77

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

START-UP

7.3 Mechanical preparations for the SR-unit and reflector

7.3.1 Checking the scope of delivery

▸ Check the exterior of the SR-unit and measuring probe to ensure they are not damaged.

▸ Make sure the supply voltage on the type plate of the SR-unit complies with the plant

conditions.

▸ If a GPP measuring probe is to be used, also check the supply voltage specified on the

type plate of the measuring probe.

The supply voltage of the GM35 SR-unit and measuring probe can be changed between

115 V and 230 V on site by the SICK Service when necessary.

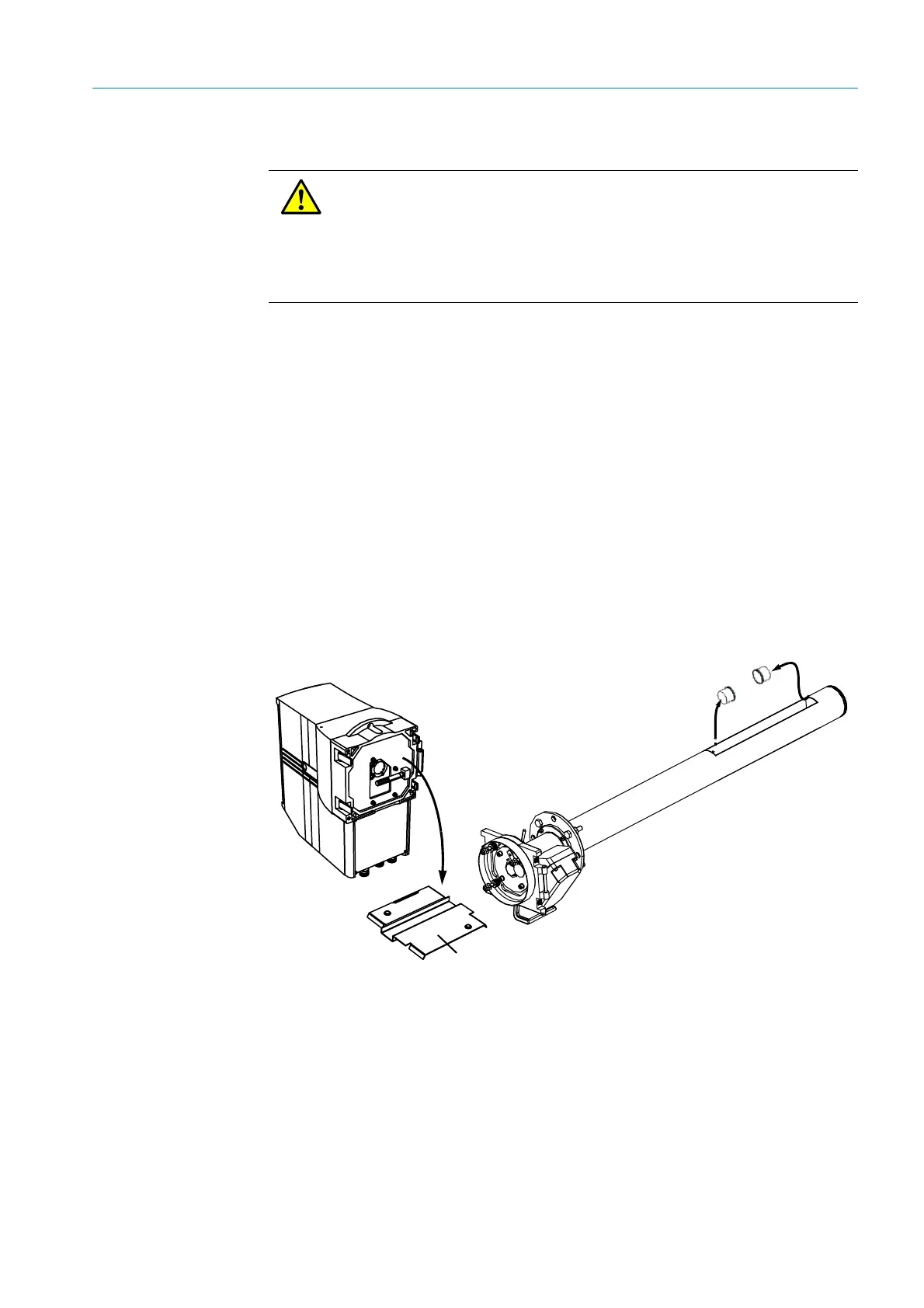

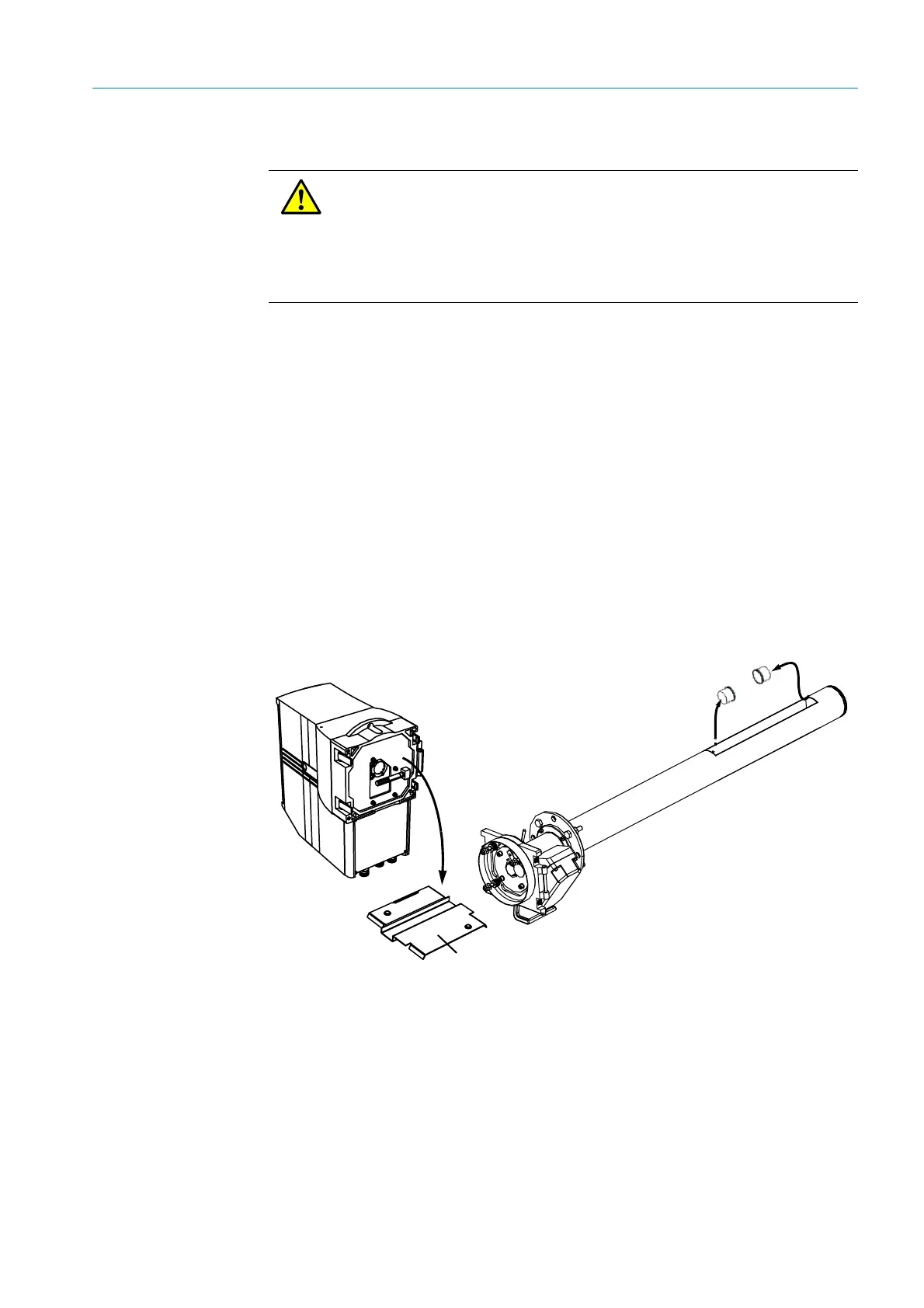

7.3.2 Transport safety devices

▸ Remove the transport safety devices shown below as well as any protective stickers,

marked as such, depending on the device version.

▸ The front cover of the SR-unit is clamped between the flange fixture and enclosure. To

remove it, open the four quick-release fasteners and swivel the flange fixture up (see

Fig.). Keep the transport safety devices as required.

Fig. 48: Transport safety devices to be removed from the SR-unit and measuring probe

WARNING: Avoid hazards through sample gases!

To avoid health hazards, the following work step may not be carried out during

the preparation described in this Section but first within the scope of the

respective descriptions in the following Sections.

– Connecting the power supply to the SR-unit

– Fitting an angle flange or the measuring probe on the sample gas duct

Plastic protective caps on the

openings in the measuring gap on

GMP measuring probes

SR-unit front cover

Loading...

Loading...