Operating Instructions 7-19 M90 Fusion Splicer

Issue 02/97 Troubleshooting and Care/Maintenance

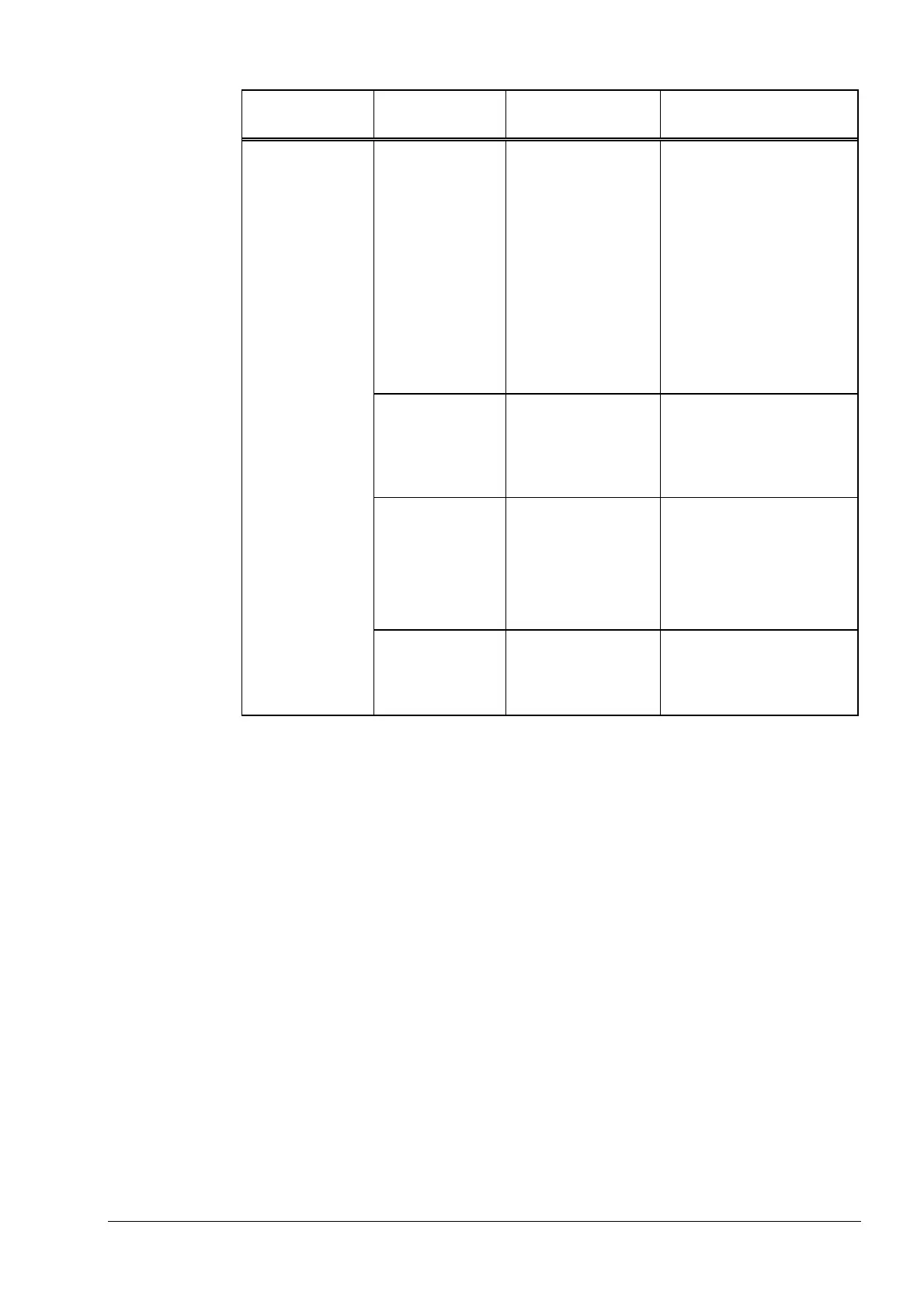

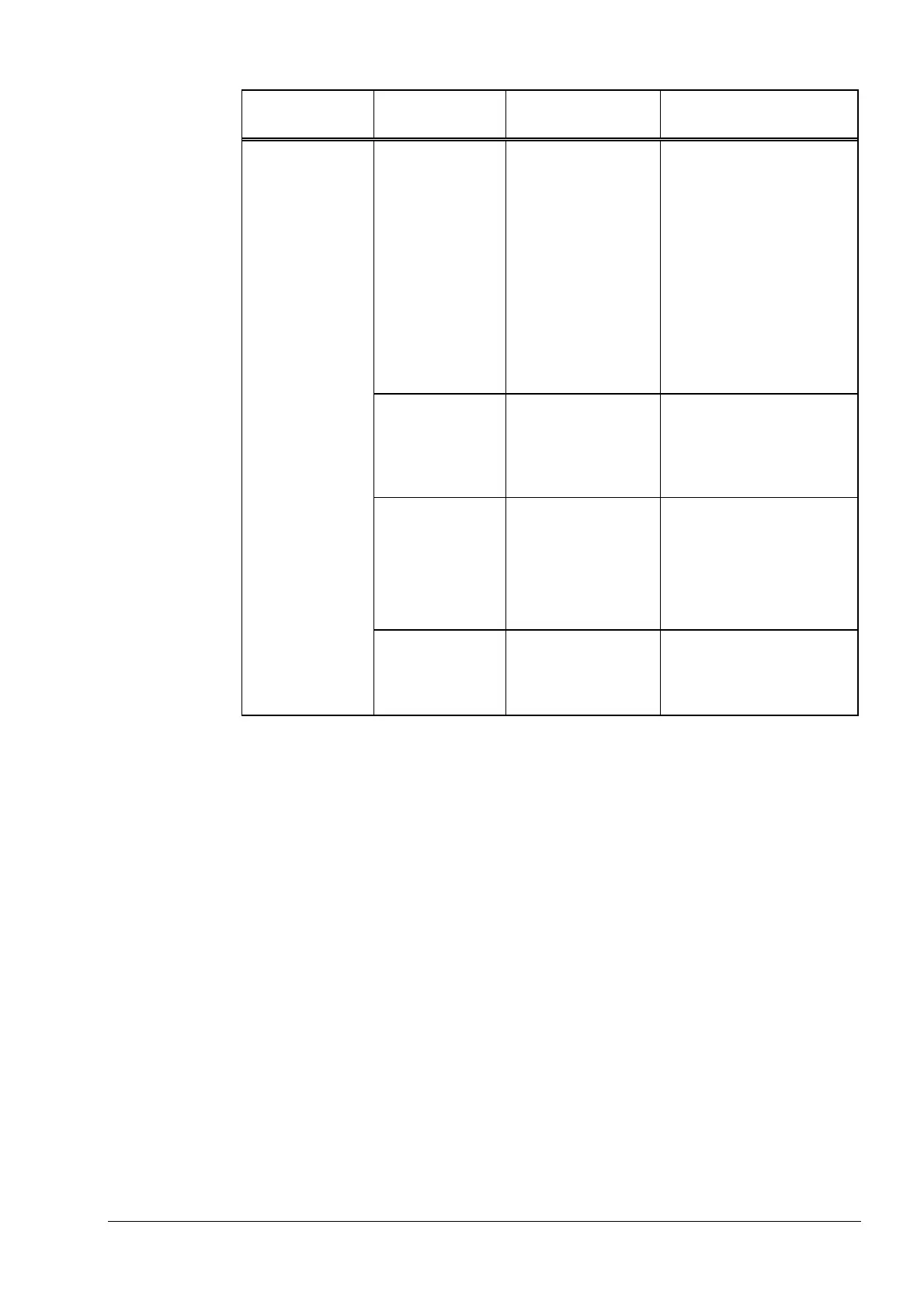

Fault Message

Fault Symptom

Possible Cause Fault Locating Remedy

Fault messages

during splice

analysis

Measurement

inpossible

(LID system)

LID system dirty. Select

Manual fiber

adjustment

from

the menu. Insert a

continuous fiber in

the LID transmitter

and LID receiver

and observe the

level displayed. This

level must stabilize

a few seconds after

the flaps are closed,

otherwise the LID

must be cleaned.

Clean the LID transmitter

and LID receiver as de-

scribed in section "Care

and maintenance". Clean

the contact face of the

mandrel and the mandrel

itself over its entire length.

Use alcohol as a solvent if

necessary.

Fiber coating is

too soft causing

fiber axes to

deviate from

straight.

Use the 900-µm guides. If

this is not possible, you

can use one of the video

programs.

Fiber guides dirty

or damaged.

Clean the guides. Use

alcohol as solvent if nec-

essary. Exchange dam-

aged guides.

Ensure there is no dirt

under the guides.

Poor cleave

quality

The

Bad cleavage

fault message ap-

pears relatively fre-

quently.

As for

Bad cleavage

.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...