Configuration

4.22 Data points

TIM 1531 IRC

Operating Instructions, 02/2018, C79000-G8976-C468-02

125

Set limit value 'low' / Set limit value 'high'

Requirements for the function

● Configuration of the threshold trigger for this data point

● PLC tag in the bit memory operand area or data area

The analog value data point must be linked to a PLC tag in the bit memory or data area

(data block).

For PLC tags for analog input modules (input operand area) limit value configuration is

not possible. With these analog values the limit values of the following table are used

automatically.

The configuration of limit values is pointless for measured values that have already been

preprocessed on the CPU.

In these two input boxes, you can set a limit value in the direction of the start of the

measuring range or in the direction of the end of the measuring range. You can also

evaluate the limit values, for example as the start or end of the measuring range.

Configuration of the limit value

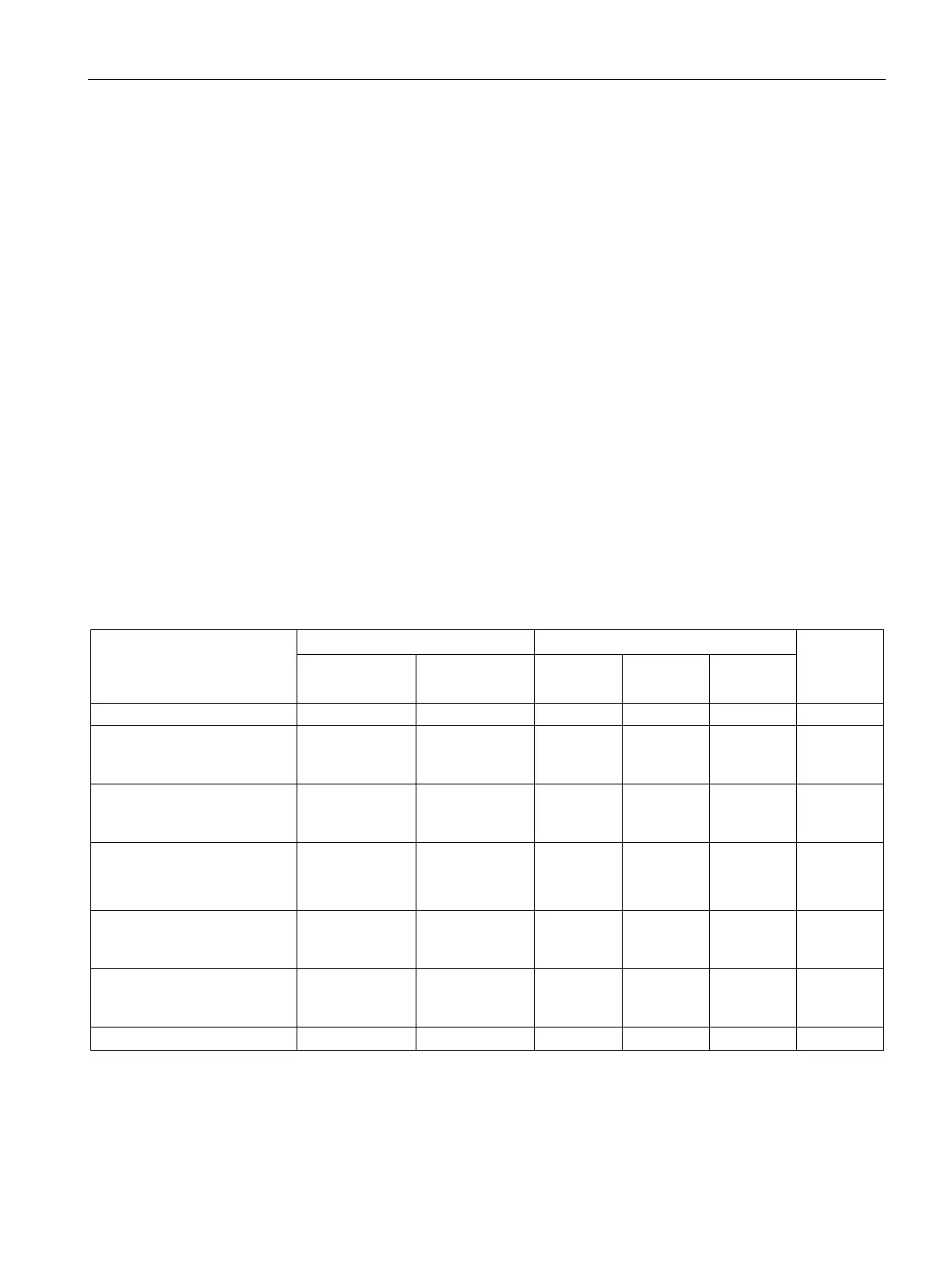

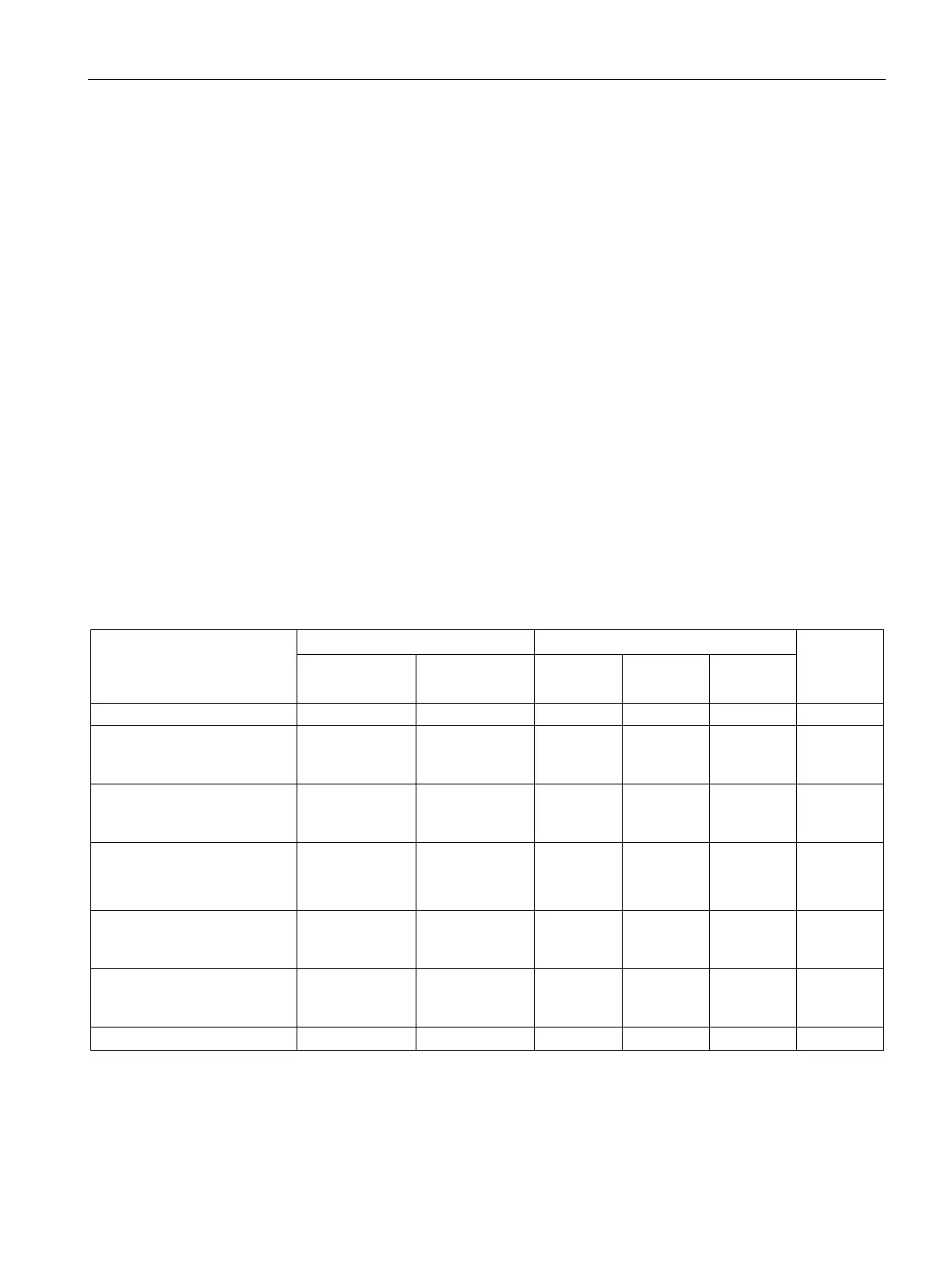

The limit value is configured as a whole decimal number. The range of values is based on

the range of values of the raw value of analog input modules.

Raw value (16 bits) of the PLC tag

Overrange 32511

...

7EFF

...

23.515

...

23.515

...

22.810

...

117.593

...

Nominal range

(unipolar / life zero)

27648

...

6C00

...

20

...

20

...

100

...

Nominal range (bipolar) 27648 ...

0

6C00 ...

0000

20 ...

0

100 ...

0

Underrange

(unipolar / life zero)

-1

...

FFFF

...

-0.001

...

3.999

...

-0.004

...

Underrange (bipolar) -27649

...

93FF

...

-20.001

...

-100.004

...

Please note: The entry of the value 0 (zero) is interpreted as a deactivated limit value.

Loading...

Loading...