E6581158

M-2

13

(Continued)

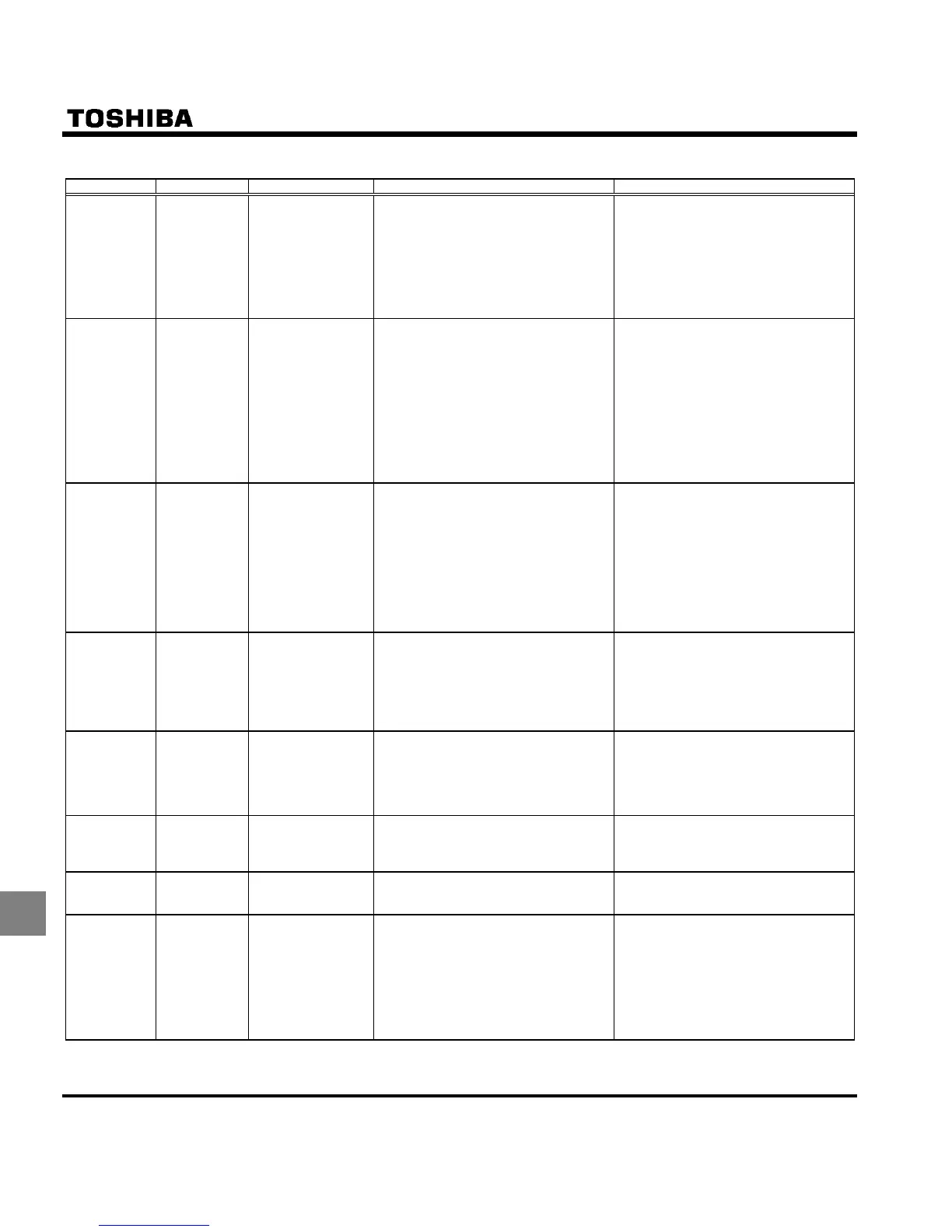

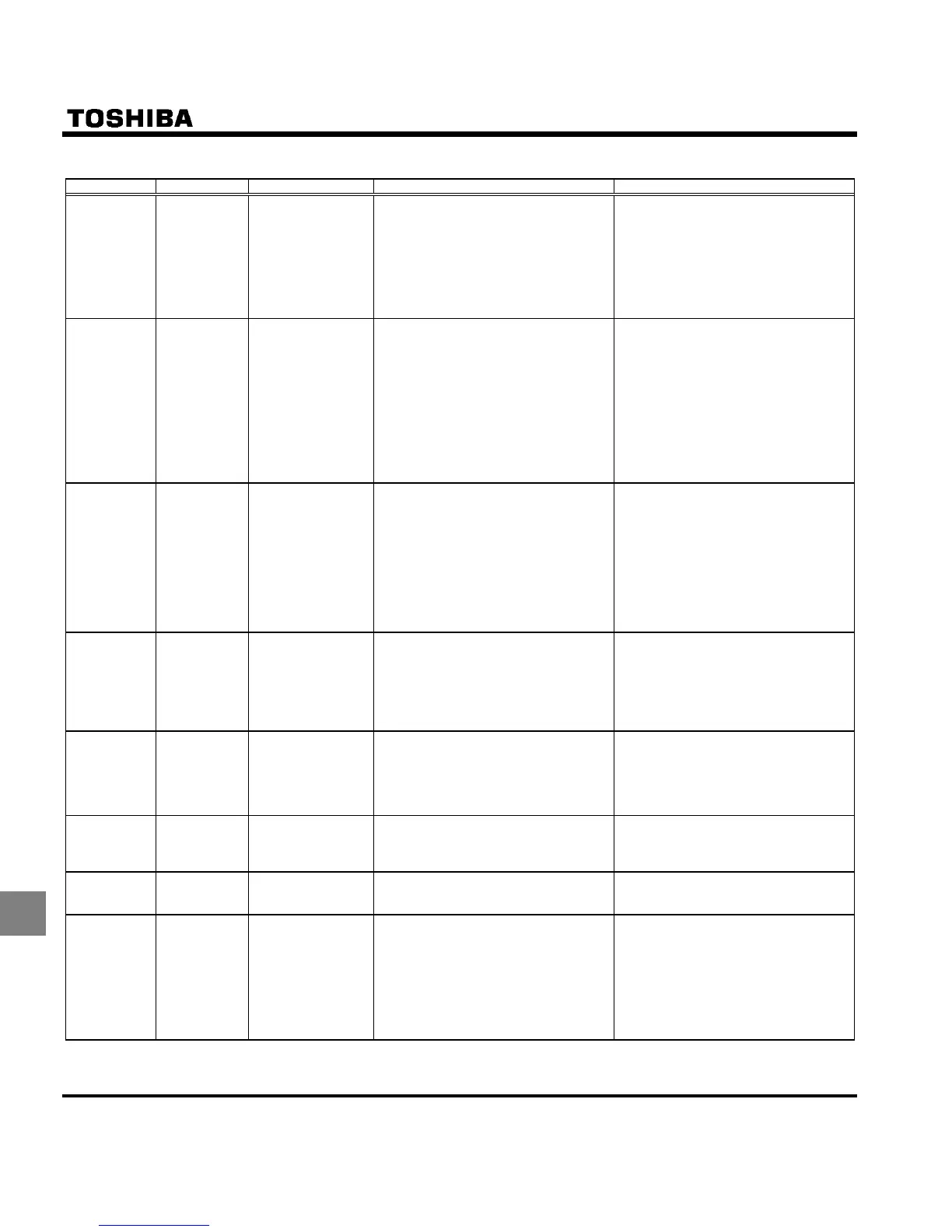

Error code Failure code Problem Possible causes Remedies

QR

000A Overvoltage during

acceleration

• The imput voltage fluctuates abnormally.

(1) The power supply has a capacity of

200kVA or more.

(2) A power factor improvement capacitor is

opened or closed.

(3) A system using a thyrister is connected

to the same power distribution line.

• A restart signal is input to the rotating

motor after a momentary stop, etc.

• Insert a suitable input reactor.

• Use H (auto-restart) and H

(ride-through control).

QR

000B Overvoltage during

deceleration

• The deceleration time FGE is too short.

(Regenerative energy is too large.)

• H (dynamic braking resistor) is off.

• H (overvoltage limit operation) is

off.

• The input voltage fluctuates abnormally.

(1) The power supply has a capacity of

200kVA or more.

(2) A power factor improvement capacitor is

opened and closed.

(3) A system using a thyrister is connected

to the same power distribution line.

• Increase the deceleration time FGE.

• Install a dynamic braking resistor.

• Enable H (dynamic braking resis-

tor).

• Enable H (overvoltage limit opera-

tion).

• Insert a suitable input reactor.

QR

000C Overvoltage during

constant-speed op-

eration

• The input voltage fluctuates abnormally.

(1) The power supply has a capacity of

200kVA or more.

(2) A power factor improvement capacitor is

opened or closed.

(3) A system using a thyrister is connected

to the same power distribution line.

• The motor is in a regenerative state be-

cause the load causes the motor to run at

a frequency higher than the inverter out-

put frequency.

• Insert a suitable input reactor.

• Install a dynamic braking resistor.

QN

000D Inverter overload

• The acceleration time ACC is too short.

• The DC braking amout is too large.

• The V/F setting is improper.

• A restart signal is input to the rotating

motor after a momentary stop, etc.

• The load is too large.

• Increase the acceleration time CEE.

• Reduce the DC braking amount H

and the DC braking time H.

• Check the V/F parameter setting.

• Use H (auto-restart) and H

(ride-through control).

• Use an inverter with a larger rating.

QN

000E Motor overload

• The V/F setting is improper.

• The motor is locked up.

• Low-speed operation is performed con-

tinuously.

• An excessive load is applied to the motor

during operation.

• Check the V/F parameter setting.

• Check the load (operated machine).

• Adjust QNO to the overload that the

motor can withstand during operation in a

low speed range.

QNT

000F Dynamic braking re-

sistor

overload trip

• The deceleration time is too short.

• Dynamic braking is too large.

• Increase the deceleration time FGE.

• Increase the capacity of dynamic braking

resistor (wattage) and adjust PBR capac-

ity parameter H.

*

QV

0020 Over-torque trip

• Over-torque reaches to a detection level

during operation.

• Enable H (over-torque trip selec-

tion).

• Check system error.

QJ

0010 Overheat

• The cooling fan does not rotate.

• The ambient temperature is too high.

• The vent is blocked up.

• A heat generating device is installed close

to the inverter.

• The thermistor in the unit is broken.

• Restart the operation by resetting the

inverter after it has cooled down enough.

• The fan requires replacement if it does

not rotate during operation.

• Secure sufficient space around the

inverter.

• Do not place any heat generating device

near the inverter.

• Make a service call.

* You can select a trip ON/OFF by parameters.

(Continued overleaf)

Loading...

Loading...