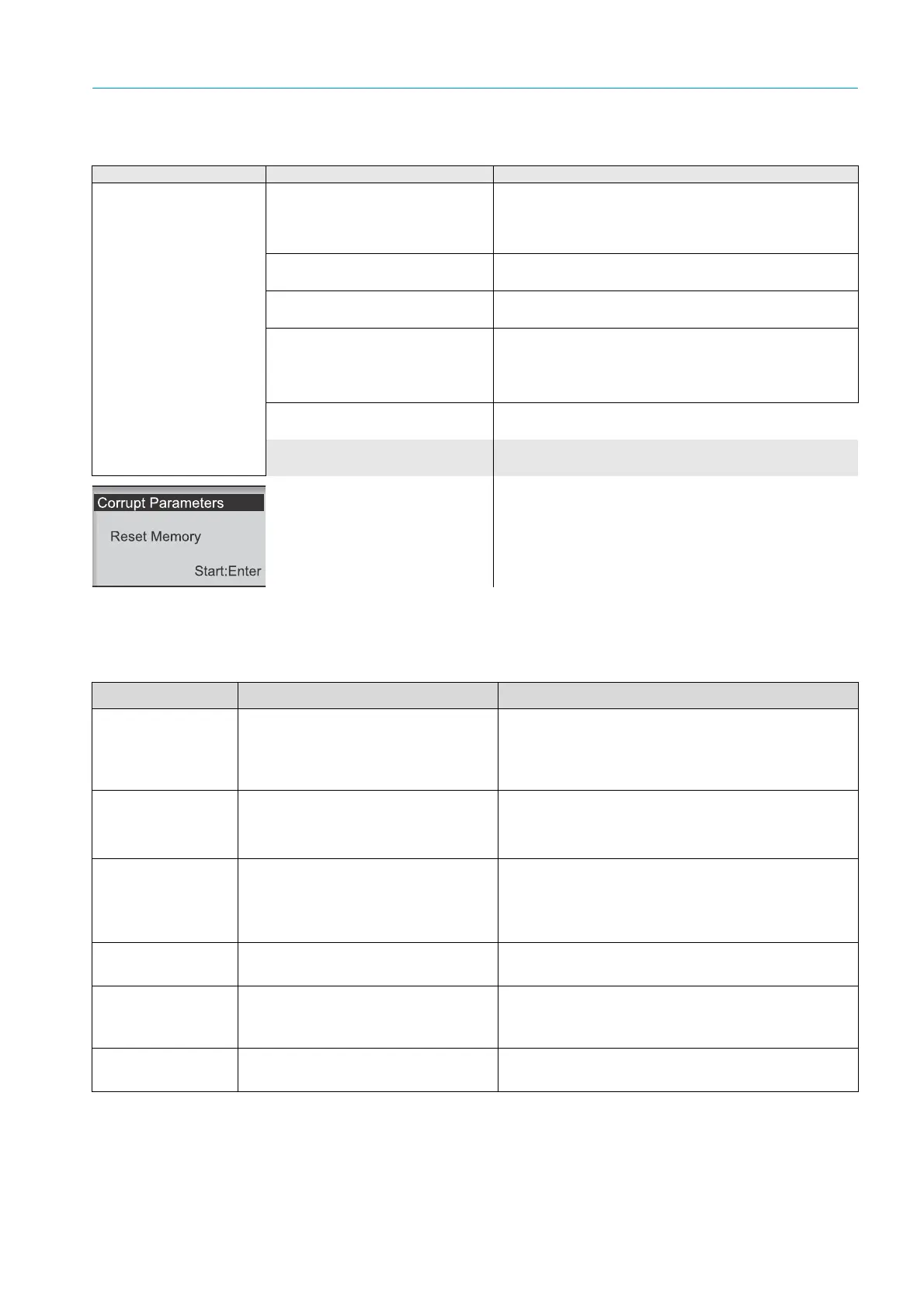

10.3.2 Error messages for the GM35 SR-unit

The following error messages, which can be displayed on the evaluation unit, refer to the

GM35 SR-unit.

Error description/message Component/possible cause Clearance

Evaluation unit not

responding

Evaluation unit:

● Evaluation unit power supply

defective.

▸ Check power supply on all system components:

– If necessary, provide power supply on site.

– If necessary, check/reconnect connections on the

system components.

Evaluation unit:

● Incorrect operating voltage.

▸ Check operating voltage set on the evaluation unit:

– If necessary, change setting.

Evaluation unit:

● Defective fuse.

▸ Check fuse in the evaluation unit:

– If necessary, replace fuse.

Evaluation unit:

● No defect localized yet.

▸ Disconnect all system components from the power

supply and reconnect one at a time.

▸ Check the CAN bus cable from the evaluation unit to the

SR-unit resp. terminal box.

Evaluation unit:

● Error occurs again.

▸ Replace the last component connected, contact

Service.

Evaluation unit:

● 24V/5V supply defective.

▸ Check 24V/5V supply, replace evaluation unit resp.

electronic board module; contact Service.

Evaluation unit:

● Inconsistent data detected in

parameter memory.

▸ Press Enter to restart the system; the factory

parameter settings are then active;

▸ If necessary, reconfigure the parameters.

▸ If the same error message occurs again, replace

the EvU and contact Service

Error message Component/possible causes Clearance

Air purge low SLV

Volume flow is below the set

threshold.

▸ Check purge air supply (blower, hoses), exchange

filter on purge air blower when necessary,

see

“Checking and replacing the purge air filter”,

page 107

.

CO Ampl. Max

N

2

O Ampl. max

CO (N

2

0) measurement amplifier

above dynamic range.

▸ Check alignment;

see page 111.

▸ Cleaning optical interfaces,

see page 104.

▸ Contact Service.

CO com.

N

2

0 com.

CO

2

/H

2

O module not connected to CO

(N

2

0) module.

▸ Check cable connection and correct seat of the

plug connection; repair in the GM35 when

necessary

▸ If the error cannot be cleared: Contact Service.

CO CUVETTE com.

N

2

0 CUVETTE com.

CO (N

2

0) module not connected to CO

cell motor.

▸ Contact Service.

CO CUVETTE range

N20 CUVETTE range

● CO (N

2

0) duct in reference cycle

outside expected range.

● CO (N

2

0) cell may be leaking.

▸ Exchange the measurement module or contact

Service.

CO div. Zero

N

2

0 div. zero

CO (N

2

0) module adjustment data

invalid.

▸ Contact Service.

Loading...

Loading...