Natrix IOM

Drive Station Tension Timing Belt

Tension timing belt

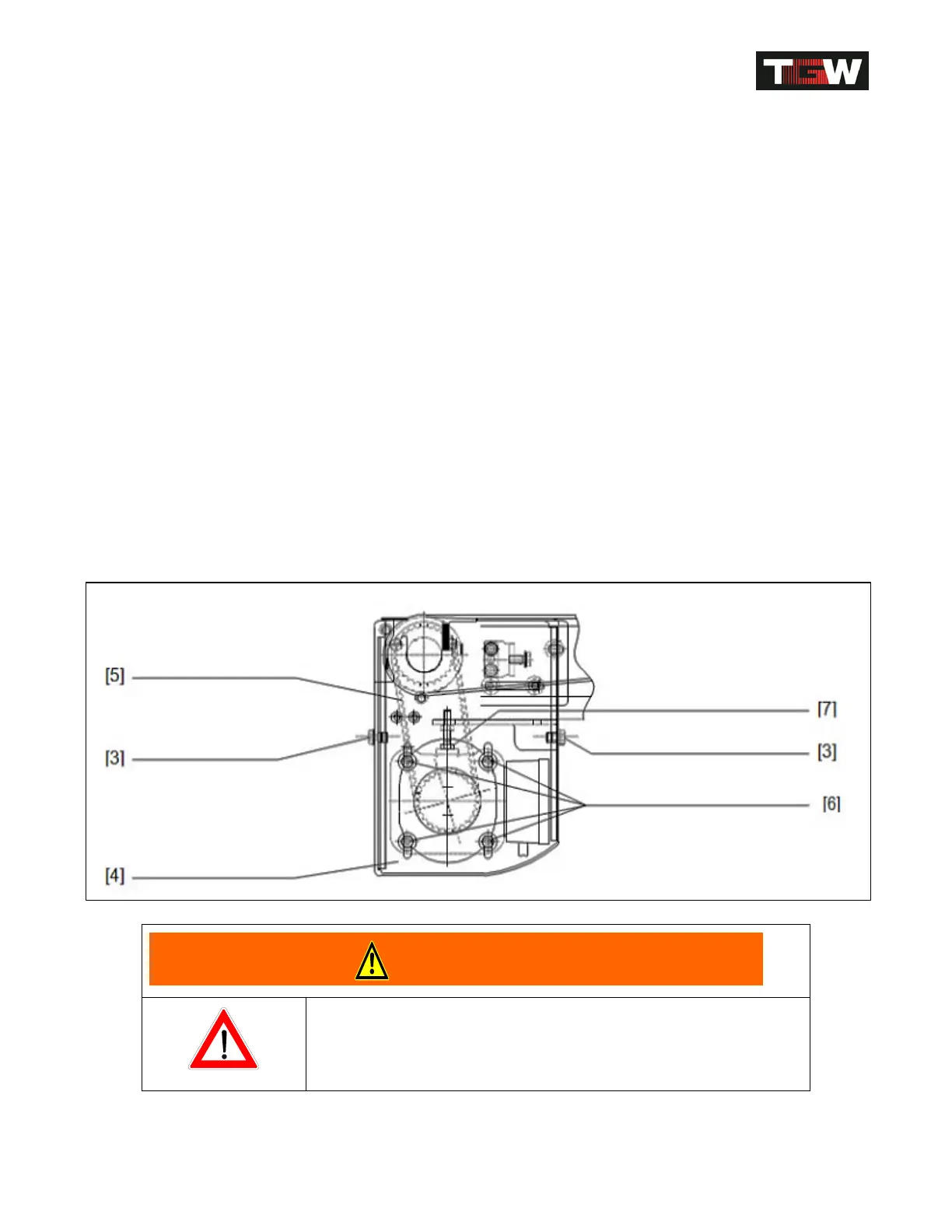

Loosen screws [3] and remove cover [4].

Loosen screws [6].

Tension the timing belt using tightening screw [7].

After belt adjustment is completed tighten screws [6].

Press measuring spring scale [1] (00078151) in the middle on the back of the belt

between the pulleys and adjust tension until the timing belt touches the aluminum strut

with a spring force of 7 ± 1kg (15 ± 2Lbs.) [2] (see sketch).

Position frequency measuring device [8] (00074597) in the middle on the back of the

belt between the pulleys and pluck the belt.

Read the measured value and compare it to 90 Hz ± 10.

If the two values do not match, adjust tension up or down as needed.

• The fixing screws of the motor flange must be

tightened when reading off the test load!

Revision Date: 12/10/2014 Page 96 of 111

Loading...

Loading...