m.

Position

the bottom of the display to the bottom

hori-

zontal

line.

n.

CHECK-Compression or expansion 0.15 division or

less

(see

Fig.

5-15).

o.

Disconnect all test equipment.

20.

Check Trace Shift Due

to

Input Gate Current

a. Change the following control settings:

VOLTS/DIV

(CH

l and

2)

5mV

VARIABLE

(CH

l and

2)

CAL

Input Coupling

(CH

l and

2)

GND

LEVEL

Clockwise

b.

Position the trace

to

the center horizontal

line

with

the Channel 2

POSITION

control.

c.

CHECK-Set the Channel 2 Input Coupling

switch

to

DC.

Trace shift should be negligible.

d.

Set the

MODE

switch to

CH

1.

e.

Position

the trace

to

the center horizontal

line

with

the Channel l

POSITION

control.

f.

CHECK-Set the Channel l

Input

Coupling switch to

DC.

Trace shift should be negligible.

21

. Check Alternate Operation

a. Set the

MODE

switch

to

ALT.

b.

Position

the traces about two divisions apart.

c.

Turn

the A

TIME/DIV

switch

throughout

its

range.

d.

CHECK-Trace alternation between Channel l and 2

at

all sweep rates.

At

faster sweep rates, alternation

is

not

apparent; instead display appears as two traces

on

the

screen.

22.

Check/ Adiust Channel 1 and 2

Volts/

Division Switch

Series

Compensation

a. Change the following control settings:

VOLTS/DIV

(CH

l and

2)

Input Coupling

(CH

l and

2)

MODE

A and B

TIME/DIV

20mV

DC

CH

1

.2

ms

0

b.

Connect the square-wave generator

(Type

l

06)

high-

amplitude output connector to the Channel l

INPUT

con-

"""

nector through the five-nanosecond

GR

cable, 5 X

GR

attenu-

ator and

50-ohm

in-line

termination

in

given order.

©

Performance Check/Calibration-Type

453/R453

c.

Set the square-wave generator for four divisions of one-

kilohertz signal.

d. Set the A

LEVEL

control for a stable display.

e. CHECK-CRT display

at

each

CH

1

VOLTS/DIV

switch

setting listed

in

Table

5-2

for optimum square corner

(see

Fig.

5-16A,

B,

and

C).

f.

ADJUST-CH l

VOLTS/DIV

switch

series compensation

as given

in

Table

5-2

for optimum square corner

on

the dis-

play. Readjust the generator output

with

each setting of the

CH

l

VOLTS/DIV

switch (remove 5 X attenuator as required)

to provide four divisions of deflection.

Fig.

5-l

6D

shows the

location

of

the variable capacitors.

g. Disconnect the signal

from

the Channel 1

INPUT

con-

nector and reconnect

it

to the Channel 2

INPUT

connector

through the five-nanosecond

GR

cable, 5 X

GR

attenuator

and

50-ohm

in-line termination.

h.

Set the

MODE

switch to

CH

2.

i.

CHECK-CRT display

at

each

CH

2

VOL

TS/DIV

switch

setting listed

in

Table

5-2

for

optimum square corner

(see

Fig.

5-16A,

B,

and

C).

Remove

5X

attenuator as required.

j.

ADJUST-CH 2

VOLTS/DIV

switch

series compensation

as given

in

Table

5-2

for optimum square corner

on

the

dis-

play. Readjust the generator output

with

each setting of the

CH

2

VOLTS/DIV

switch

(remove 5 X attenuator as required)

to provide four divisions of deflection.

Fig.

5-l

6D

shows the

location of the variable capacitors.

k.

Disconnect the test equipment

from

the Channel 2

INPUT

connector.

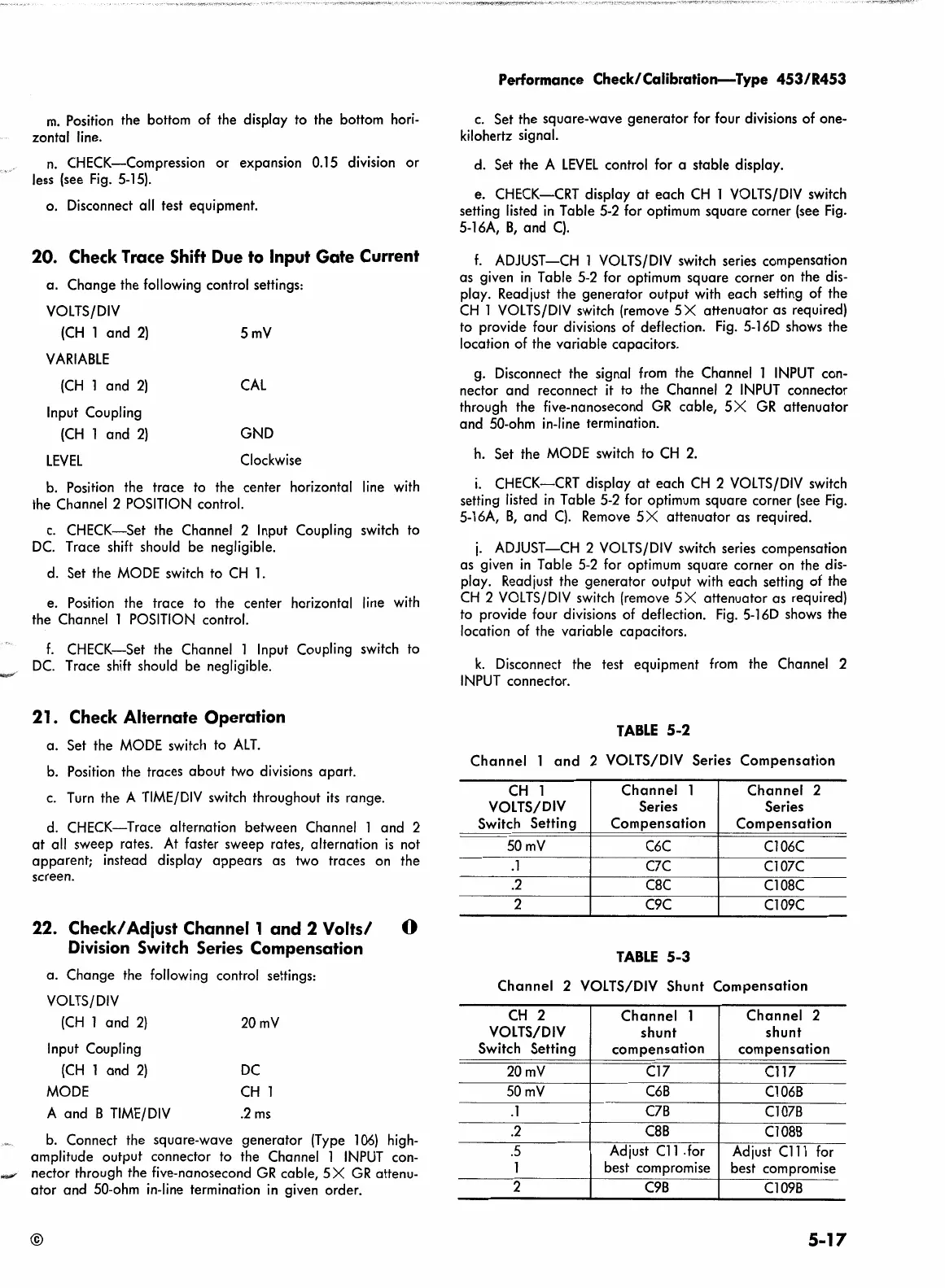

TABLE

5-2

Channel l

and

2 VOLTS/DIV Series Compensation

CH

l

Channel l Channel

2

VOLTS/DIV

Series Series

Switch Setting

Compensation Compensation

SOmV

C6C

Cl06C

. l

C7C

Cl07C

.2

CBC

Cl08C

2

C9C

Cl09C

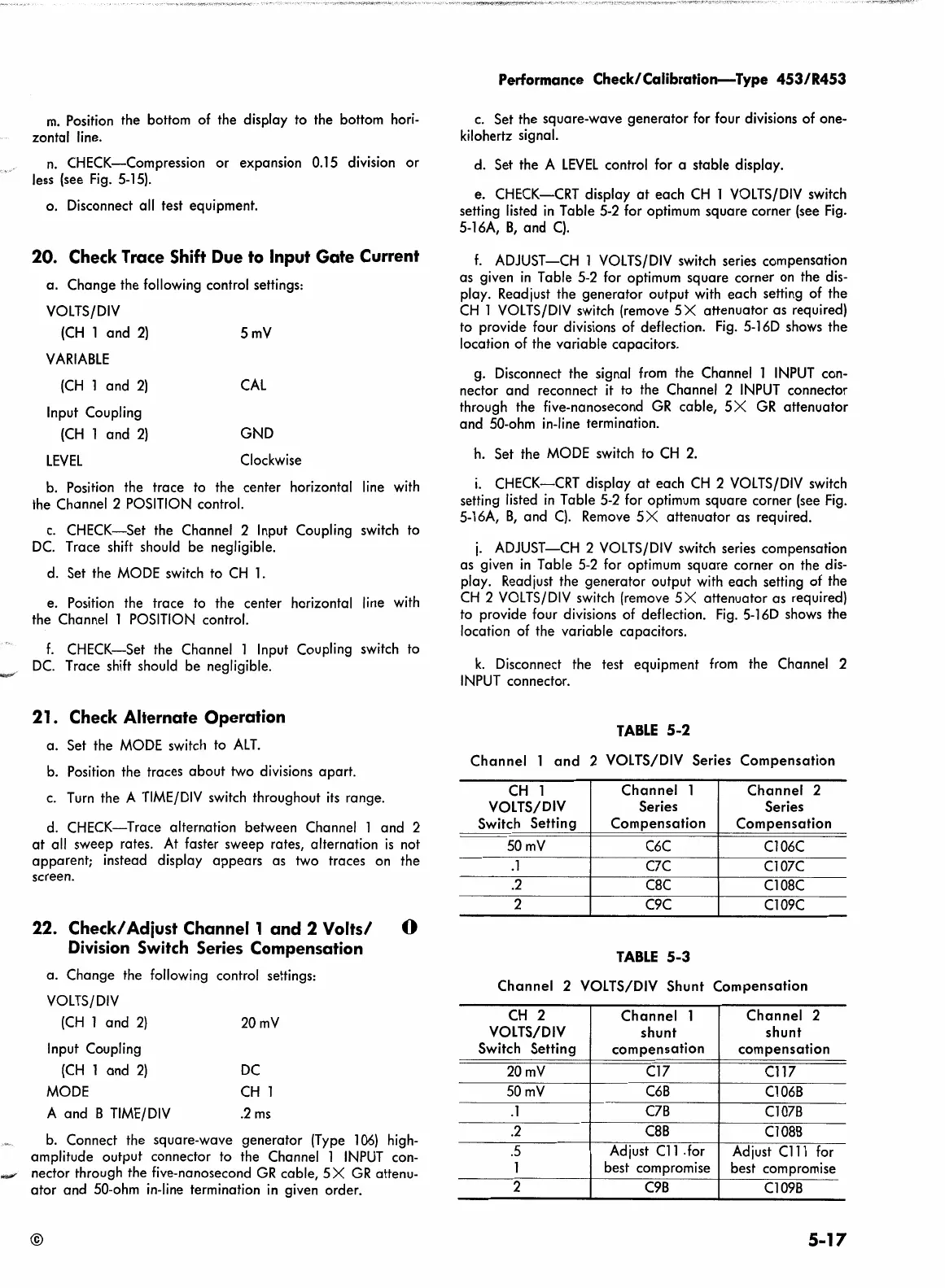

TABLE

5-3

Channel 2 VOLTS/DIV Shunt Compensation

CH

2

Channel 1 Channel 2

VOLTS/DIV shunt

shunt

Switch Setting

compensation

compensation

20mV

Cl7

Cl

17

50mV

C6B

Cl06B

. l

C7B

Cl07B

.2

CBB

ClOBB

.5

Adjust

Cll

.for

Adjust

Cl

11

for

l

best compromise

best compromise

2

C9B

Cl09B

5-17

Loading...

Loading...