Power on

22 T2-C User Guide

3 Put the white plastic protector cap on top of the ink tanks.

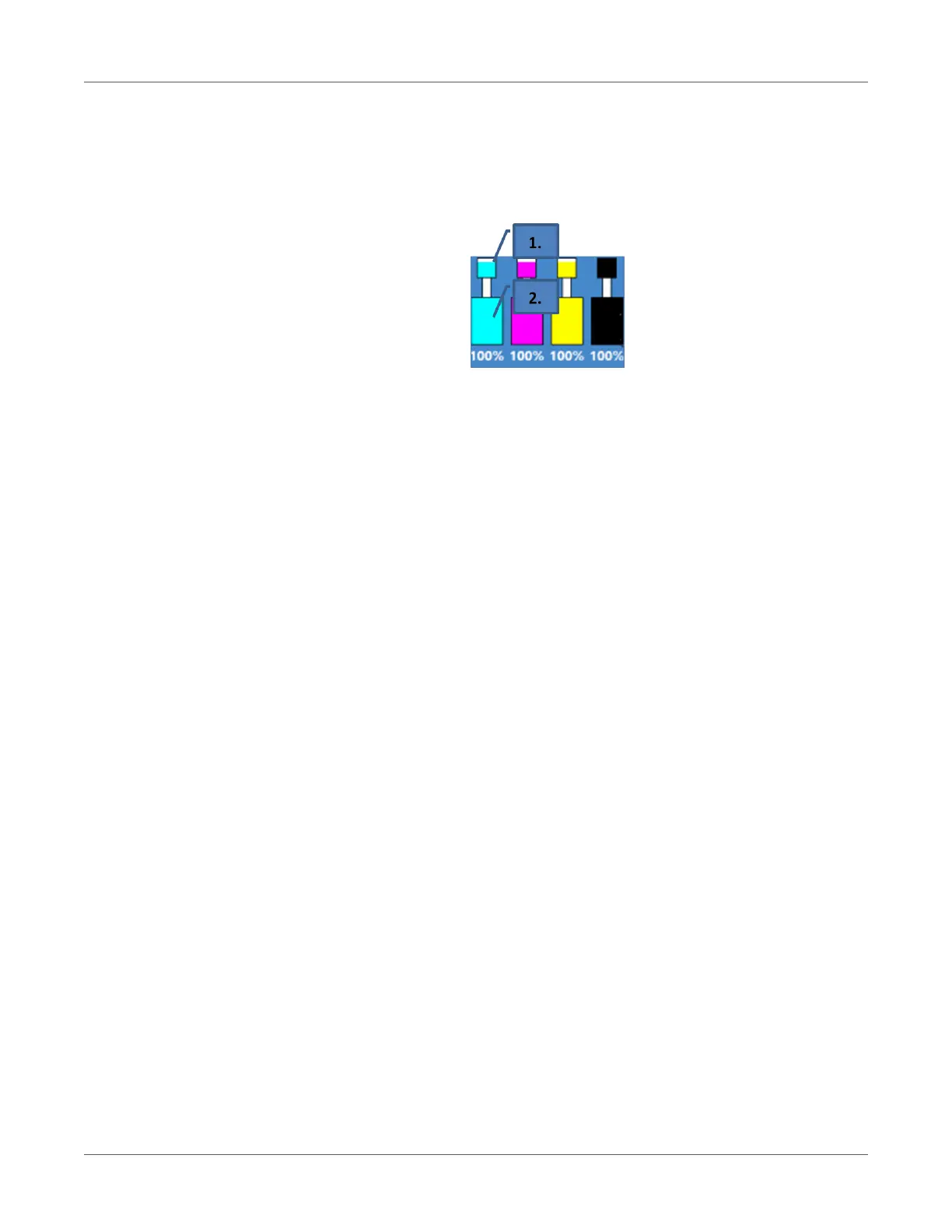

When a 2 liter ink tank is connected, the proper ink level is displayed in percentages in

status bar on the touch screen. Reservoir ink tank levels (1) and 2 liter ink tank levels (2)

are displayed.

During operation, the ink used for printing comes from the built in reservoir ink tanks. The

reservoir tanks have ink level sensors and refilling of these reservoir ink tanks is done from

the 2 liter ink tanks directly. This refilling process is performed automatically by the system

when ink level drops under a certain limit for the particular reservoir ink tank.

During the first time installation when the ink system is empty, after installing the 2L ink

tanks, the system automatically starts filling up the reservoir ink tanks (located inside the

machine) with ink. This is done one by one in CMYK order and the process is displayed on

the screen where the movement of the ink is indicated between 2L ink tank and reservoir

ink tank.

The reservoir ink tanks have the capacity of 200ml and all 4 reservoir ink tanks are around

half full when the process is finished.

The amount of ink used to fill the reservoir ink tanks and tubes for the first time is not

registered back to the QA chip of the 2L ink tanks (ink consumption is measured based on

the ink going through the printhead nozzles), therefore for the first set of ink it is likely that

the 2L ink tanks will run out of ink physically when still around 5% ink level is displayed on

the screen. This is normal and this around 5% ink is not wasted but used to fill the ink

system. From the second ink set, the ink level % calculation is normal and ink tanks run out

of ink according to the ink level % displayed on the screen.

Note: T2-C 2L ink tanks are not refillable and shall be treated as hazardous waste when

empty.

Loading...

Loading...