Performance

Check/Calibration-Type

453/R453

•

•

!

__

•

'·'

·l

I~

I

'

' '

'·

~

~

'

"

--

j

~

r r

-,

, ,

,

r

··r

r

r

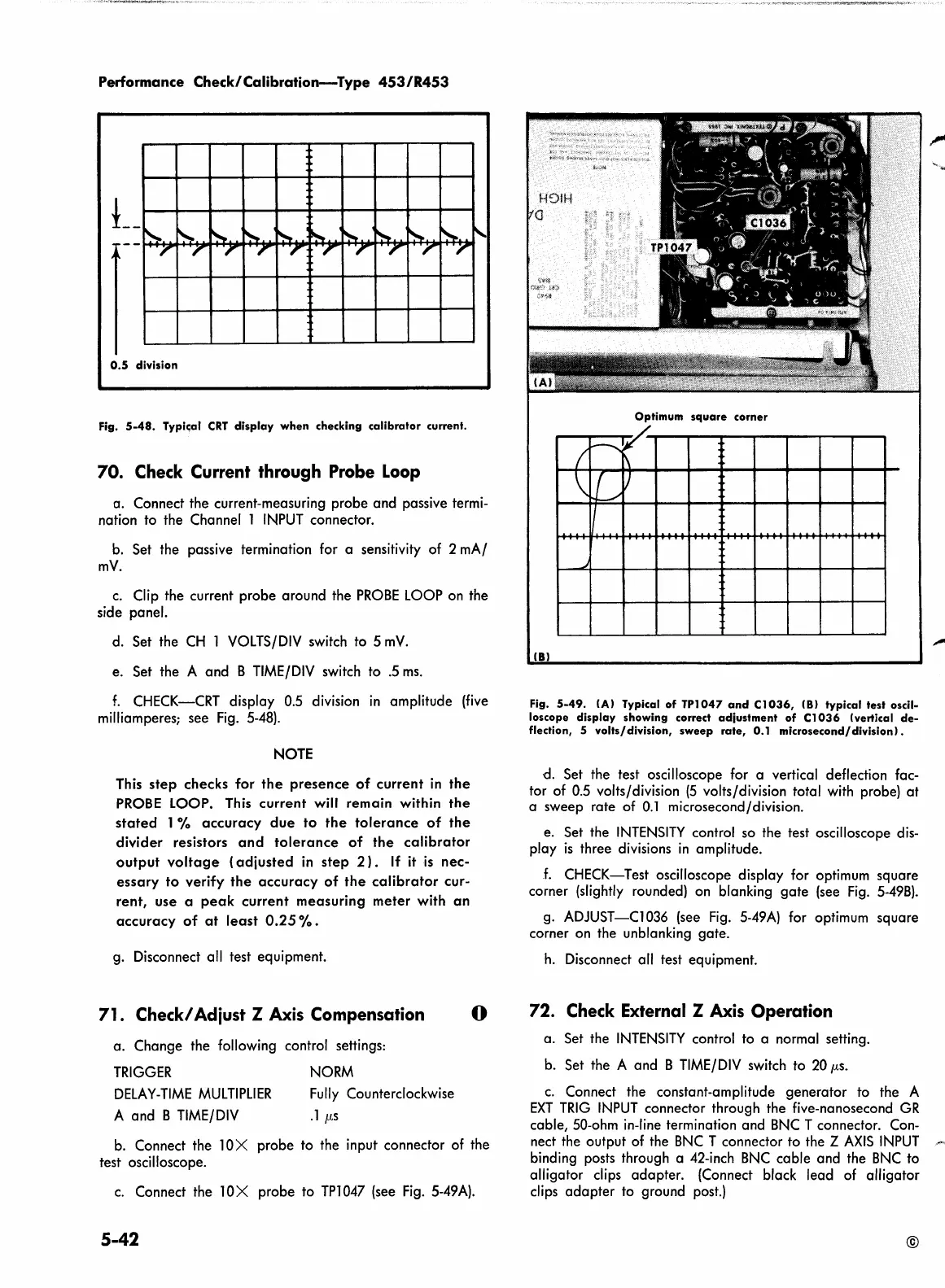

0.5

division

Fig.

5-48.

Typic;al

CRT

display

when

checking

calibrator

current.

70. Check Current through Probe

Loop

a.

Connect

the

current-measuring

probe

and

passive termi-

nation to

the

Channel l INPUT connector.

b. Set

the

passive termination for a sensitivity

of

2

mA/

mV.

c. Clip

the

current

probe

around

the

PROBE

LOOP on

the

side

panel.

d. Set

the

CH

l VOLTS/DIV switch

to

5

mV.

e. Set

the

A

and

B TIME/DIV switch

to

.5

ms.

f.

CHECK-CRT

display 0.5 division m

amplitude

(five

milliamperes;

see

Fig. 5-48).

NOTE

This

step

checks

for

the

presence

of

current

in

the

PROBE LOOP. This

current

will

remain

within

the

stated

l %

accuracy

due

to

the

tolerance

of

the

divider

resistors

and

tolerance

of

the

calibrator

output

voltage

(adjusted

in

step

2).

If it

is

nec-

essary

to

verify

the

accuracy

of

the

calibrator

cur-

rent,

use

a

peak

current

measuring

meter

with

an

accuracy

of

at

least

0.25

% .

g. Disconnect all test equipment.

71. Check/ Adiust Z Axis Compensation

a.

Change

the

following control settings:

TRIGGER

DELAY-TIME

MULTIPLIER

A

and

B TIME/DIV

NORM

Fully Counterclockwise

.l µs

0

b. Connect the l 0 X

probe

to

the input connector of the

test oscilloscope.

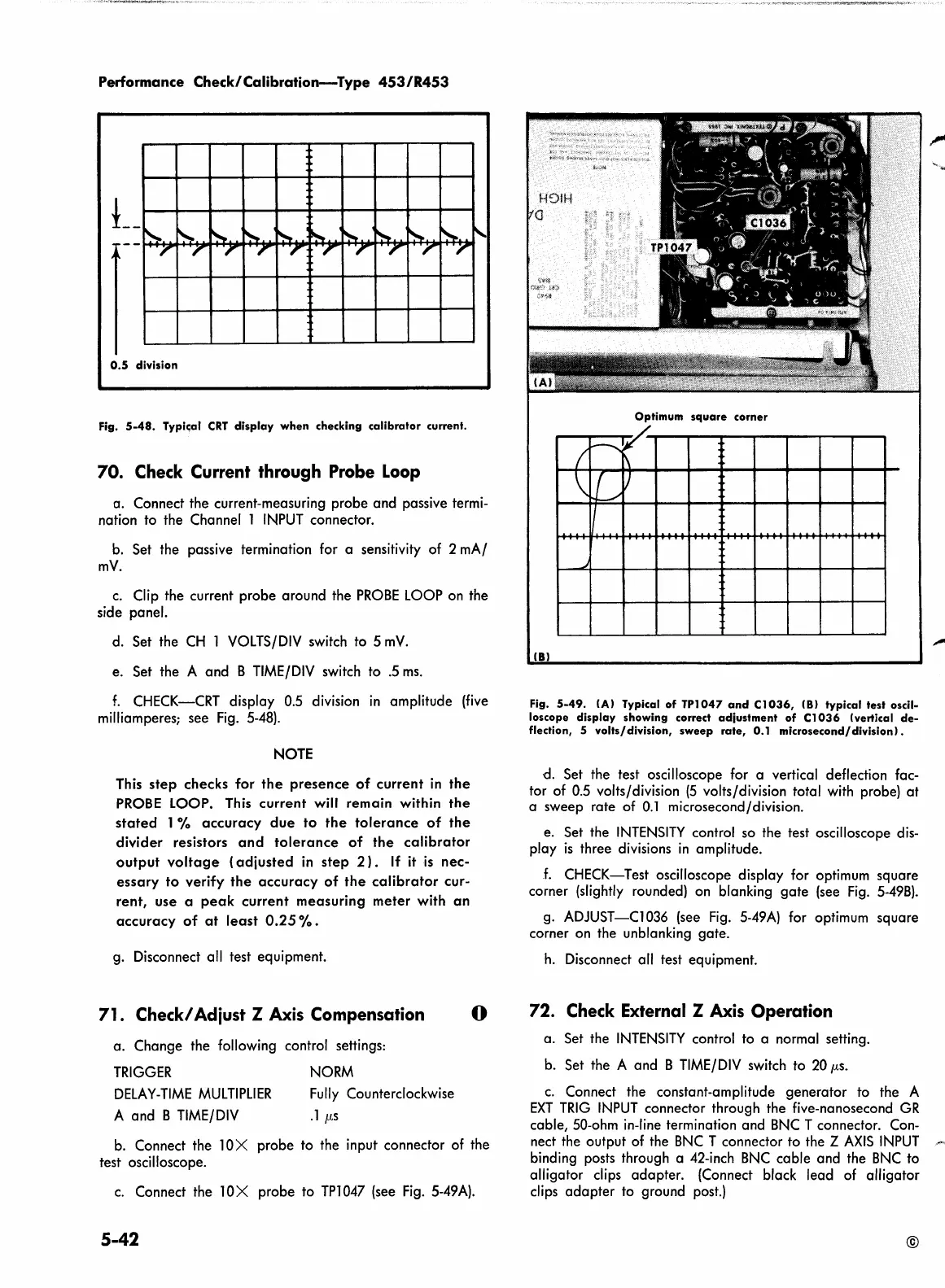

c. Connect

the

l 0 X

probe

to TPl 047 (see Fig. 5-49A).

5-42

Optimum

square

corner

(

--.....'

I?

\

\

J

_/)

I

.

.

~

(BJ

Fig.

5-49.

IA) Typical

of

TPl

047

and

Cl

036,

IBJ

typical

test

oscil-

loscope

display

showing correct

adjustment

of

Cl

036

(vertical

de-

flection, 5

volts/division,

sweep

rate,

0.1

microsecond/division).

d.

Set

the

test oscilloscope for a vertical deflection fac-

tor

of 0.5 volts/division

(5

volts/division total with probe)

at

a

sweep

rate

of

0.1

microsecond/division.

e. Set the

INTENSITY

control so

the

test oscilloscope dis-

play

is

three

divisions

in

amplitude.

.f.

CHECK-Test

oscilloscope

display

for optimum

square

corner (slightly rounded) on blanking

gate

(see Fig. 5-498).

g.

ADJUST-Cl036

(see Fig. 5-49A) for optimum

square

corner on the unblanking

gate.

h.

Disconnect all test equipment.

72. Check External Z Axis Operation

a.

Set the

INTENSITY

control to a normal setting.

b. Set

the

A

and

B TIME/DIV switch

to

20

µs.

c.

Connect

the

constant-amplitude

generator

to

the

A

EXT

TRIG

INPUT

connector through

the

five-nanosecond

GR

cable,

50-ohm in-line termination

and

BNC T connector. Con-

nect the

output

of the

BNC

T connector

to

the

Z

AXIS

INPUT

binding posts through a 42-inch BNC

cable

and

the BNC

to

alligator

clips

adapter.

(Connect black

lead

of

alligator

clips

adapter

to ground post.)

©

Loading...

Loading...