6.5 Inserting and exchanging tools

NOTICE

Damaging of the spindle or the tool

positions if you use improper tools

Improper tools can damage the collet chuck of the

spindle and / or the tool positions.

Only use tools with a sufficiently large chamfer at

the tool shank.

Install a retaining ring as a stop ring according to

DIN 471-A3.

This does not apply to AirTools.

See the further instructions in chapter Technical

data.

The machine requires different tools for the different

machining strategies during a job.

n

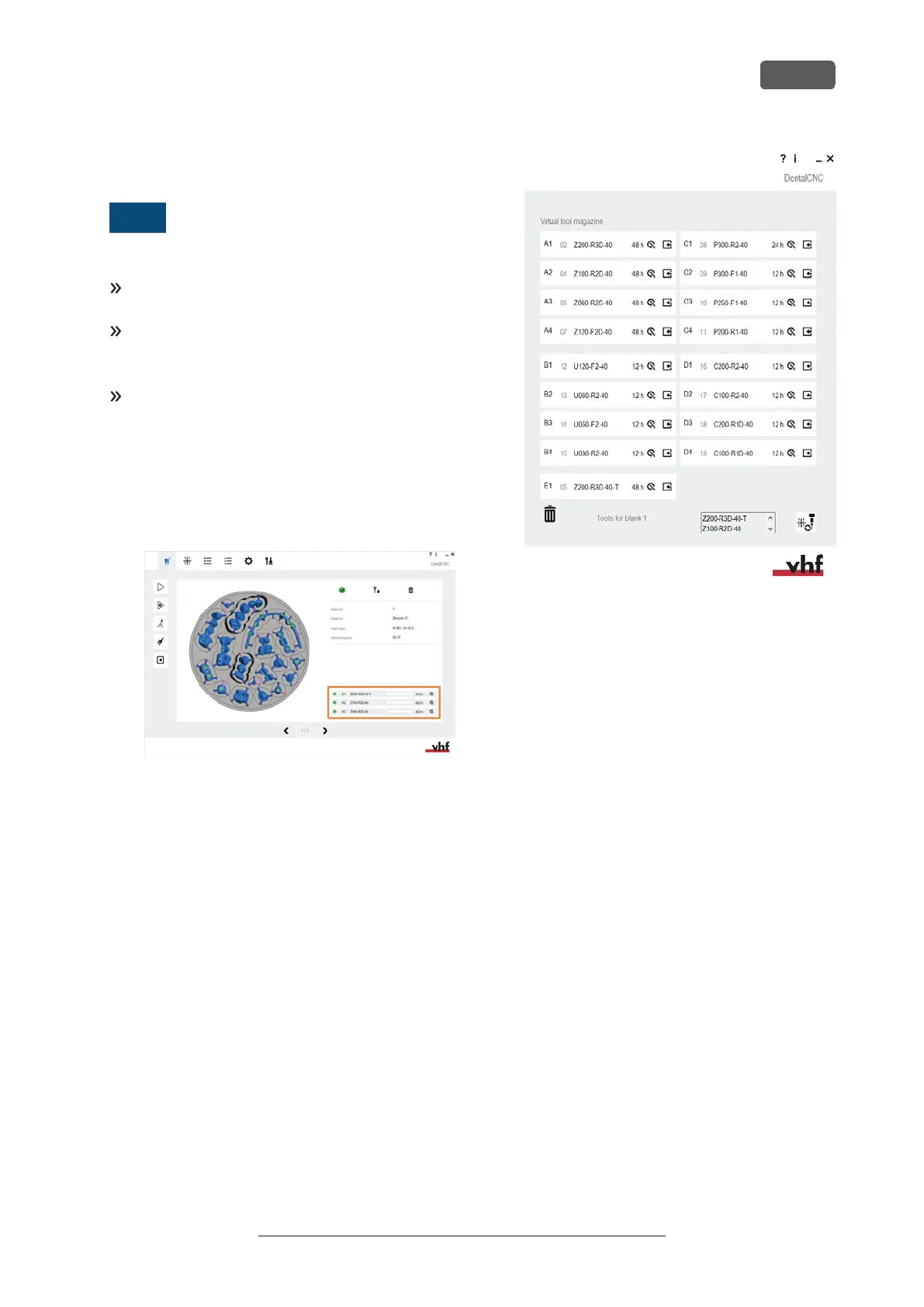

DENTALCNC shows the tools (marked orange)

needed for a job in the Machining view.

FIG. 56

n

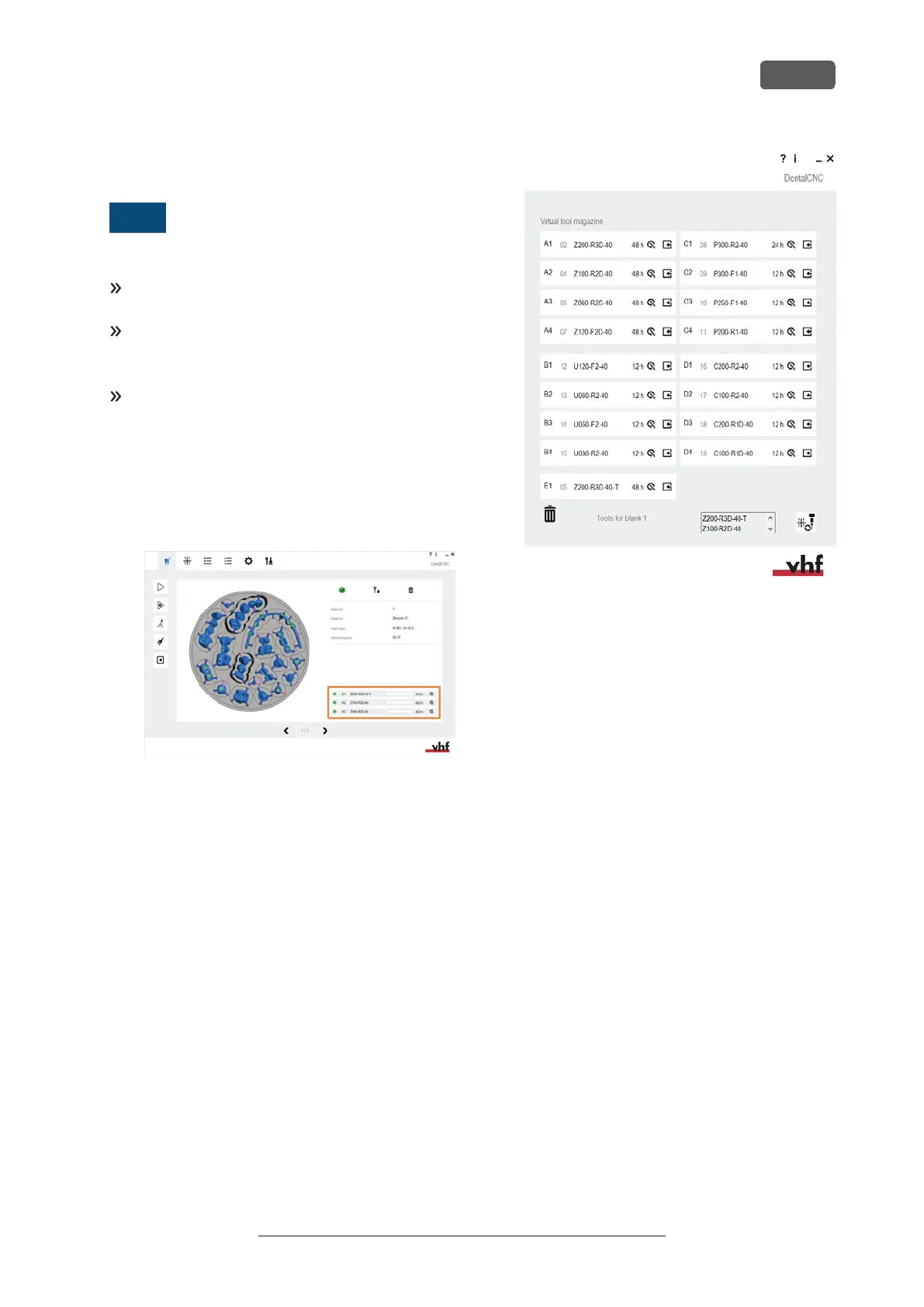

Tools are assigned via the Virtual Tool Magazine

in DENTALCNC.

FIG. 57

6.5.1 Automatic or manual tool change

Tool change can take place automatically via the tool

magazine or manually via the collet chuck. Since each

tool position can be configured individually, automatic

and manual changes are possible in parallel.

Automatic tool change properties

n

The machine automatically loads the necessary

tools from the magazine during machining.

n

You must insert all required tools into the tool

magazine before the order begins.

n

Default case for all tool positions where no

manual change is configured in DENTALCNC.

Automatic tool change is not possible in the following

cases:

n

A tool position is worn out and can no longer

hold any tools properly.

n

You use tools which do not fit into the tool

magazine.

Manual tool change properties

n

During the application, you manually insert the

tools into the spindle’s collet chuck at the request

of DENTALCNC.

Operating the machine

EN 33

Original Operating Instructions: E5

Version: 4/27/2023

Loading...

Loading...