Operating Instructions 7-7 M90 Fusion Splicer

Issue 02/97 Troubleshooting and Care/Maintenance

This level curve is typically the result of non-optimally set splice parameters. The level

falls sharply just before the start of the main fusion. The reason for this is inadequate

heating of the fiber during prefusion, i.e. the prefusion time is too short, the prefusion

current too low or the fiber feed is too great. Since the transmitted level during the main

fusion continuously rises and reaches its saturation within the usual time, i.e. still dis-

played on the monitor, the main fusion current is correctly set.

The parameters prefusion current, prefusion time and fiber feed must be checked and,

if necessary, corrected in terms of higher current, longer time and smaller feed. In order

to follow the effect of the parameter change, it is advisable to change only one parame-

ter per trial. The aim of the parameter setting must be to achieve a sequence corre-

sponding to the figure "Normal Splice Sequence".

Assessing the cleave quality

Assessing the cleave quality is likewise performed using the menu "LID profile display".

The splicer must be ready for splicing, i.e.

two correctly prepared fibers must have been

inserted in the fiber guides and all flaps must have been closed

. After the splicing proc-

ess has been started, the menu is then activated.

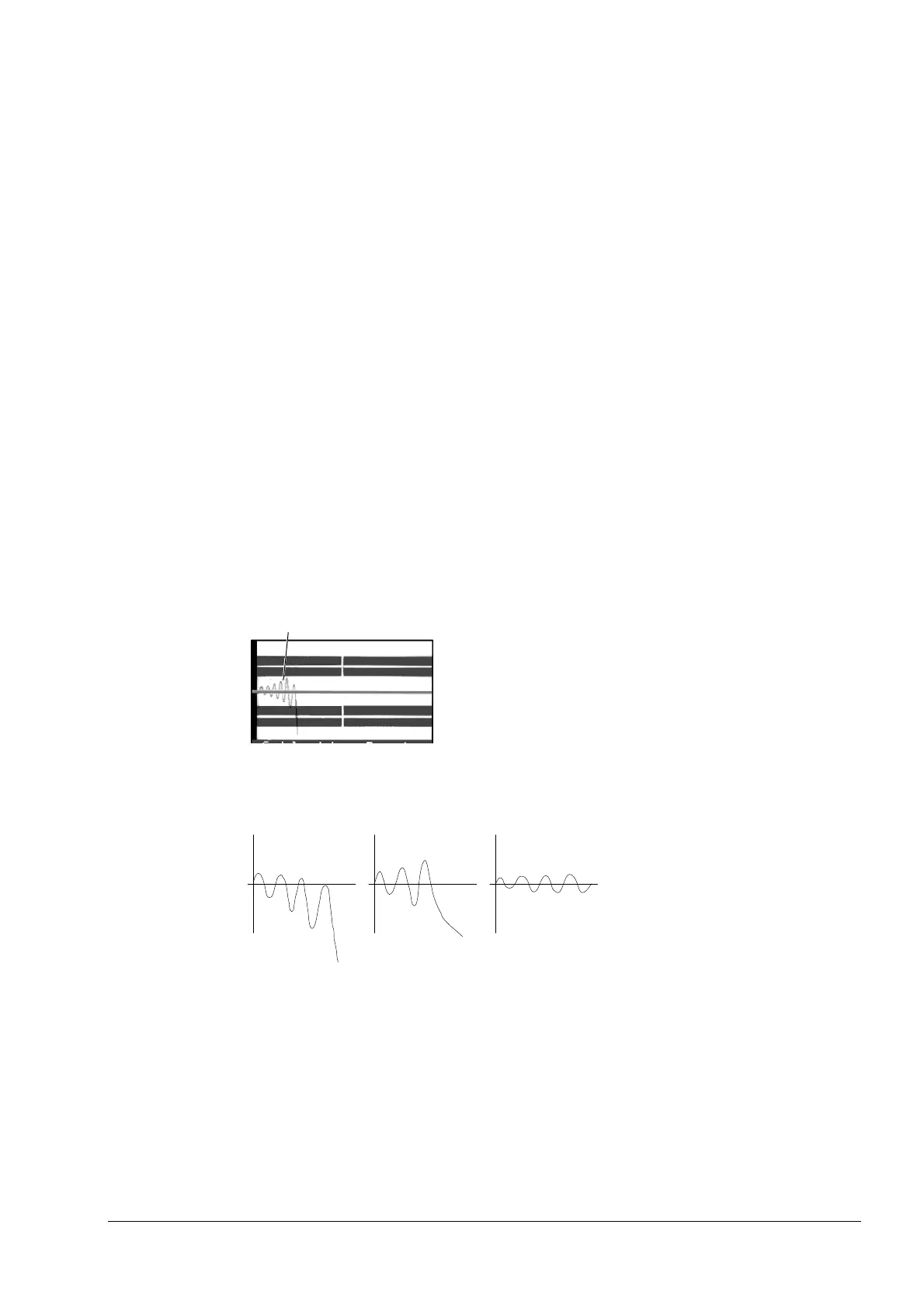

The figure "Splice Sequence for Cleave Angle Error" shows a level curve resulting from

poor quality of the fiber ends. Unlike the case with correct fiber ends (figure "Normal

Splice Sequence") the level falls sharply during the Z positioning, the splicer interrupts

the splicing process and produces a fault message. Level curves declining in this way

or oscillating only with low amplitude (see figure "Splice Sequences for Poor Fiber

Ends") occur typically with poor end faces.

7 Z positioning with cleave angle error

Splice Sequence for "Cleave Angle Error"

Splice Sequences for Poor Fiber Ends

In this case the cleaver must be cleaned in accordance with the Operating Instructions.

If, despite careful cleaning, the results are still poor, the diamond is probably defective.

It must be exchanged, an operation that may only be performed under clean environ-

mental conditions. It is advisable to have the cleaver serviced at the service center.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...