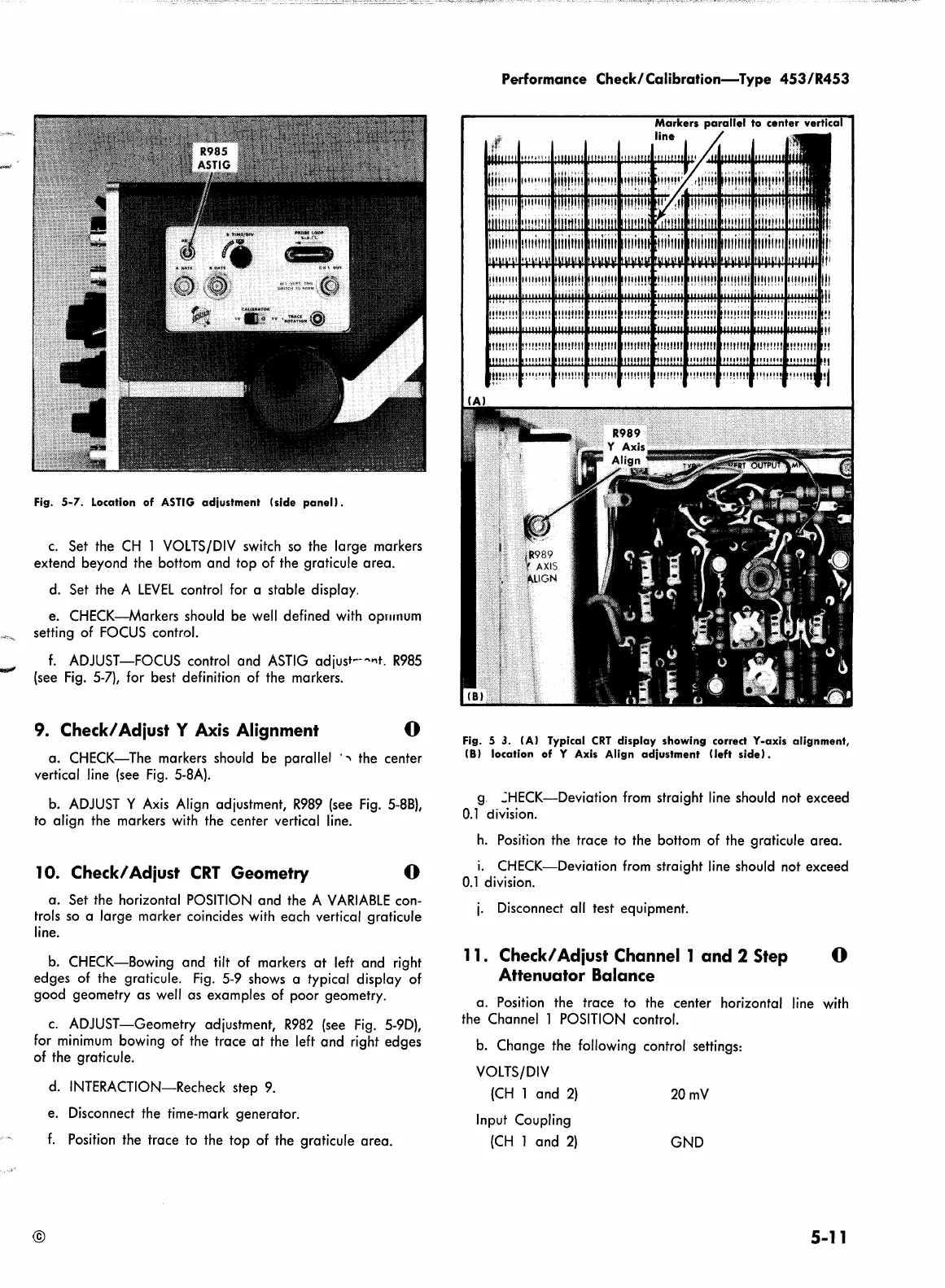

Fig.

5-7.

Location

of

ASTIG

adjustment

(side

panell.

c.

Set the

CH

1

VOLTS/DIV

switch

so

the large markers

extend beyond the bottom and top of the graticule area.

d.

Set the A

LEVEL

control for a stable display.

e. CHECK-Markers should be

well

defined

with

oprunum

setting of

FOCUS

control.

f.

ADJUST-FOCUS control and

ASTIG

adjust-

...

,,t.

R985

(see

Fig.

5-7),

for best definition

of

the markers.

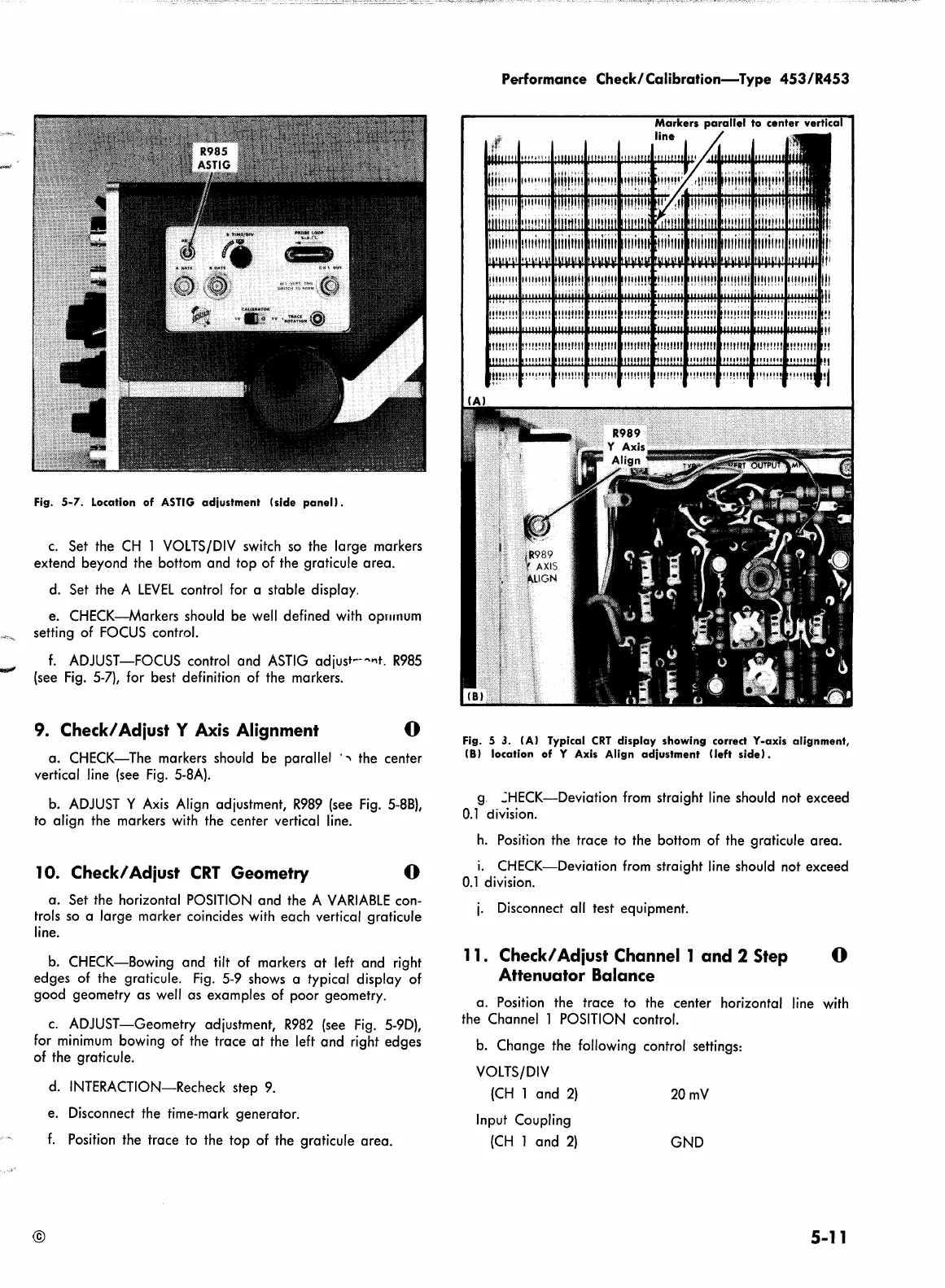

9. Check/ Adiust Y Axis Alignment

0

a. CHECK-The markers should be parallel ·

~

the center

vertical

line

(see

Fig.

5-8A).

b.

ADJUST

Y

Axis

Align

adjustment,

R989

(see

Fig.

5-8B),

to

align the markers

with

the center vertical

line.

10. Check/ Adiust

CRT

Geometry

0

a. Set the horizontal

POSITION

and the A

VARIABLE

con-

trols so a large marker coincides

with

each vertical graticule

line.

b.

CHECK-Bowing and tilt of markers

at

left and right

edges

of

the graticule.

Fig.

5-9

shows a typical display of

good geometry as

well

as examples of poor geometry.

c.

ADJUST-Geometry adjustment,

R982

(see

Fig.

5-9D),

for

minimum

bowing of the trace

at

the left and right edges

of

the graticule.

d.

INTERACTION-Recheck step

9.

e. Disconnect the time-mark generator.

f.

Position the trace to the top of the graticule area.

©

Performance

Check/Calibration-Type

453/R453

Markers

parallel

to

center

vertica

line

Fig. 5

3. IAI Typical

CRT

display

showing correct Y-axis

alignment,

(Bl location of Y Axis Align

adjustment

!left

side).

g.

.:HECK-Deviation

from

straight

line

should not exceed

0.1

division.

h.

Position the trace to the bottom of the graticule area.

i.

CHECK-Deviation

from

straight

line

should not exceed

0.1

division.

j.

Disconnect all test equipment.

11

. Check/ Adiust Channel 1

and

2 Step 0

Attenuator Balance

a. Position the trace to the center horizontal

line

with

the Channel 1

POSITION

control.

b.

Change the following control settings:

VOLTS/DIV

(CH

1 and

2)

Input Coupling

(CH

l and

2)

20mV

GND

5-11

Loading...

Loading...