Natrix IOM

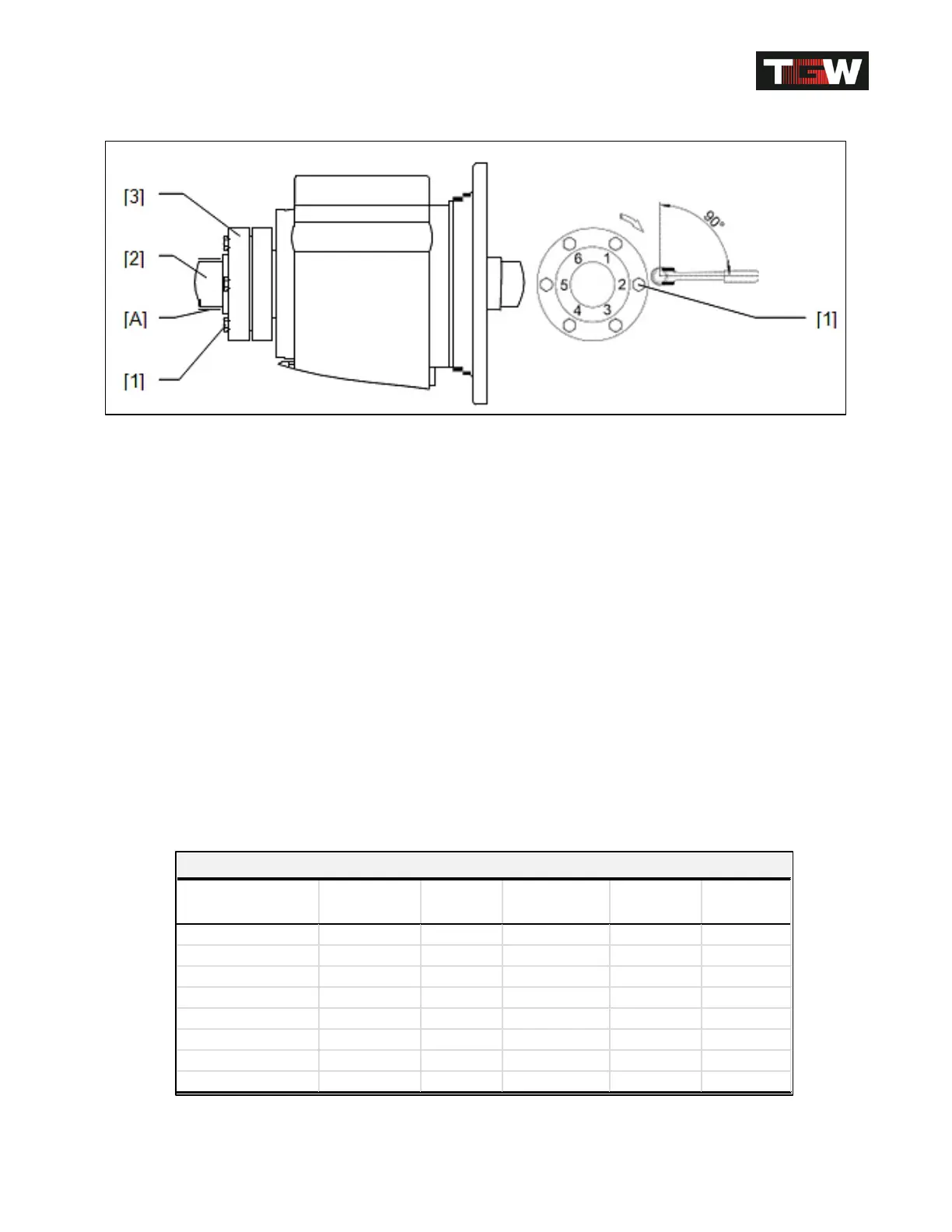

Shrink Disc Removal Procedure

Disassemble shrink disc [3]

Loosen clamping screws [1] evenly one by one.

Attention: Loosen all clamping screws by a 90° turn first to prevent the outer rings

from tilting!

Dismantle shaft [2] or pull off the hub from the shaft. Always remove the rust that may

have formed on the shaft in front of hub [A] before removing the disc.

Pull off shrink disc [3] from the hub.

Please note: Disassembled shrink discs do not need to be dismantled and lubricated

before they are clamped again.

Only if the shrink disc is dirty, it will have to be cleaned and

lubricated Lubricate

the

tapered surfaces with Molykote 321 (dry film lubricant) or similar Lubricate the clamping

screws with Molykote BR2 (multiple-purpose grease) or similar.

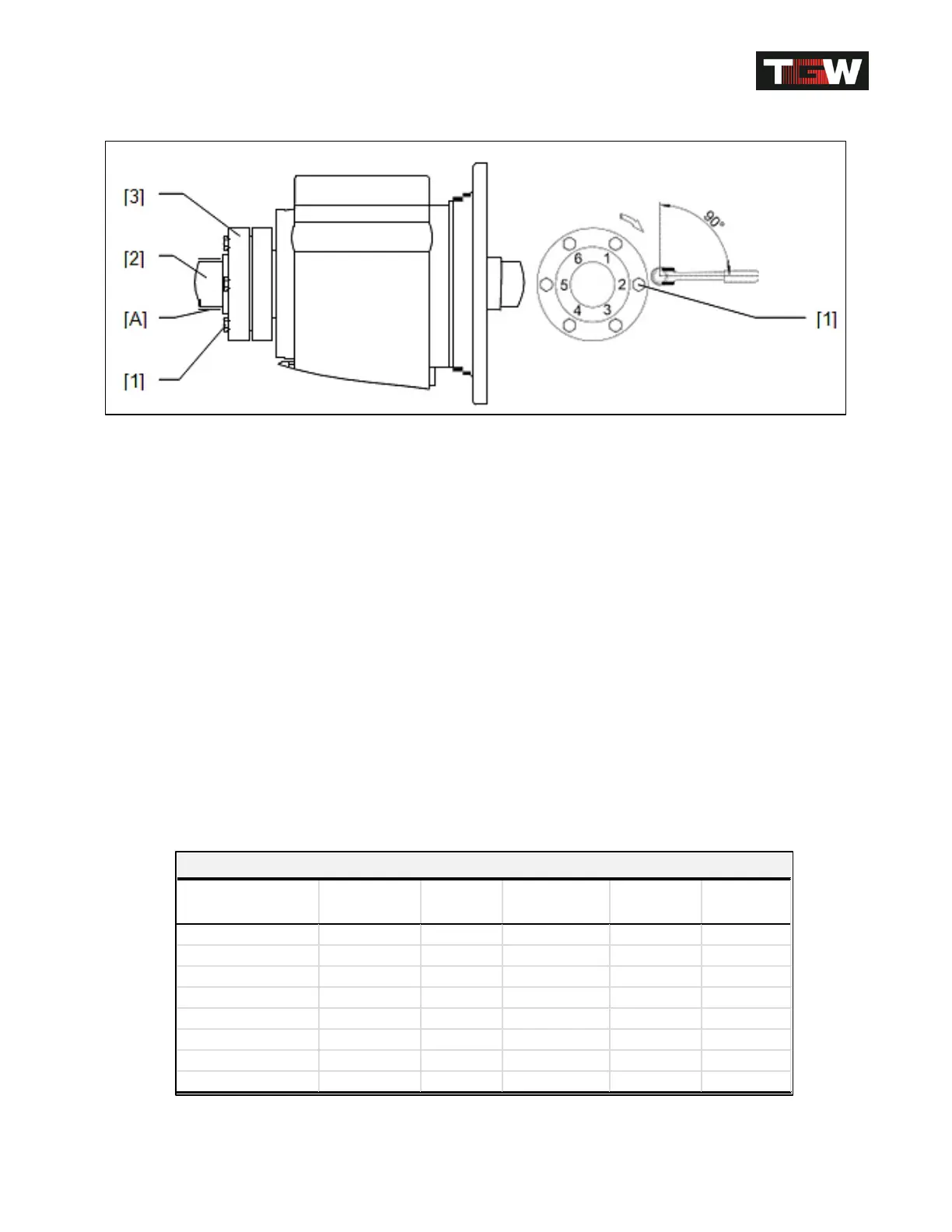

Motor Shrink Disc Requirements

Lenze GKS07 50

≈ 2" 30Nm 22.1 Ft / Lbs

Lenze

GKS09 65 ≈ 2-1/2" 70Nm

51.6 Ft / Lbs

Lenze GKS11 80 ≈ 3-1/8"

59Nm 43.5 Ft / Lbs

SEW KH67 40 ≈ 1-9/16" 12Nm

8.9 Ft / Lbs

SEW KH87 65 ≈ 2-9/16" 30Nm

22.1 Ft / Lbs

SEW KH97 75 ≈ 2-15/16" 30Nm 22.1 Ft / Lbs

Siemens

K63 50 ≈ 2 70Nm 51.6 Ft / Lbs

Siemens

K83 70 ≈ 2-3/4" 70Nm 51.6 Ft / Lbs

Shrink Disc Mounting Screw Requirements

Revision Date: 12/10/2014 Page 64 of 111

Loading...

Loading...