Requirements

• The synchronization interval must be set to 20 ms for the master and for the ET 200iSP.

• For time stamping you need the electronic module 8 DI NAMUR with the conguration

"8 DI NAMUR". Time stamping is not possible with all other congurations of the electronic

module 8 DI NAMUR.

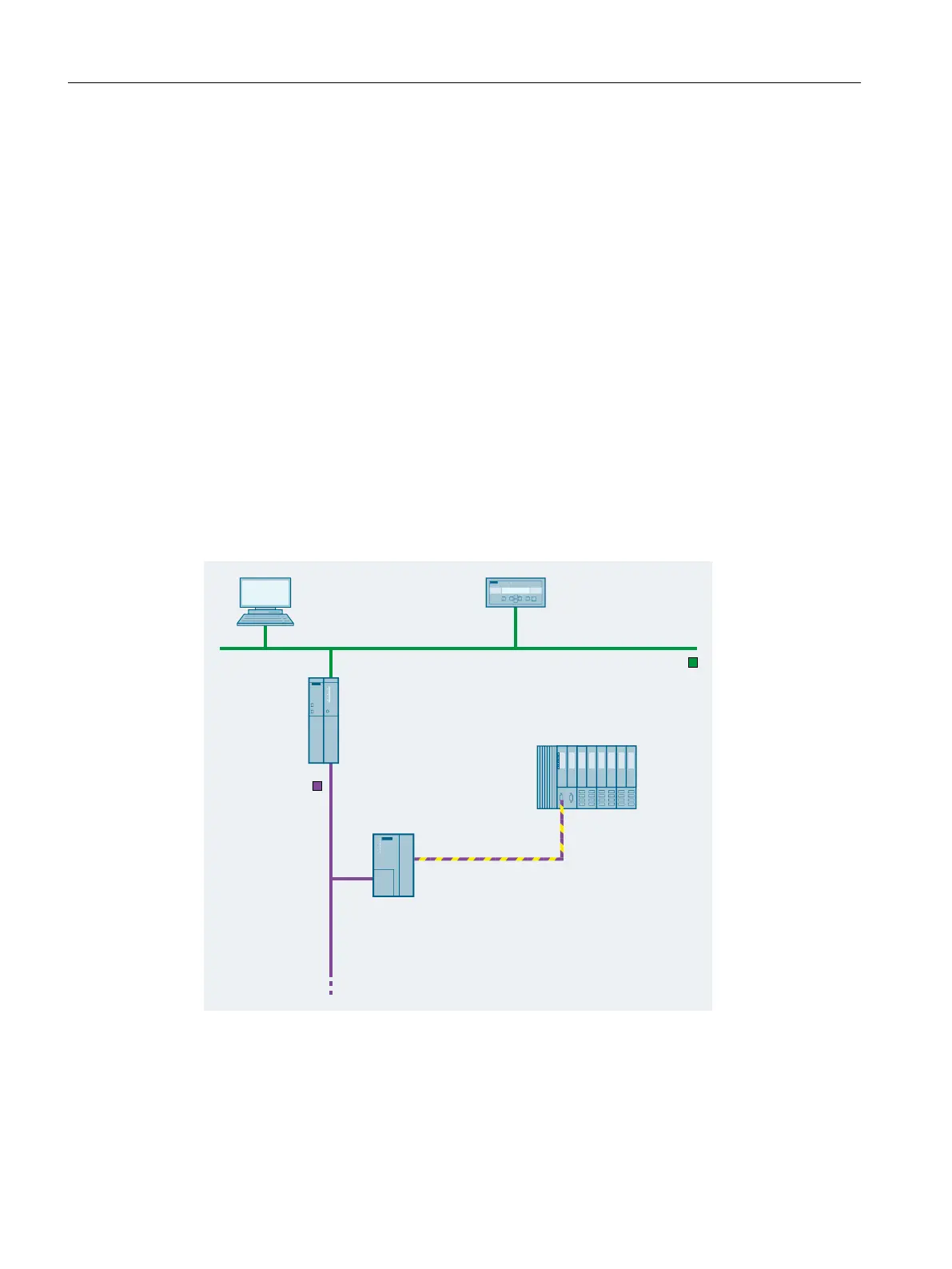

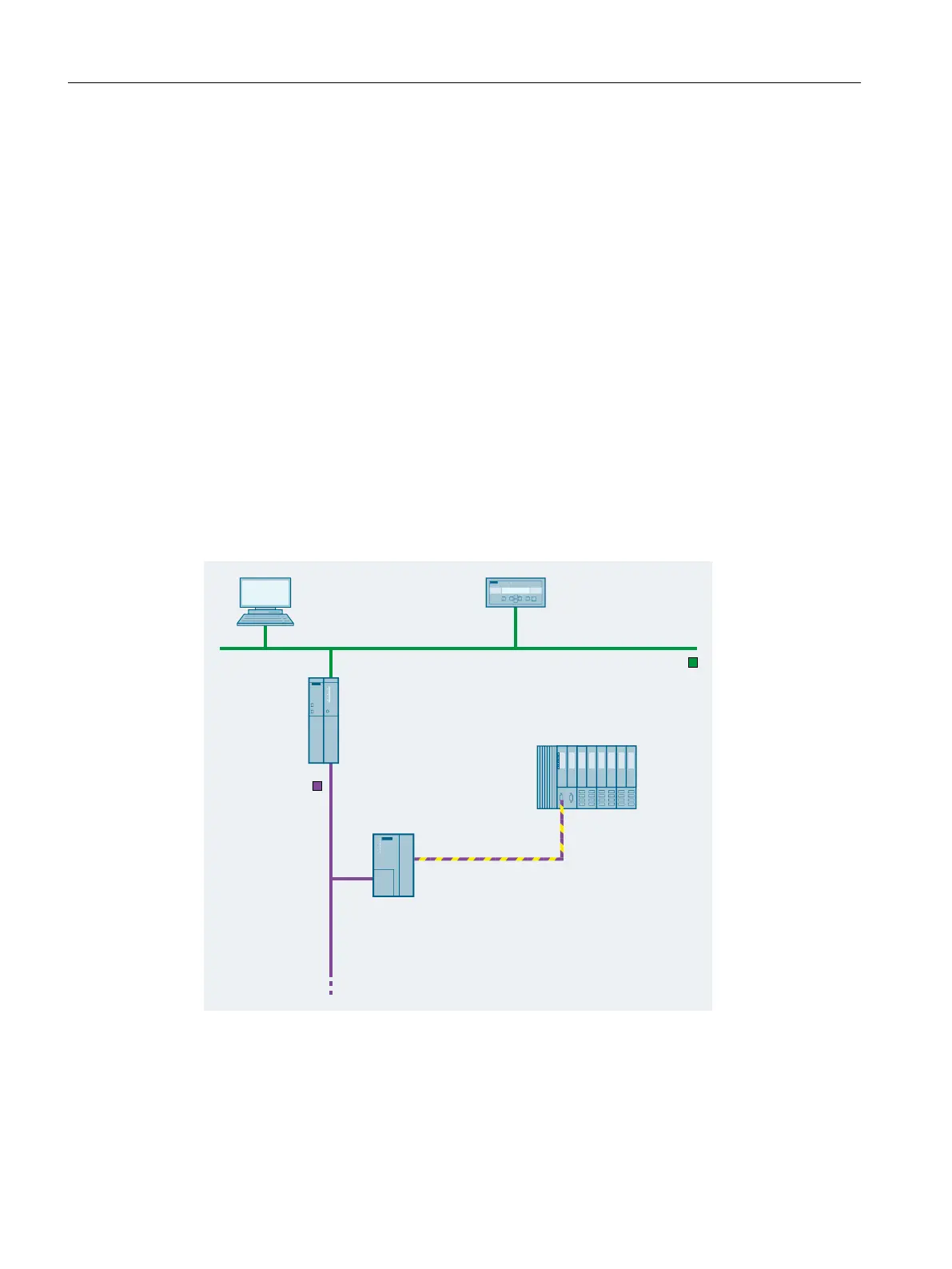

How time stamping works

In a system, you can monitor digital inputs for signal changes using conguration in HW Cong.

The following are monitored: "Incoming/outgoing signal" (as "rising or falling edge"). The

interface module stamps these changed input signals with the current time (time stamping) and

stores them as message lists. A message list is a data record with a maximum of 20 messages

about time-stamped signal changes. The interface module can store up to 15 data records.

After a certain time and if there are messages or if a data record is full, the interface module

triggers a hardware interrupt at the CPU (IO controller/DP master). The CPU then reads the data

record and forwards the message lists to an OS using the driver block FB 90 "IM_DRV".

Time stamping example

34*4DPVQMFS

%JHJUBMJOQVUT

"VUPNBUJPOTZTUFN

QMBOUWJTVBMJ[BUJPO

*OEVTUSJBM&UIFSOFU

5JNFPGEBZTFOEFS

&5J41

4

8JO$$

0QFSBUPS4UBUJPO04

4*$-0$,

130'*#64%1

Figure 4-8 Example for time stamping and edge evaluation

Congurations (principle)

4.16 Time stamping

ET 200iSP

90 Operating Instructions, 11/2022, A5E00247483-AK

Loading...

Loading...