Instruction Manual for AS380 Series Elevator Integrated Drive Controller

Chapter 8 Elevator Elevator Commissioning Guide

When zero servo ends, AIO inverter gives the controller a signal with speed instruction, and

the elevator begins to accelerate.

F212, F213 and F214 are proportional (P0), integral constant (I0) and the differential constant (D0) of the

zero servo regulator. In adjustment, fist set P0 to a very small value, and have the elevator go downward

non-loaded; at this moment, the elevator shows pull-back at start. Increase the P0 value gradually, until the elevator

stops showing pull-back at start. However, if P0 is too large, the elevator may oscillate up and down at start. So in

case of obvious oscillation at start, decrease the P0 value. I0 is the integral constant of zero-speed PID regulator at

stop. The greater I0 is, the shorter the response time is. If the I0 value is too small, P0 will not have enough time to

motion; if I0 is too large, high frequency oscillation may be easily produced. D0 helps the system with the

response speed. The larger D0 is, the faster response is; but too large D0 can cause oscillation.

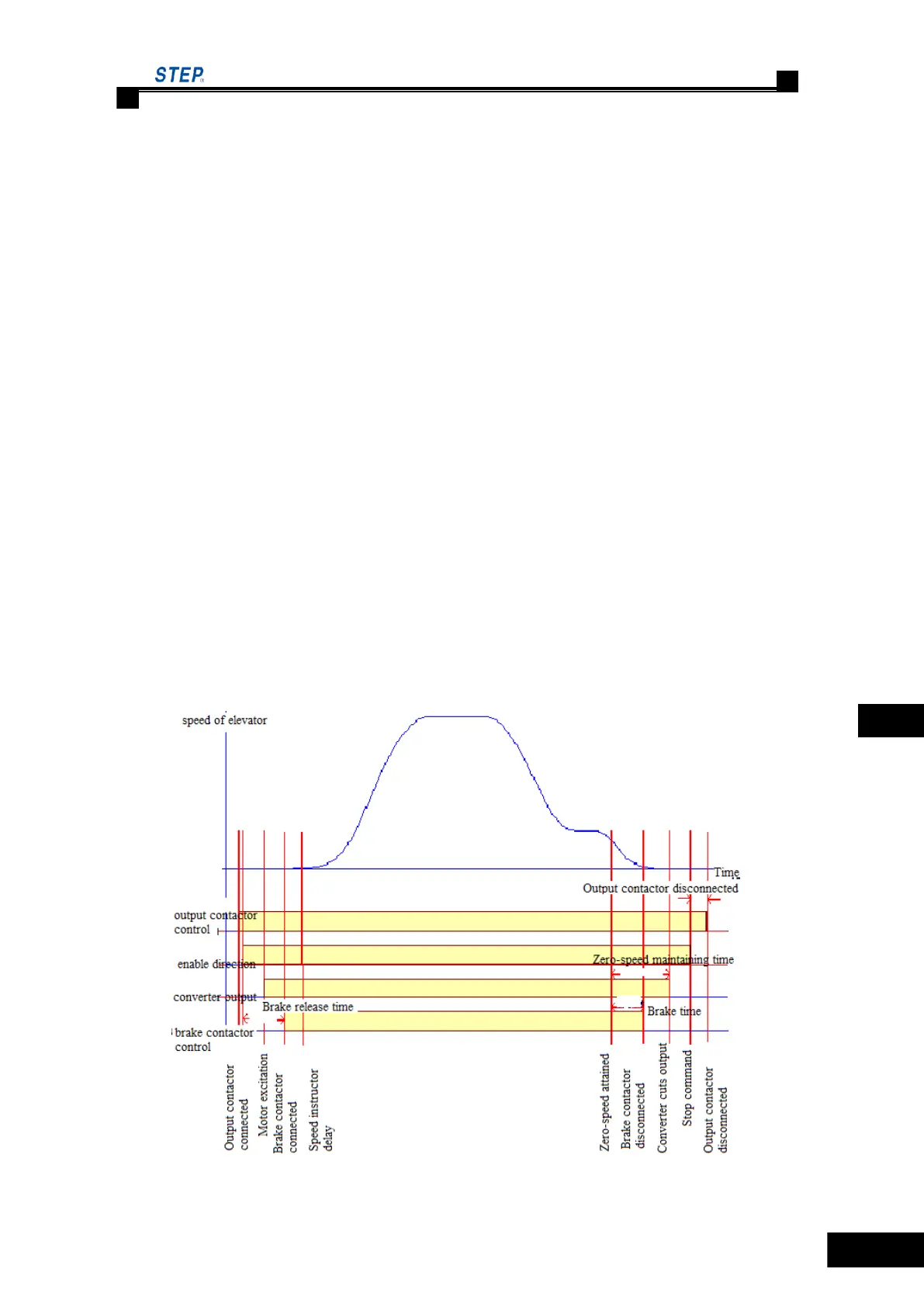

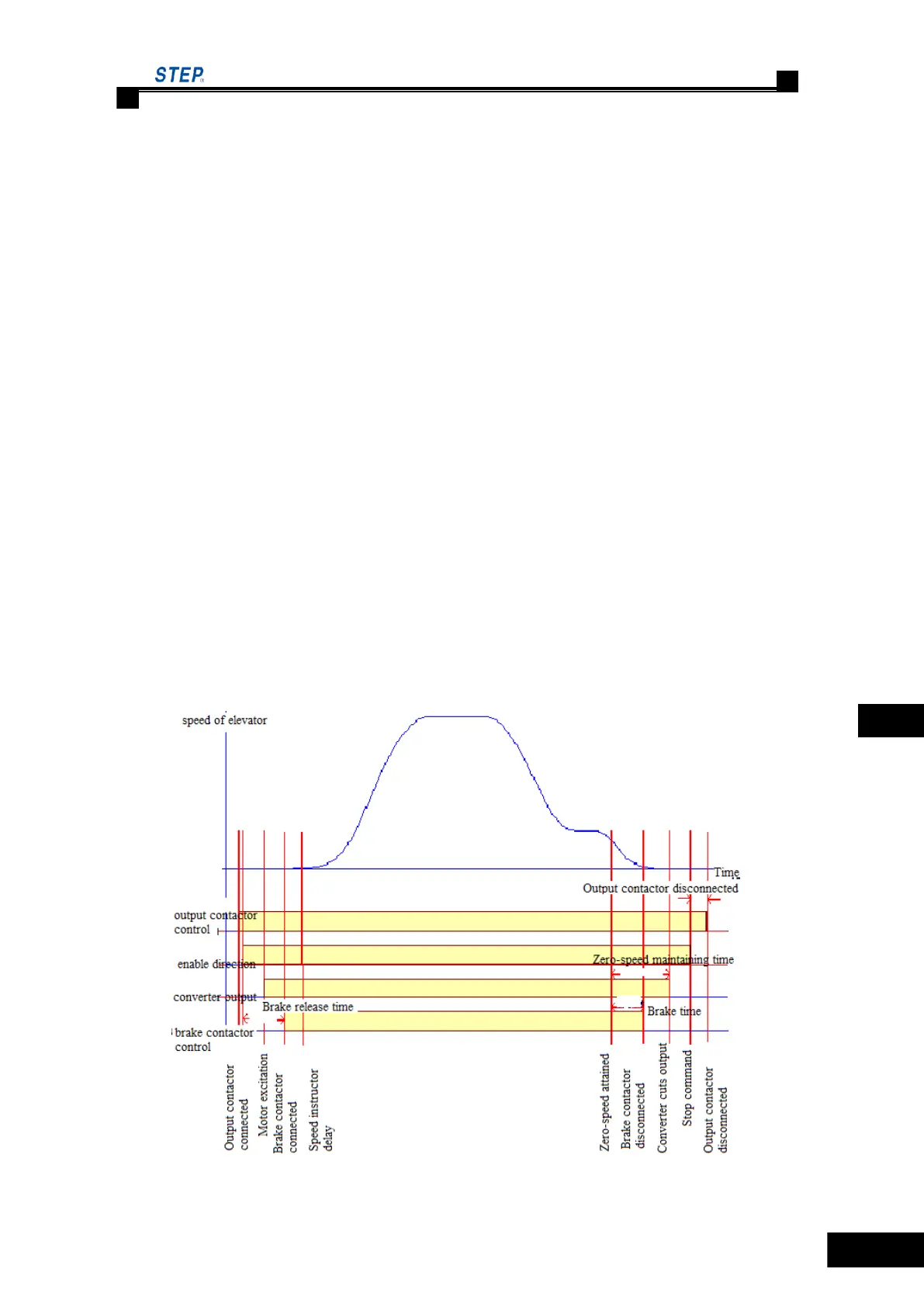

(b) Adjust timing sequence to improve starting comfort

The starting timing sequence is the coordination between the main contactor pull, the release

of inverter upward or downward command (or enable signal), brake open and the speed signal,

when the elevator starts. In general, at the elevator starter, the main contactor pulls first, then

inverter enable signal releases, and then the brake open and the speed reference command give out.

The order between the speed reference and the brake has a great impact on the starting comfort of

the elevator. The ideal coordination point is: at the mechanical movement (really open) of the

brake, the speed reference is given. However, due to the brake contactor delay and the mechanical

brake delay, it is not easy to give accurate data for the two motions to achieve the desired effect.

The following principles may be observed for adjusting timing sequence: in no-load operation, if

the downward start shows an obvious pull back, postpone the opening time of the brake (or set the

reference speed earlier; if the downward start shows a weak pull back, but an obvious push for the

upward start, set the brake o timing diagram at start and stop.

Fig 8.2 Adjustable Timing Sequence Diagram

Loading...

Loading...