Natrix IOM

Conveyor Belt Tracking

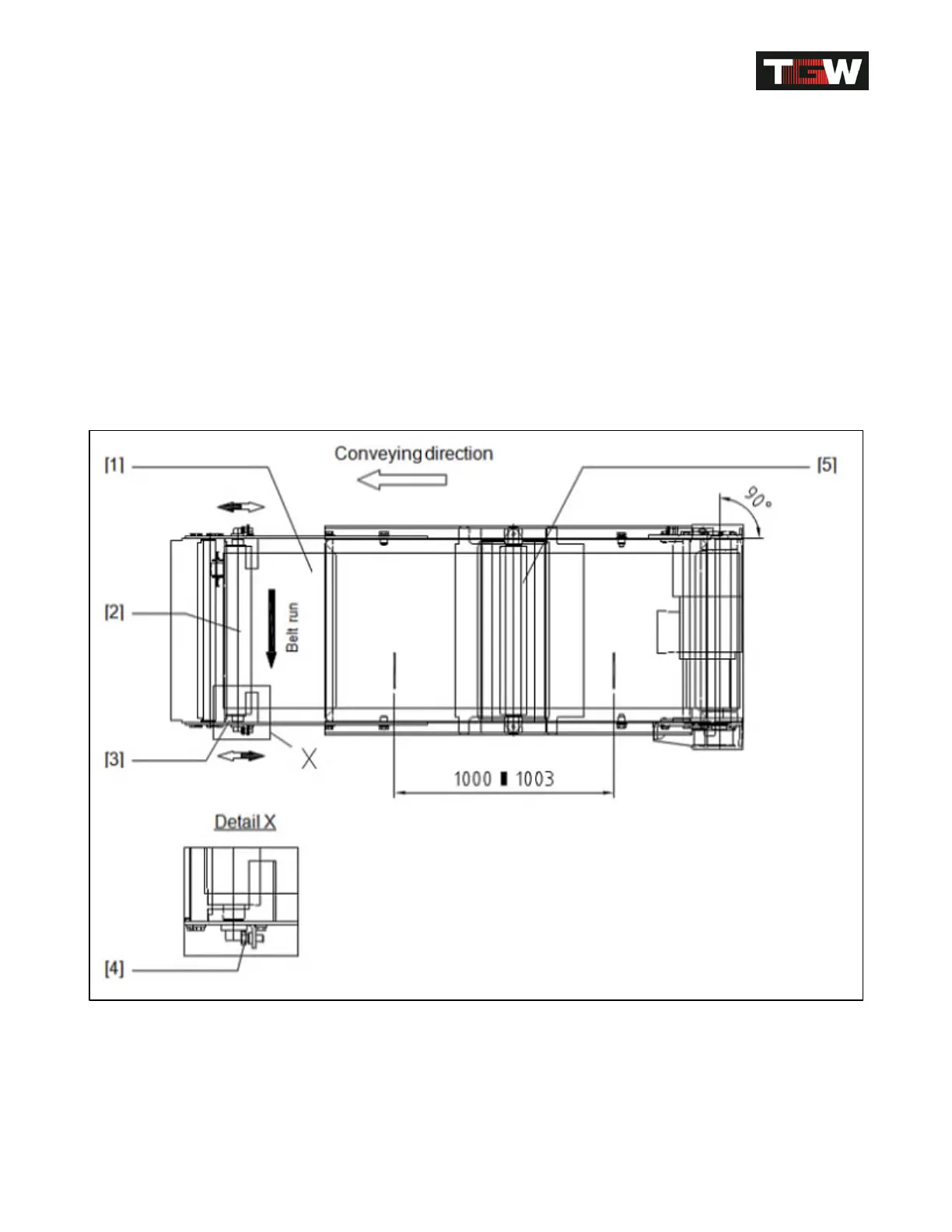

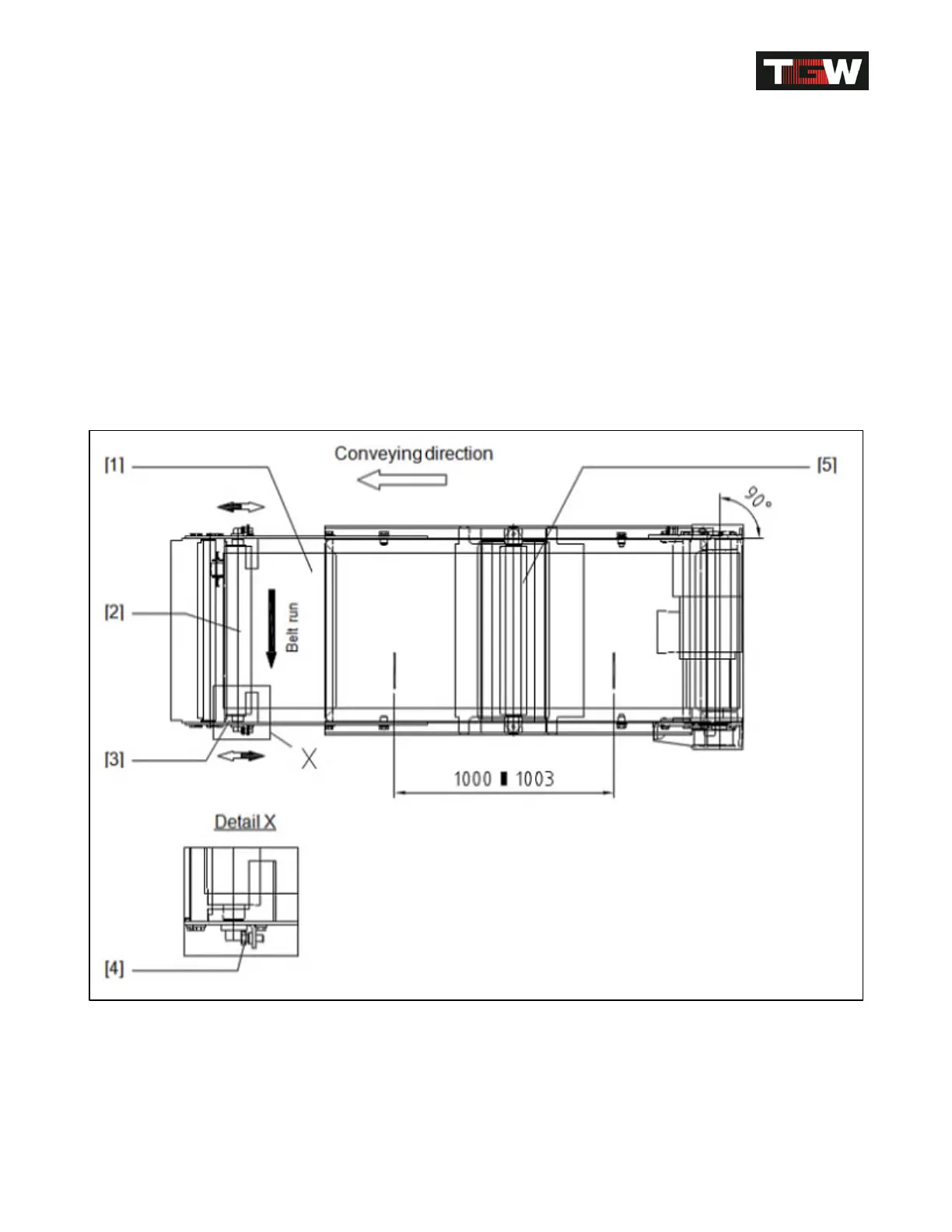

• Check whether all conveyor rollers and pulleys are positioned perpendicular to the

conveyer side frames [1]

• Make sure the belt tension is correct (0.25% - 0.30%)

•

Correct the belt tension by adjusting the tension pulley [5].

When the belt is running:

• To make belt run parallel.

• Correct the belt alignment by adjusting the return pulley [2].

o For example, tensioning the discharge roller [3] on one side or the other causes

the belt to move to opposite side of the conveyor.

• Loosen the lock nut and tighten or loosen either of the screws [4] by turning them

clockwise or counterclockwise.

Revision Date: 12/10/2014 Page 95 of 111

Loading...

Loading...