Maintenance

6-4

TDS5000B Series Service Manual

If the display is very dirty, moisten the wipe with distilled water or a 75%

isopropyl alcohol solution and gently rub the display surface. Avoid using excess

force or you may damage the plastic display surface.

CAUTION. To prevent getting moisture inside the oscilloscope duri ng external

cleaning, use only enough liquid to dampen the cloth or applicator.

Inspection — Interior. To access the inside of the oscilloscope for i nspection and

cleaning, refer to the Removal and Installation Procedures in this section.

Inspect the internal portions of t he oscilloscope for damage and wear, using

Table 6--2 as a guide. Defects found shoul d be repaired immediately.

If any circuit board is repaired or replaced, check Table 6--2 in Section 5 to see if

it is necessary to adjust the oscilloscope.

CAUTION. To prevent damage from electrical arcing, ensure that circuit boards

and components are dry before applying power t o the oscilloscope.

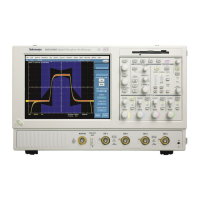

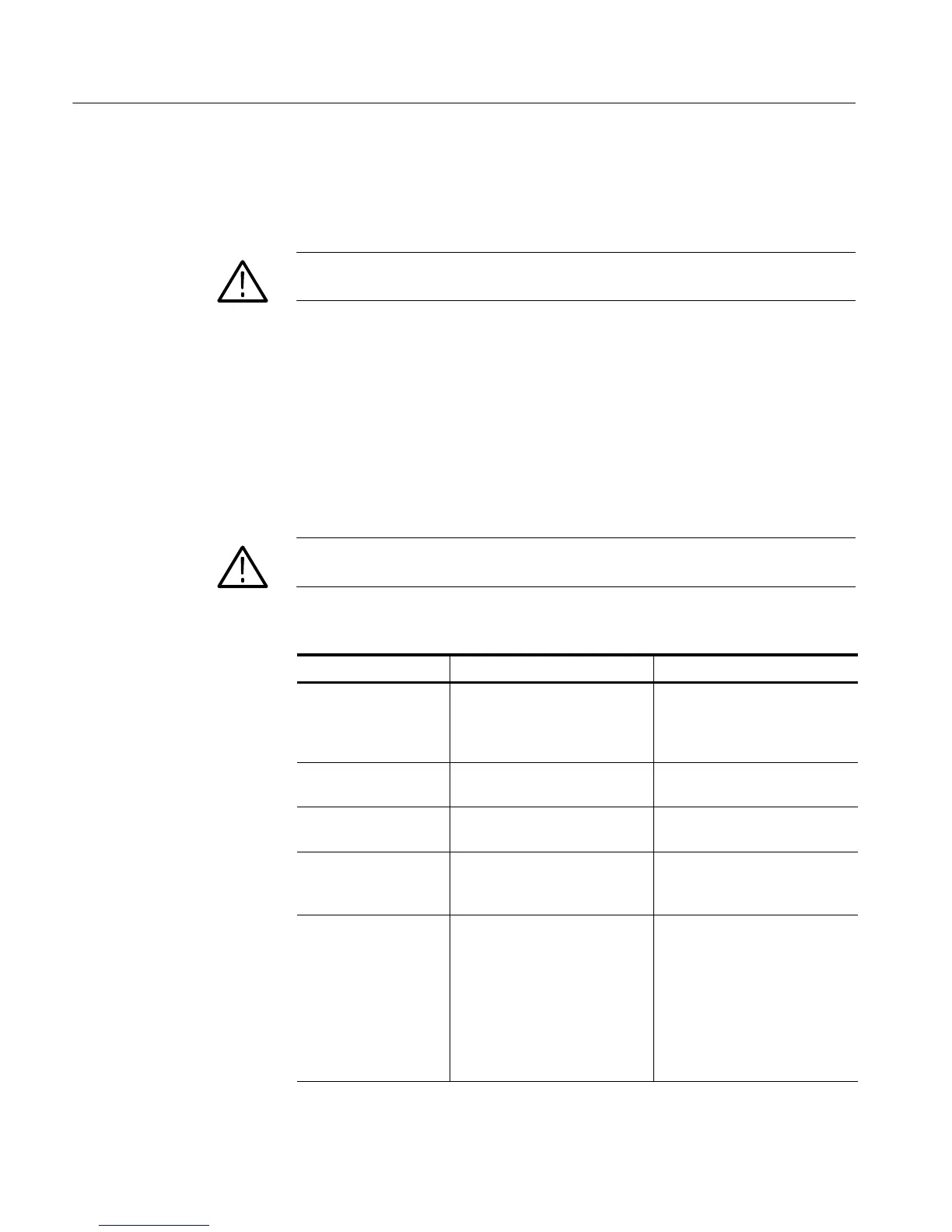

Table 6- 2: Internal inspection check list

Item Inspect for Repair action

Circuit boards Loose, broken, or corroded

solder connecti ons. Burned

circuit boards. Burned, broken, or

cracked circuit-run plati ng.

Remove and replace damaged

circuit board.

Resistors Burned, cracked, broken, blis-

tered condition.

Remove and replace damaged

circuit board.

Solder connecti ons Cold solder or rosin joints. Resolder joint and clean with

isopropyl alcohol.

Capacitors Damaged or leaking cas es.

Corroded solder on leads or

terminals.

Remove and replace damaged

circuit board.

Semiconductors Loosely inserted in sockets.

Distorted pins.

Firmly seat loose semiconduc-

tors. Remove device s that have

distorted pins. Carefully straight-

en pins (as required to fit the

socket), using long-nose pliers,

and reinsert firmly. Ensure that

straightening action does not

crack pins, causing them to

break off.

Loading...

Loading...