M90 Fusion Splicer 7-20 Operating Instructions

Troubleshooting and Care/Maintenance Issue 02/97

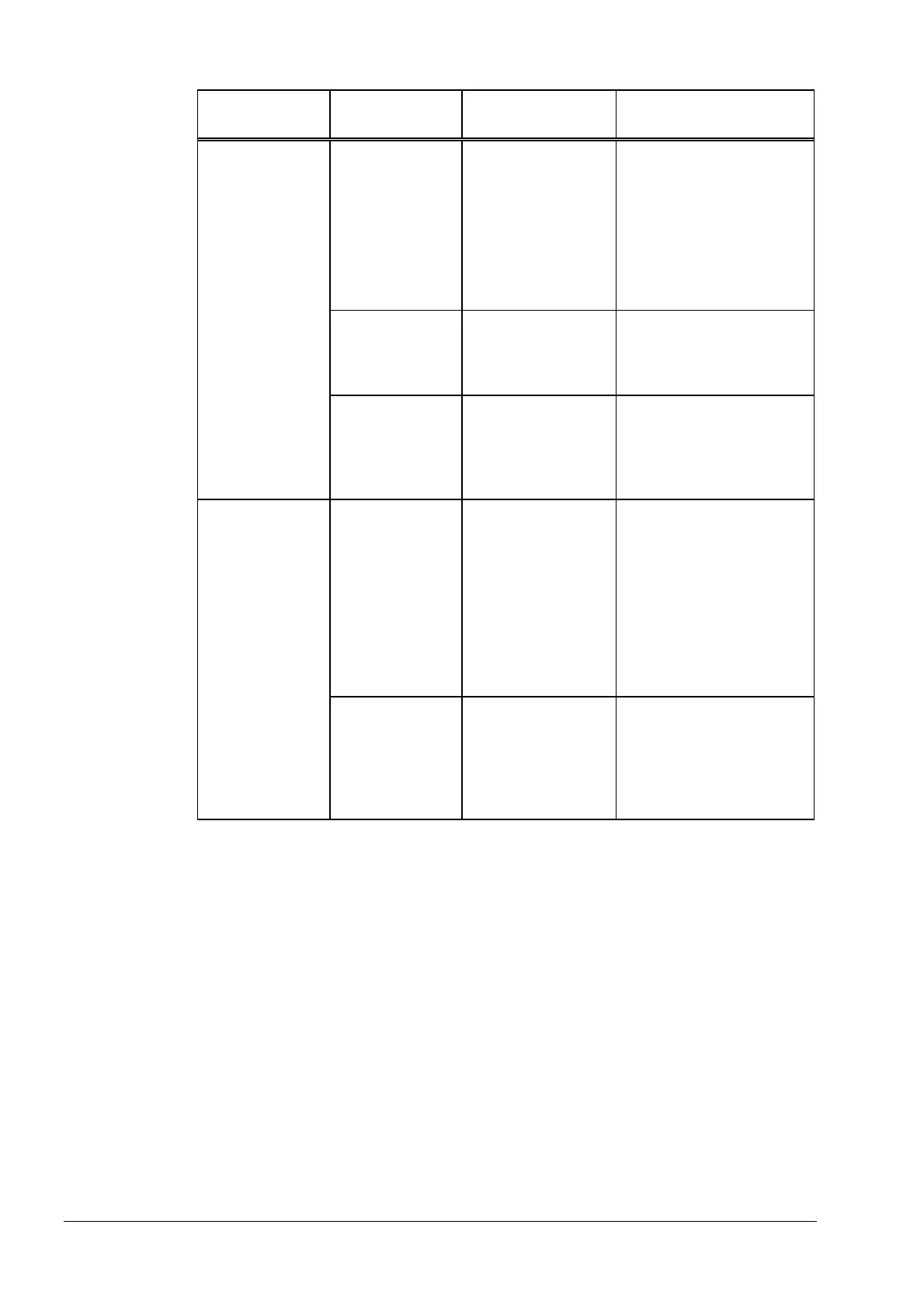

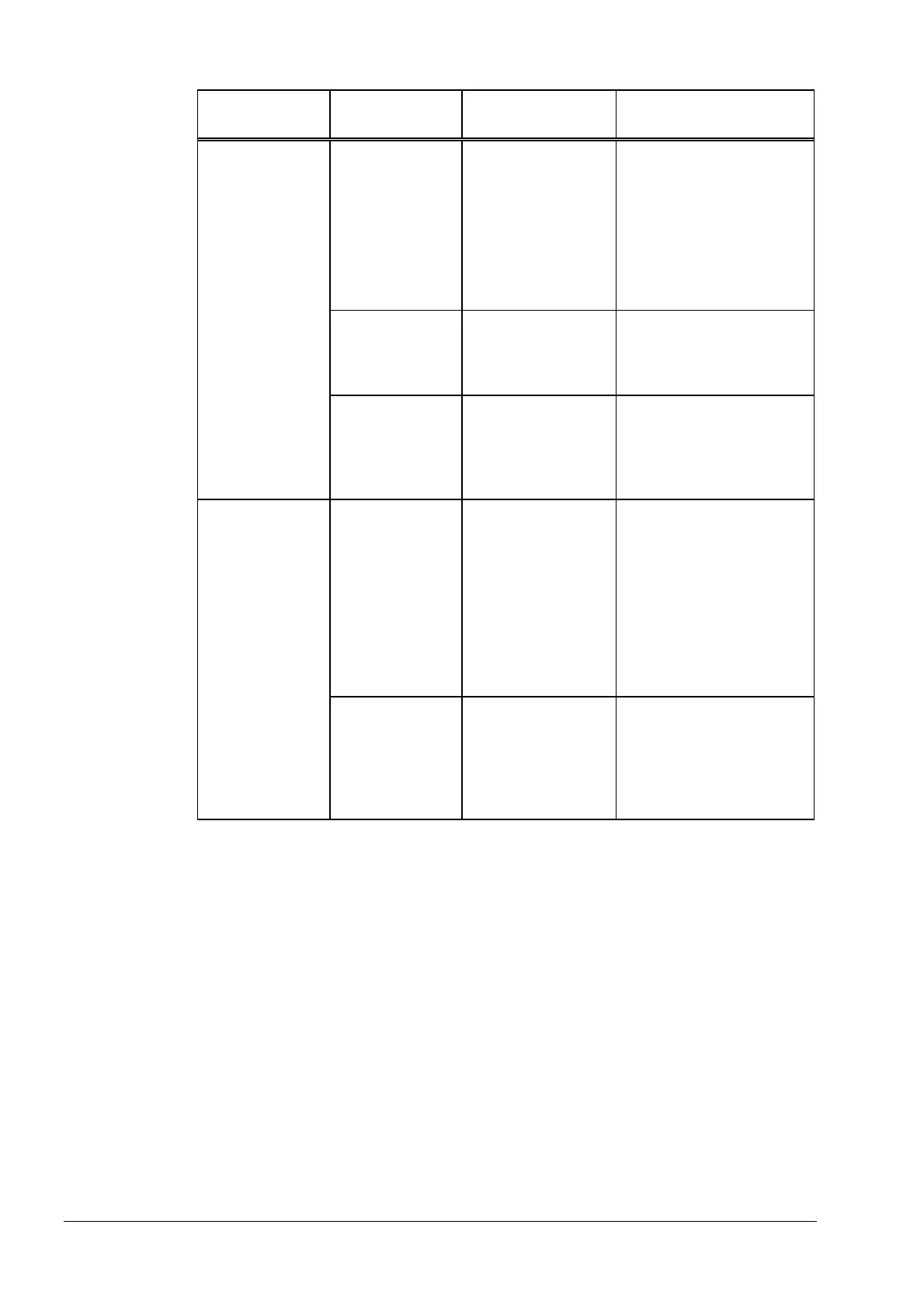

Fault Message

Fault Symptom

Possible Cause Fault Locating Remedy

Fault messages

during splice

analysis

Bad splice -

fuse again?

The actual at-

tenuation can still

be very good

under some cir-

cumstances

(video system)

Unfavorable

splicing parame-

ters.

Reduce the prefusion cur-

rent or prefusion time. The

prefusion time must not be

set too low (default setting:

0.25s).

Unfavorable fiber

type or different

fiber types on

both sides.

Use an LID program if

possible.

Dirt in the optical

system.

Check the monitor

image without fibers

inserted to see if

there are any signs

of dirt.

Ensure there is no dirt

visible on the lenses or

mirror in the area of the

electrodes or on the illumi-

nation LEDs.

Fault messages

during the tension

test

Tensile test

failed

Fiber has frac-

tured.

Ascertain whether

the fiber has frac-

tured at the splice

point or next to it.

With fibers now widely

used, fractures at the

splice point itself generally

only occur if the parameter

settings are extremely

unfavorable.

If the fracture has occurred

next to the splice point, the

stripping tool is most likely

to be faulty.

Fibers slips in the

LID system.

The fiber is not

really fractured.

Clean the LID system to

remove any excess index-

matching fluid. The index-

matching fluid should only

occur in the area of the

mandrel or coupling faces.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...