Multi Pro 1750Page 7 − 42Drive Train

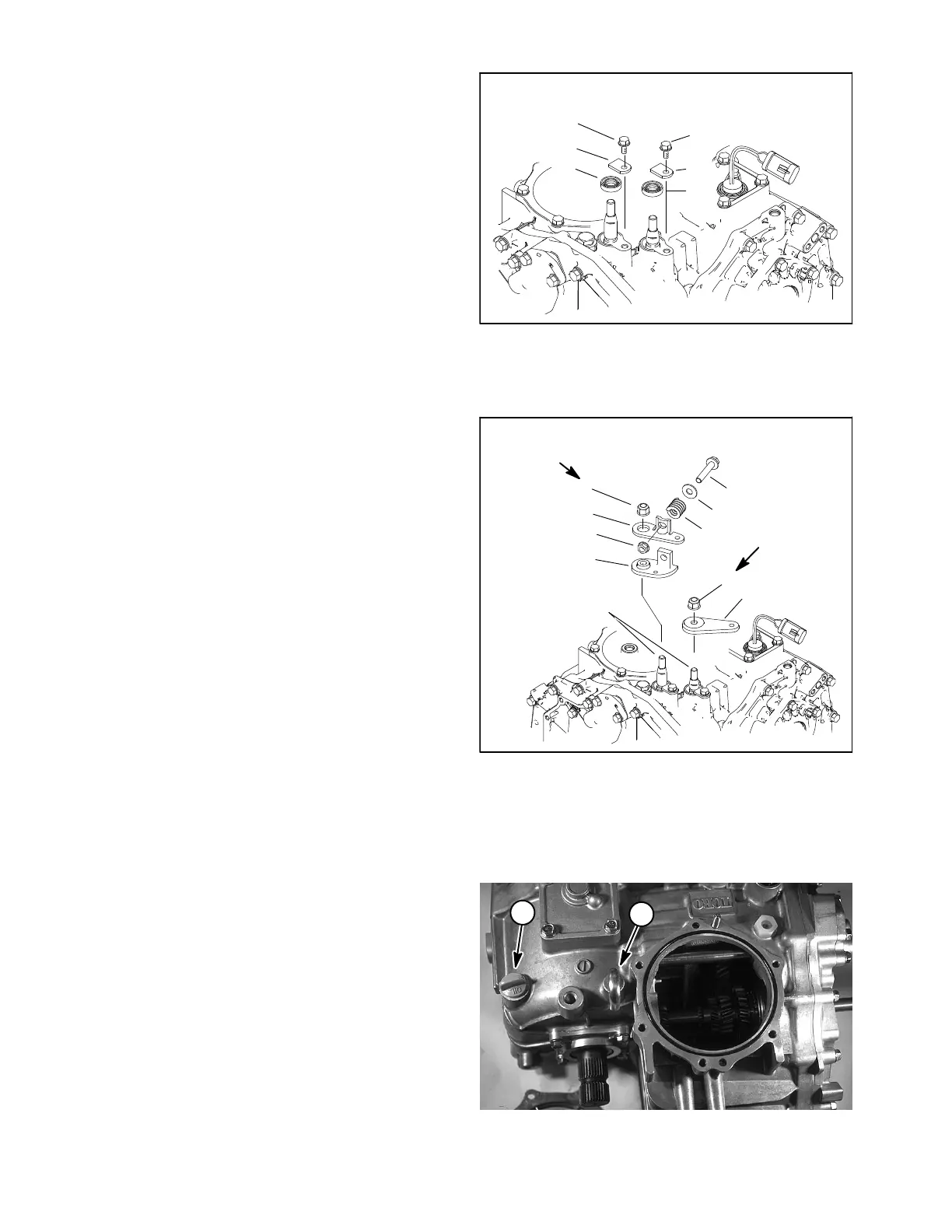

12.Assemble shift arms:

A. Apply multi−purpose grease on lips of oil seals

and install new shift arm oil seals in transaxle case.

B. Install keeper plates and tighten flange head

screws to a torque from 11 to 13 ft−lb (15 to 17

N−m).

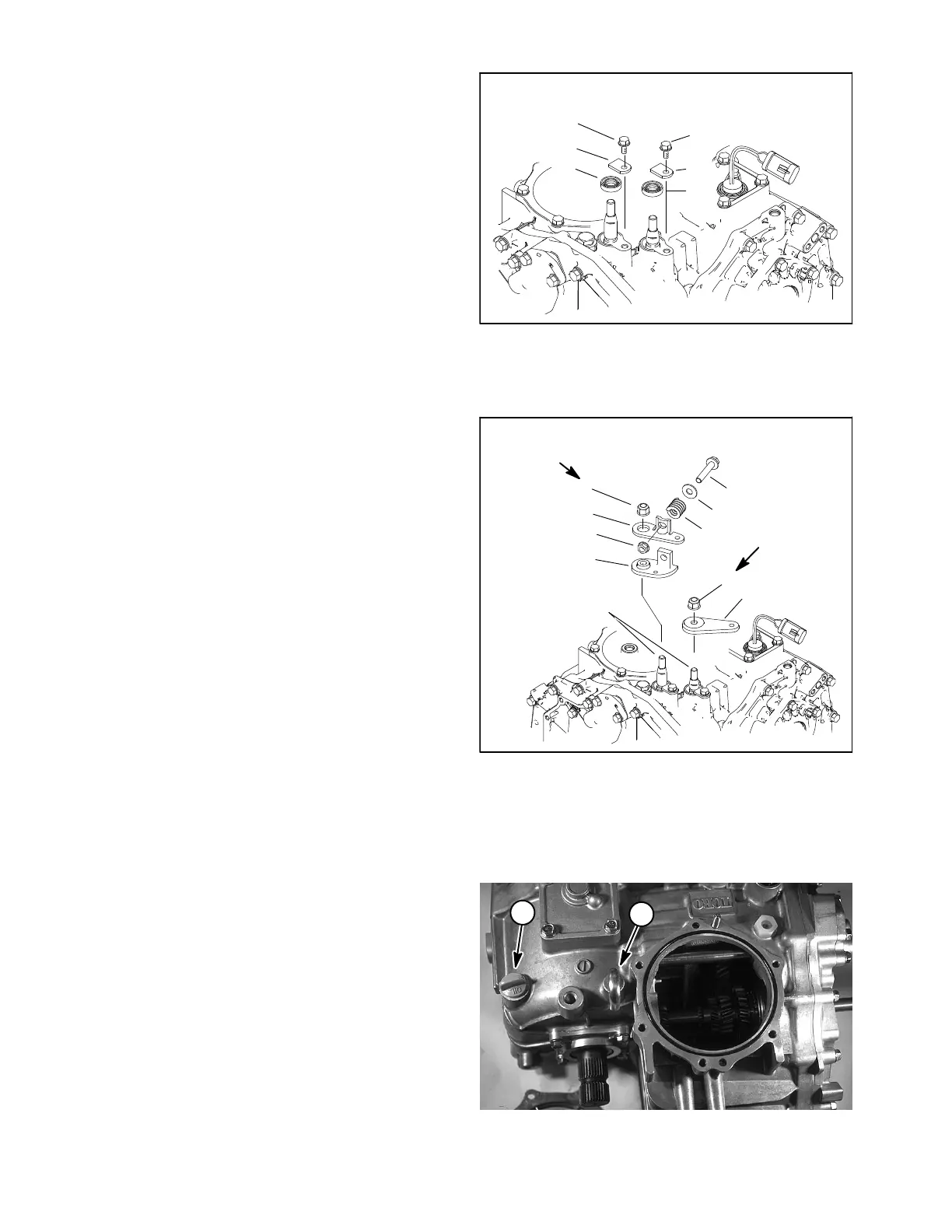

C. Apply high strength bonding compound (ie. Loc-

tite #680) to tapers of shift fork arms.

D. Install shift arms. Install shift arm assembly.

E. Install lock nuts. Tighten shift arm retaining lock

nuts to a torque from 230 to 240 in−lb (26 to 27

N−m).

1. Cap screw (2)

2. Keeper plate (2)

3. Oil seal (2)

Figure 72

3

1

2

3

1

2

11 to 13 ft−lb

(15 to 17 N−m)

230 to 240 in−lb

(26 to 27 N−m)

Figure 73

1. Nut

2. 2

nd

−3

rd

shift arm

3. Shift arm plate

4. Spring

5. Lock nut

6. Washer

7. Cap screw

8. Lock nut

9. 1st−Rev shift arm

Apply Loctite #680

to threads and tapers

3

1

2

4

5

6

7

8

9

230 to 240 in−lb

(26 to 27 N−m)

13.Install oil cap with O−ring. Apply multi−purpose

grease to O−ring.

14.If removed, install air breather. Use sealing tape on

threads of air breather.

1

2

1. Oil cap 2. Air breather

Figure 74

Loading...

Loading...