Maintenance-Type

453/R453

Interior. Dust

in

the interior of the instrument should be

removed occasionally due to

its

electrical conductivity under

high-humidity conditions.

The

best way to clean the interior

it

to blow off the accumulated dust with dry, low-velocity

air.

Remove

any dirt which remains with a soft paint brush

or a cloth dampened with a

mild

detergent and water solu-

tion. A cotton-tipped applicator

is

useful

for cleaning

in

narrow spaces or for cleaning ceramic terminal strips and

circuit boards.

The

high-voltage circuits, particularly parts located

in

the high-voltage compartment and the area surrounding the

post - deflection

anode

connedor, should receive special

attention. Excessive dirt

in

these areas may cause high-

voltage arcing and result

in

improper instrument operation.

Lubrication

General.

The

reHability of potentiometers, rotary switches

and other moving parts can be maintained

if

they

are

kept

properly lubricated.

Use

a cleaning-type lubricant (e.g.,

Tektronix Part No. 006-0218-00) on switch contacts.

Lubri-

cate switch detents with a heavier grease (e.g., Tektronix

Part No. 006-0219-00). Potentiometers which are not per-

manently sealed should be lubricated

with

a lubricant which

does not affect electrical characteristics (e.g., Tektronix Part

No. 006-0220-00).

The

pot lubricant can also be used on

shaft bushings.

Do

not over-lubricate. A lubrication

kit

con-

taining the necessary lubricants and instructions

is

available

from

Tektronix,

Inc.

Order Tektronix Part No. 003-0342-00.

Fan.

The

fan-motor bearings

are

sealed and do not

re-

quire lubrication.

Visual Inspection

The

Type

453

should be inspected occasionally for such

defects as broken connections, broken or damaged ceramic

strips, improperly seated transistors, damaged circuit boards

and heat-damaged parts.

The

corrective procedure for most visible defects

is

obvi-

ous; however, particular care

must

be taken

if

he·at-damaged

components

are

found. Overheating usually indicates other

trouble

in

the instrument; therefore,

it

is

important that the

cause of over-heating be corrected to prevent recurrence of

the damage.

Transistor Checks

Periodic checks of the transistors

in

the Type

453

are

not

recommended.

The

best check of transistor performance

is

its

actual operation

in

the instrument. More details

on

check-

ing

transistor operation

is

given under Troubleshooting.

Recalibration

To

assure accurate measurements, check the calibration of

this

instrument after each 1000 hours of operation or every

six

months

if

used infrequently.

In

addition, replacement of

components may necessitate recalibration of the affected

circuits. Complete calibration instructions

are

given

in

the

Calibration section.

The

calibration procedure can also be helpful

in

localiz-

ing cerain troubles

in

the instrument.

In

some cases, minor

4-2

troubles may be revealed

and/

or corrected by recalibra-

tion.

TROUBLESHOOTING

Introduction

The

following information

is

provided to facilitate trouble-

shooting of the Type 453. Information contained

in

other

sections of

this

manual should be used along with the

fol-

lowing information to aid

in

locating the defective compon-

ent.

An

understanding of the circuit operation

is

very help-

ful

in

locating troubles. See the Circuit Description section

for complete information.

Troubleshooting Aids

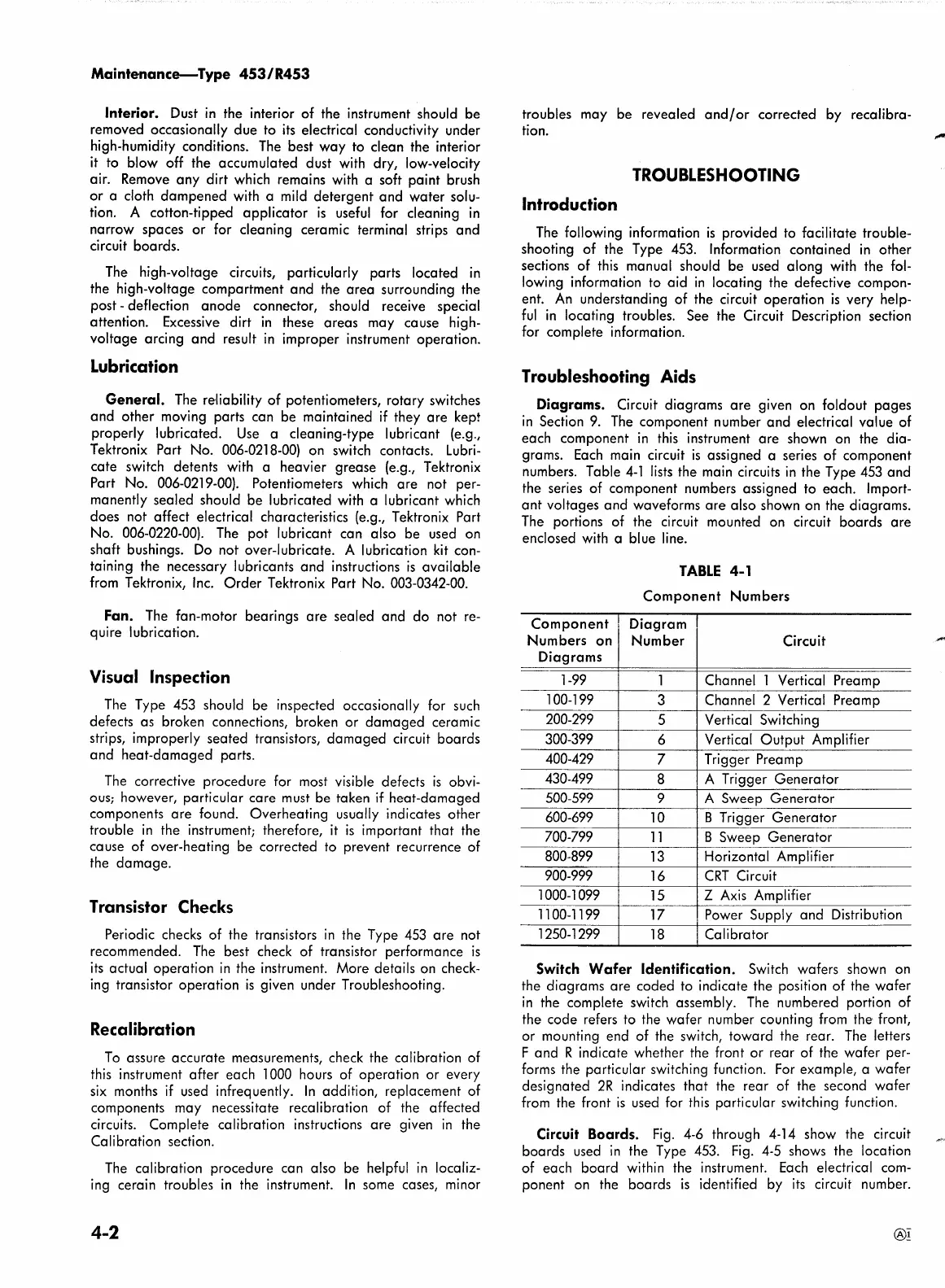

Diagrams. Circuit diagrams

are

given on foldout pages

in

Section

9.

The

component number and e·lectrical value of

each component

in

this

instrument are shown on the dia-

grams.

Each

main circuit

is

assigned a series of component

numbers. Table

4-1

lists

the main circuits

in

the Type

453

and

the series of component numbers assigned to each. Import-

ant

voltages and waveforms

are

also shown on the diagrams.

The

portions of the circuit mounted

on

circuit boards

are

enclosed with a blue line.

TABLE

4-1

Component

Numbers

c

omponen

D.

1agram

Numbers on

Number Circuit

Diagrams

1-99

1

Channel 1

Vertical

Preamp

100-199

3

Channel 2 Vertical Preamp

200-299

5

Vertical Switching

300-399

6

Vertical Output Amplifier

400-429

7

Trigger Preamp

430-499

8

A Trigger Generator

500-599

9

A Sweep Generator

600-699

10

B Trigger Generator

700-799

11

B Sweep Generator

800-899

13

Horizontal Amplifier

900-999

16

CRT

Circuit

1000-1099

15

Z

Axis

Amplifier

1100-1199

17

Power Supply and Distribution

1250-1299

18

Calibrator

Switch Wafer Identification. Switch wafers shown

on

the diagrams are coded to indicate the position of the wafer

in

the complete switch assembly.

The

numbered portion of

the code refers to the wafer number counting

from

the front,

or mounting end of the switch, toward the rear.

The

letters

F and R indicate whether the front or rear of the wafer per-

forms

the particular switching function.

For

example, a wafer

designated

2R

indicates that the rear of the second wafer

from

the front

is

used for

this

particular switching function.

Circuit

Boards.

Fig.

4-6 through 4-14 show the circuit

boards used

in

the Type 453.

Fig.

4-5 shows the location

of each board within the instrument.

Each

electrical

com-

ponent

on

the boards

is

identified by

its

circuit number.

Loading...

Loading...