Wiring

6.6 Wiring rules

Distributed I/O system

System Manual, 09/2019, A5E03576849-AJ

99

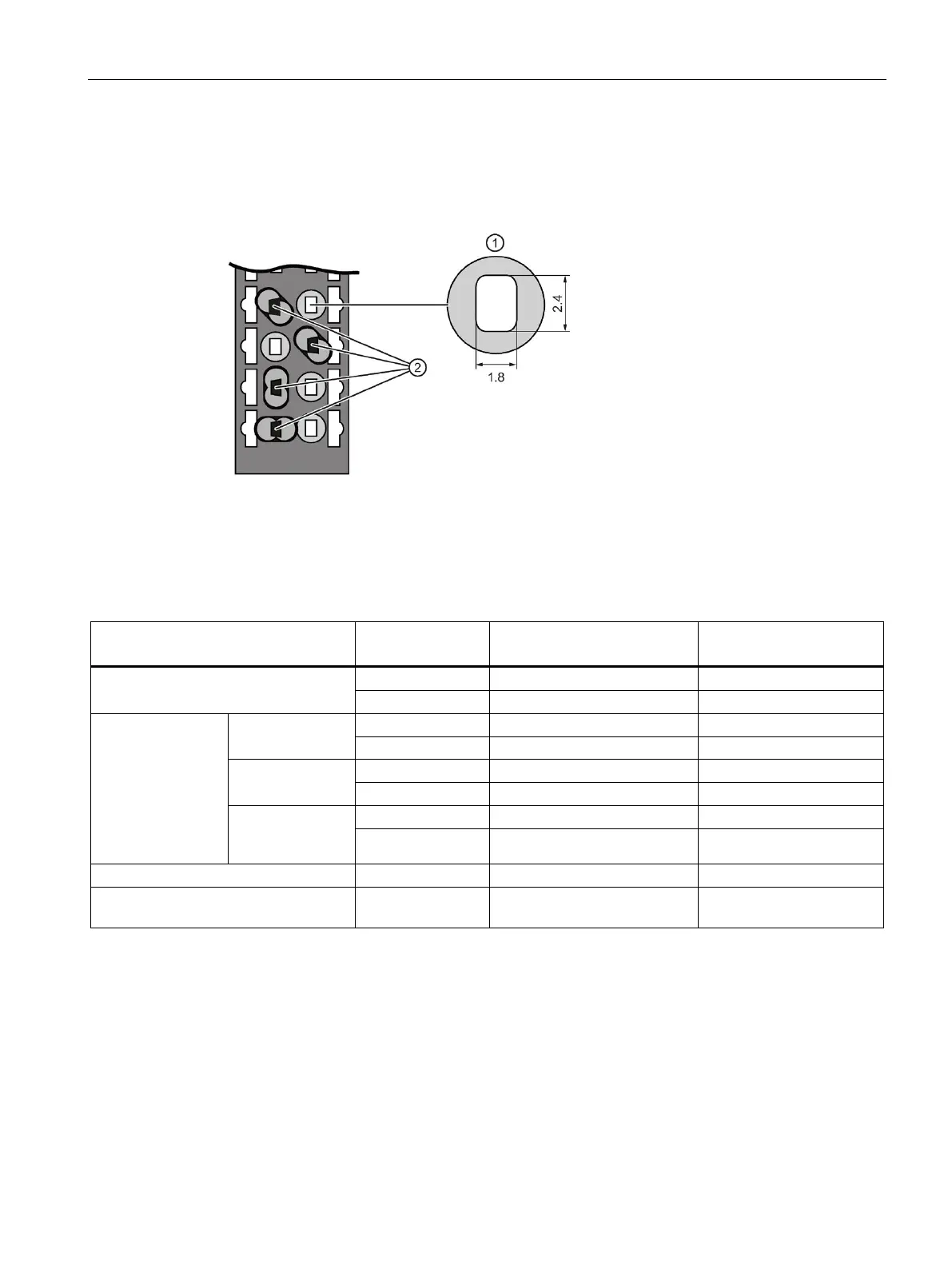

TWIN end sleeves for the cables of the I/O modules' push-in terminals

Due to the space required by TWIN end sleeves with 0.75 mm

2

cross-section, you must

ensure a correct angle for the cable arrangement when crimping the TWIN end sleeve so

that the cables are optimally arranged.

Cross-section of the terminal compartment

Crimping TWIN end sleeves at the correct angle

Figure 6-4 TWIN end sleeves

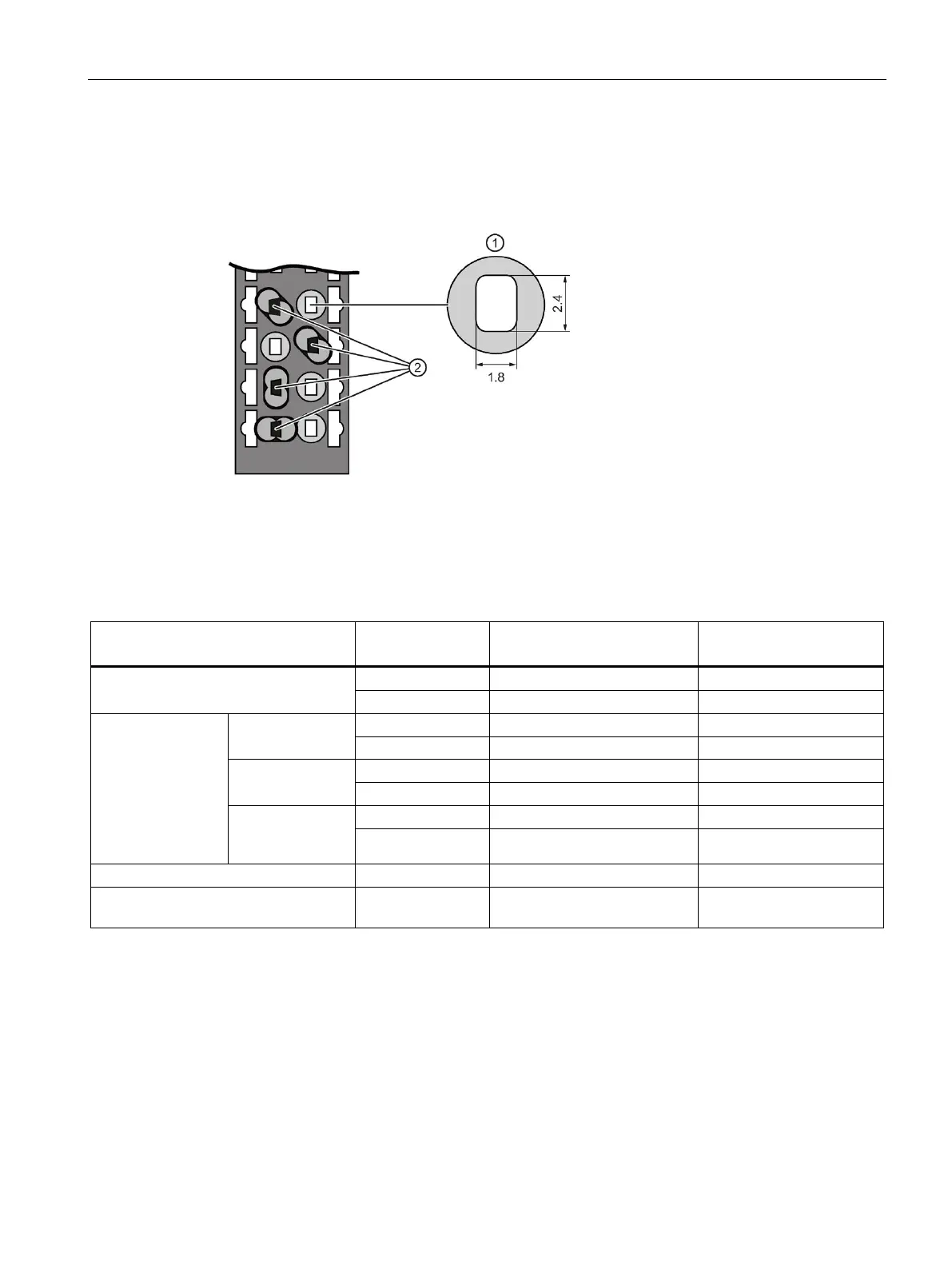

Wiring rules for motor starters

T1, T2, T3, PE, 24 V DC, F-DI,

M

DI1 ... DI3, LC, M, 24 V

OUT

Permitted cable cross-sections of solid

cables (Cu)

2

2

2

Permitted cable

cross-sections of

flexible cables (Cu)

Without end

sleeve

2

2

2

With end sleeve

2

2

2

AWG: 18 to 10 AWG: 20 to 12 AWG: 24 to 16

With end sleeve

(with plastic

2

2

2

AWG: 18 to 11 AWG: 20 to 16 AWG: 24 to 18

Stripping length of the wires

End sleeves according to DIN 46228

15 mm long 10 mm long 8 mm long

Safety standards for fail-safe motor starters

Fail-safe motor starters fulfill the following standards under certain conditions:

● PL e/Cat. 4 according to EN ISO 13849-1

● Safety Integrity Level SILCL3 acc. to IEC 62061

To fulfill both standards, lay cross-circuit proof and P-cross-circuit proof control cables from

the safe output of a sensor or F-DQ to the safe input of the motor starter, e.g. as a

separately sheathed cable or in a separate cable duct.

Loading...

Loading...