Chapter 3

MSC800

8011540/14B8/2019-06-06 Operating instructions | SICK 31

Subject to change without notice

In this case, the distance between the sensors determines the size of the reading field.

The reading process can alternatively be controlled with command strings via the data

interface. The output of the read results is either carried out at the end of the read cycle

(the rear edge of the object has left the end of the reading field) or even during the read

cycle if certain configurable conditions are met.

Tracking operation

In the internal tracking operation, there are a maximum of 10 objects behind each other in

the reading field at the same time during the reading process, i.e., the read codes must be

able to be clearly assigned to the objects.

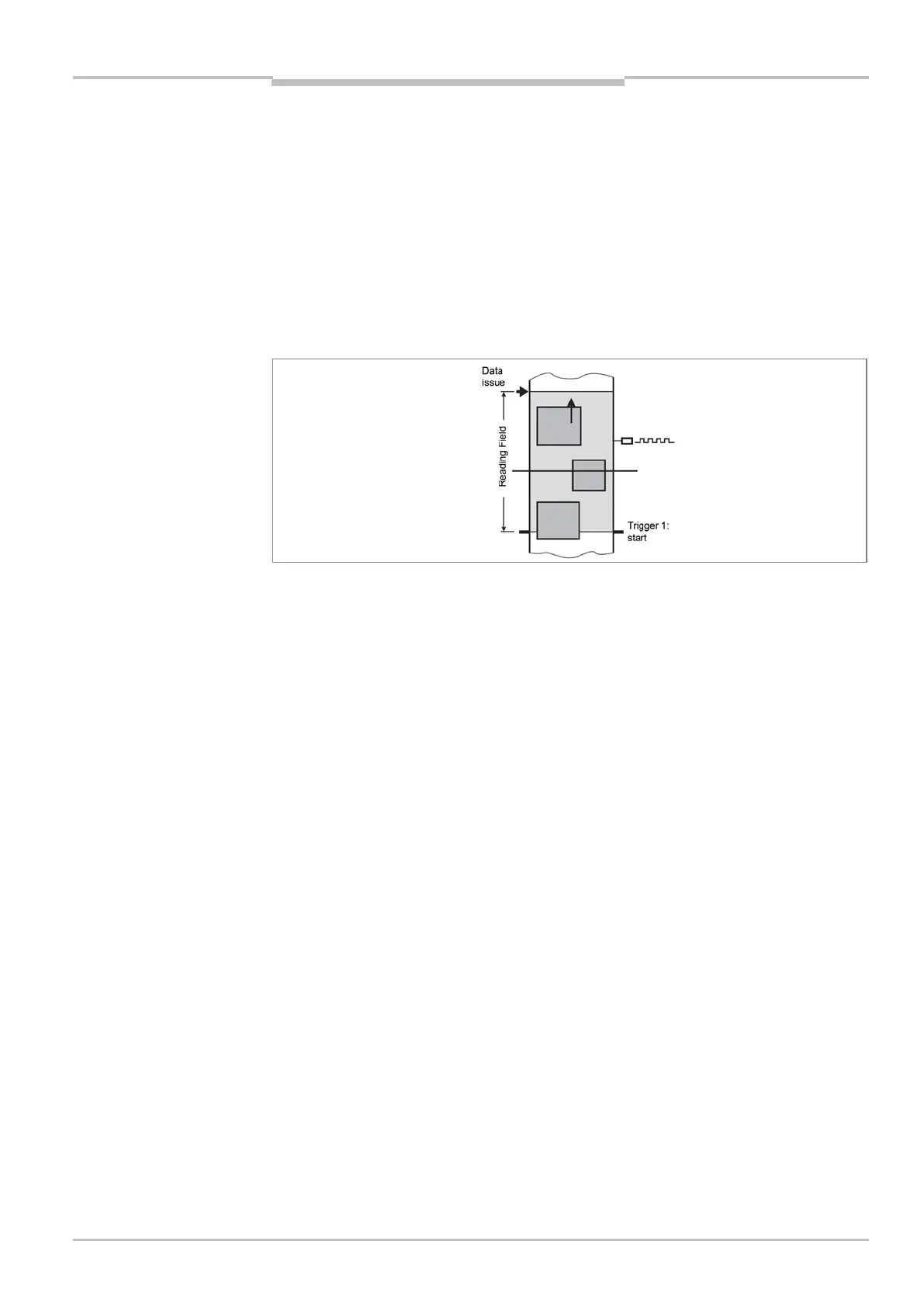

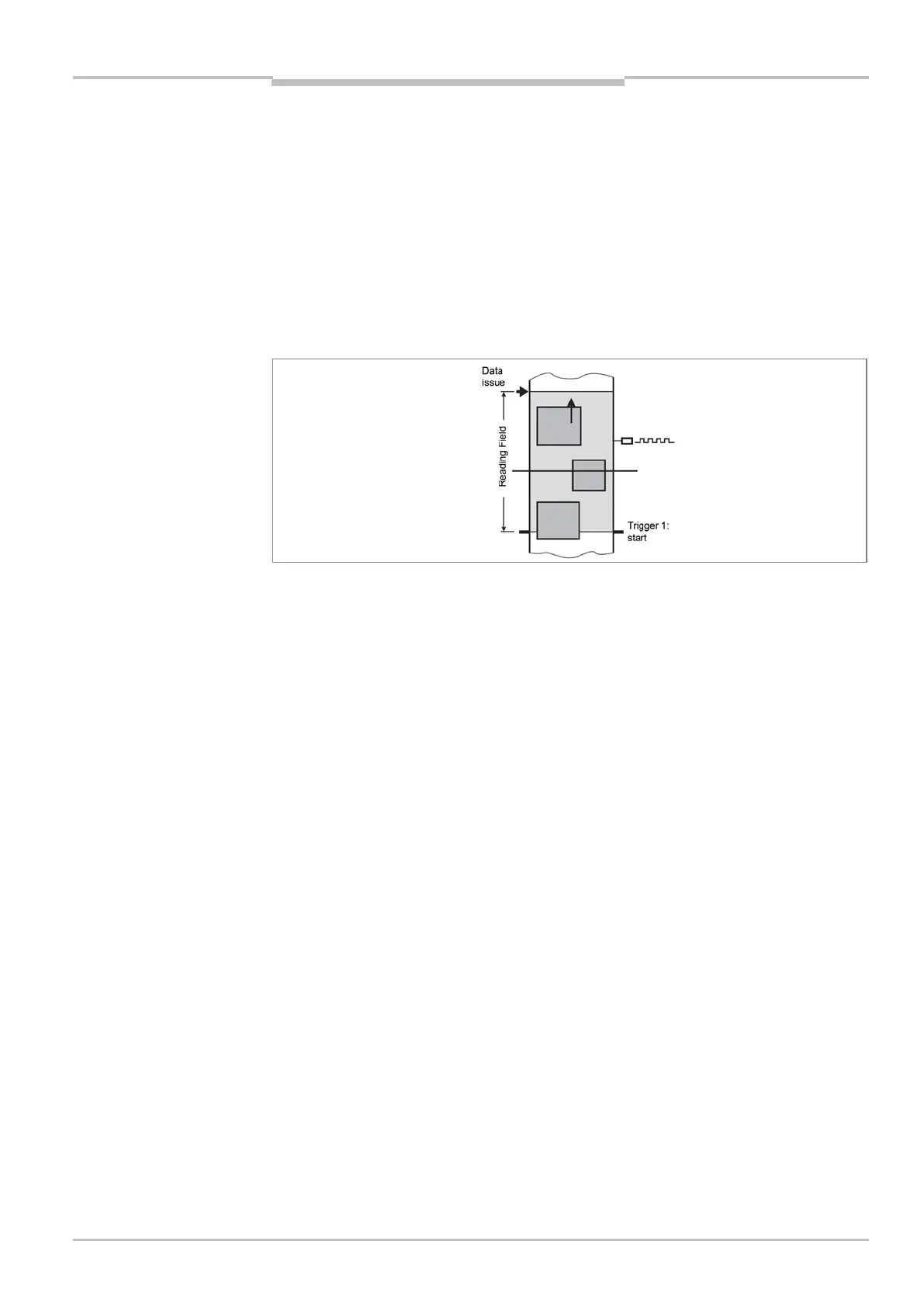

Fig. 10: Read operating modes (tracking operation), side reading from above

As standard, the start of the reading process is controlled by a read cycle sensor at the

start of the reading field (see chapter 3.4.1 Object trigger control on page 29), the end

defines the specification of the object release point. This also defines the size of the

resulting reading field.

In order to be able to track the transport of the objects in the reading field, a regular clock

is required. This is generated by the external incremental encoder, which constantly

provides at least one pulse per 10 mm movement in the conveyor direction (see chapter

3.4.3 Increment configuration on page 29). This provides a clear temporal representation

of the route between the read cycle sensor and object release point. Jittering when the

conveyor technology is starting up or in the event of slowing down when there is a high

load with lots of objects to convey is therefore also recorded. A gap of at least 50 mm is

necessary for clear separation of successive objects. The issuing of the read result for an

object is carried out after the rear edge of the object passes the object release point. The

reading process can alternatively be started with a command string via the data interface.

The SOPAS-ET configuration software can be used to configure the read operating mode,

the object release point, and the time of issuing the read result:

PROJECT TREE, MSC800, PARAMETERS, DATA PROCESSING, tab TRACKING

PROJECT TREE, MSC800, PARAMETERS, DATA PROCESSING, OUTPUT CONTROL

Loading...

Loading...