Observe the

following

precautions when soldering to

ceramic

terminal strips.

1.

Use

a

hot

iron

for

a short time.

Apply

only

enough

he·at

to make the solder

flow

freely.

2.

Maintain

a clean,

properly

tinned tip.

3.

Avoid

putting pressure on the ceramic terminal strip.

4.

Do not

attempt

to fill the terminal-strip notch

with

solder;

use

only

enough solder to cover the wires adequately.

5.

Clean the flux from the terminal strip

with

a flux-

remover solvent.

Metal

Terminals.

When

soldering metal terminals (e.g.,

switch

terminals, potentiometers, etc),

ordinary

60/40

solder

can be used.

Use

a soldering iron with a 40- to

75-watt

rating and a

1

/

8

-inch

wide

wedge-shaped tip.

Observe the

following

precautions when soldering metal

terminals:

1.

Apply

only

enough heat to make the solder

flow

freely.

2.

Apply

only

enough solder to form a solid connection.

Excess

solder may

impair

the function

of

the part.

3.

If

a

wire

extends beyond the solder joint, clip

off

the

excess.

4.

Clean the flux from the solder joint with a flux-remover

solvent.

Component Replacement

WARNING

Disconnect

the

instrument

from

the

power

source

before

replacing

components.

Removing the Rear Panel. The rear panel must be

removed

for

access to the rear subpanel. This panel can be

removed

by

removing the Z Axis ground strap and the four

screws located near the rear feet.

Swing-Out

Chassis.

Some

of

the controls and connectors

are mounted on a swing-out

chassis

on

the

right

side

of

this

instrument.

To

reach the rear

of

this chassis

or

the com-

ponents mounted behind it, first remove the top cover from

the instrument. Then, loosen the captive securing screw

so

the chassis can swing outward.

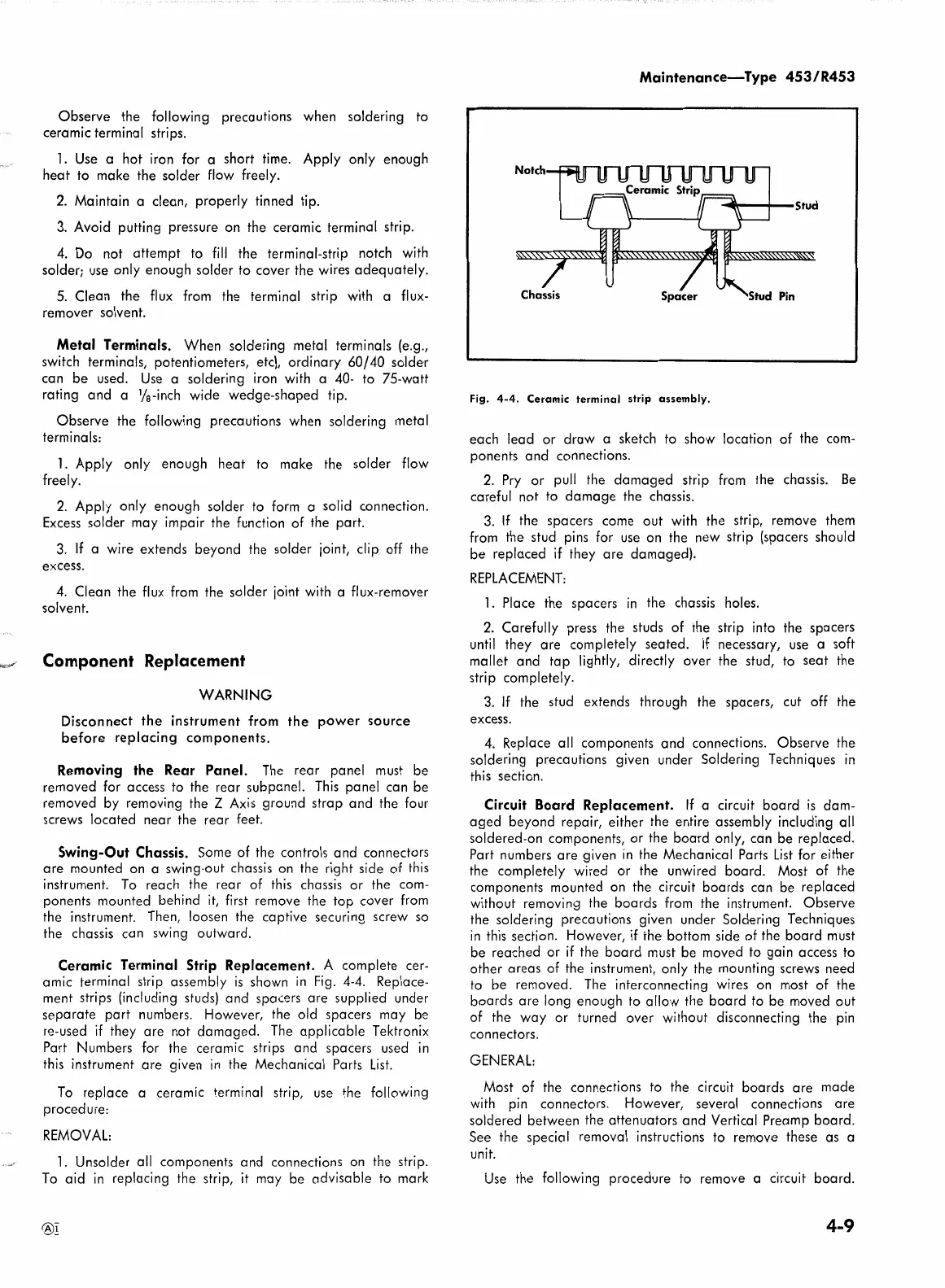

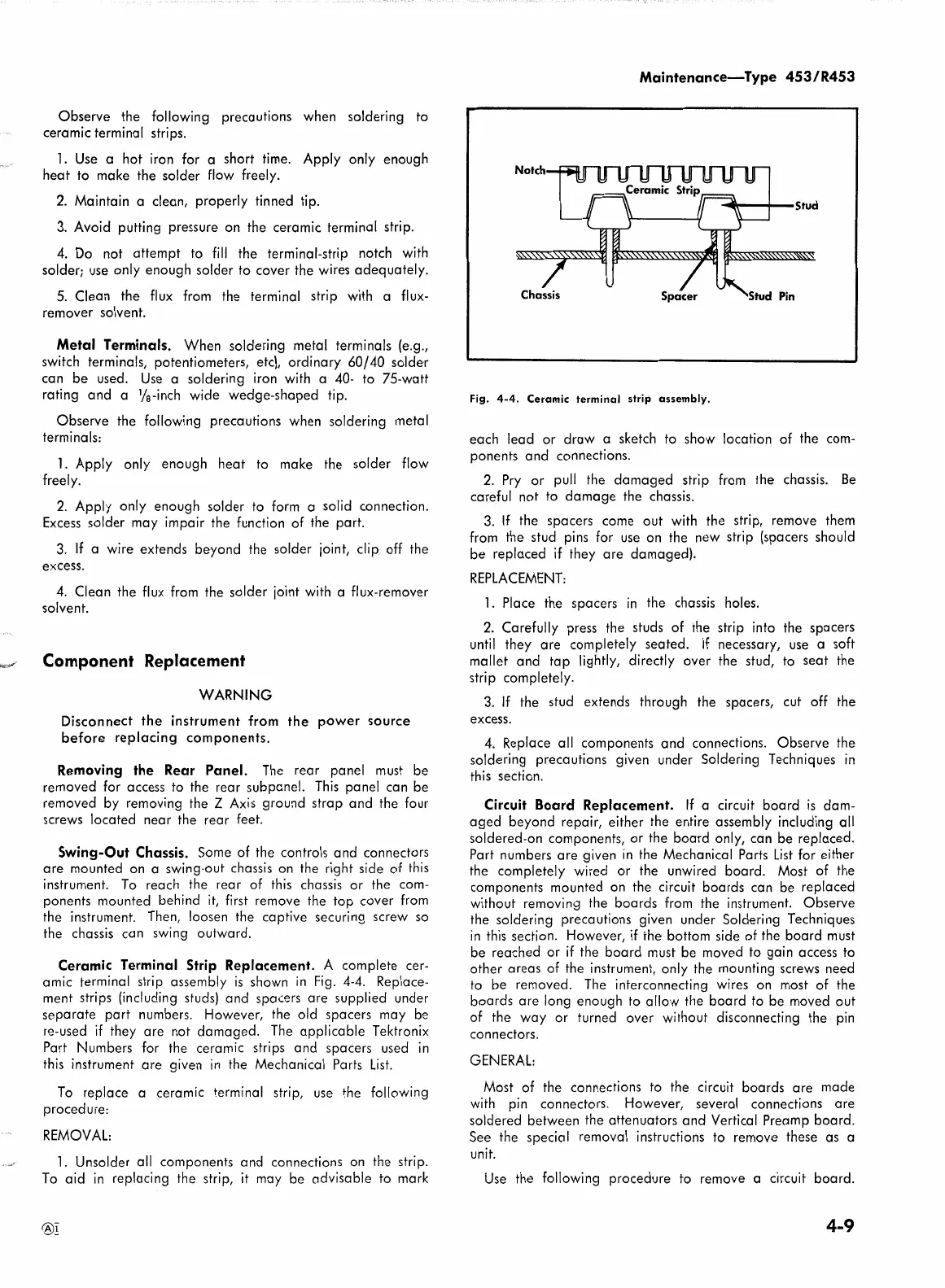

Ceramic Terminal Strip Replacement. A complete cer-

amic terminal strip assembly

is

shown in Fig. 4-4. Replace-

ment strips (including studs) and spacers are supplied under

separate

part

numbers. However, the old spacers may be

re-used

if

they are not damaged. The

applicable

Tektronix

Part Numbers

for

the ceramic strips and spacers

used

in

this instrument are given in the Mechanical

Parts

List.

To replace a ceramic terminal strip,

use

the

following

procedure:

REMOVAL:

1.

Unsolder

all

components and connections

on

the strip.

To

aid

in replacing the strip,

it

may be advisable to mark

®!

Maintenance-Type

453/R453

Fig.

4-4.

Ceramic

terminal

strip

assembly.

each lead

or

draw

a sketch to show location

of

the com-

ponents

and

connections.

2.

Pry

or

pull the

damaged

strip from the chassis.

Be

careful

not

to

damage

the

chassis.

3.

If

the spacers come

out

with

the strip, remove them

from the stud pins

for

use

on the new strip (spacers should

be replaced

if

they are damaged).

REPLACEMENT:

1.

Place the spacers in the chassis holes.

2.

Carefully

press

the studs

of

the strip into the spacers

until they are completely seated.

If

necessary,

use

a soft

mallet and

tap

lightly, directly over the stud, to seat the

strip

completely.

3.

If

the stud extends through the spacers, cut

off

the

excess.

4.

Replace

all

components and connections. Observe the

soldering precautions given under Soldering Techniques in

this section.

Circuit Board Replacement. If a circuit

board

is

dam-

aged

beyond repair, either the entire assembly including

all

soldered-on components,

or

the

board

only, can be replaced.

Part

numbers are given in the Mechanical Parts

List

for

either

the

completely

wired

or

the unwired board. Most

of

the

components mounted on the circuit boards can be replaced

without

removing the boards from the instrument. Observe

the

soldering precautions given under Soldering Techniques

in this section. However,

if

the bottom side

of

the board must

be reached

or

if

the

board

must be moved to gain access to

other areas

of

the instrument,

only

the mounting screws need

to be removed.

The

interconnecting wires on most

of

the

boards are

long enough to

allow

the

board

to be moved

out

of

the

way

or

turned over

without

disconnecting the pin

connectors.

GENERAL:

Most

of

the connections to the circuit boards are made

with pin connectors. However,

several connections are

soldered between the attenuators and Vertical Preamp

board.

See

the special removal instructions to remove these

as

a

unit.

Use

the

following

procedure to remove a circuit board.

4-9

Loading...

Loading...