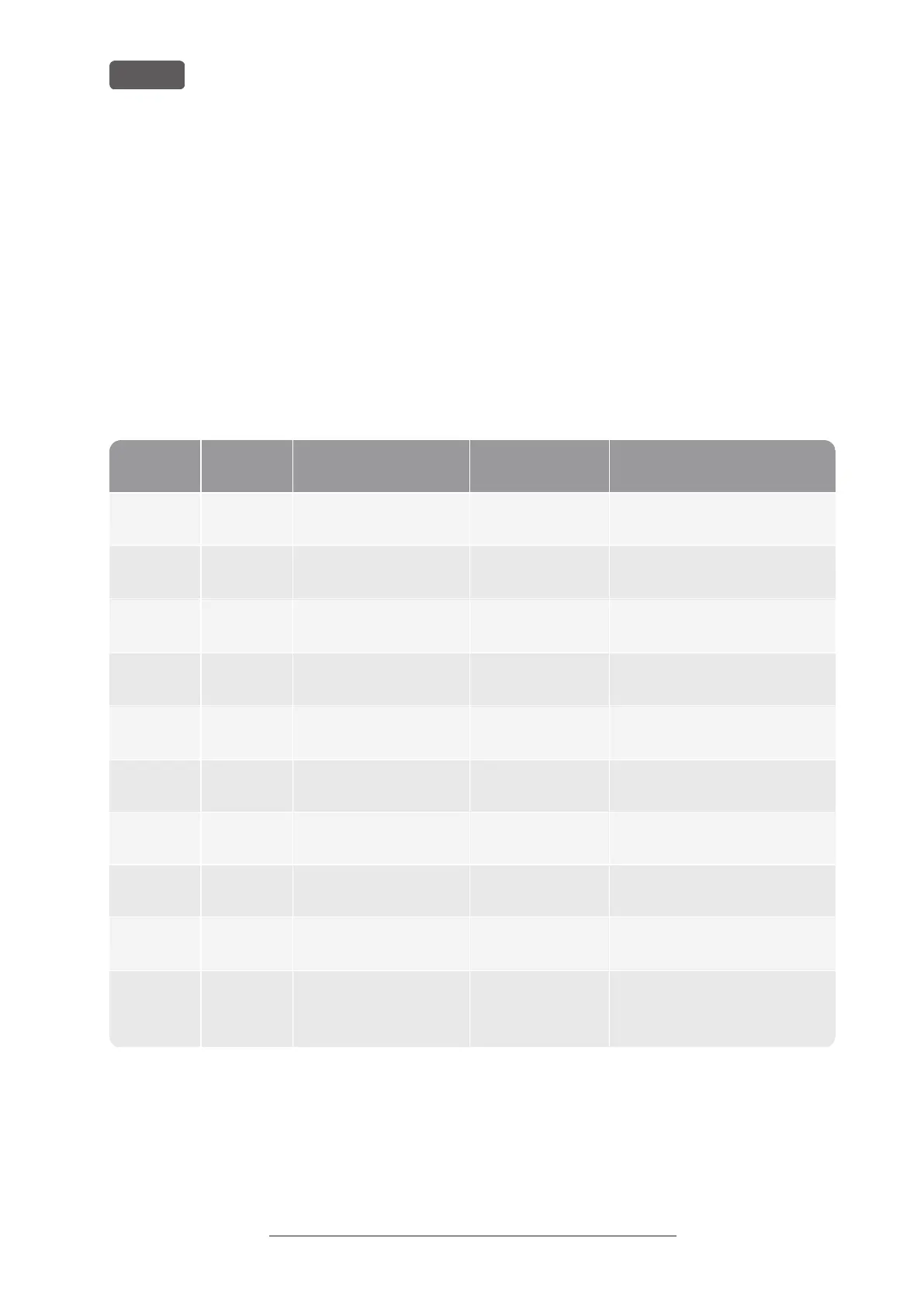

7.7 Spare parts and wear parts

7.7.1 Definition of wear parts

Wear parts are bound to wear out or fail with use. They need to be exchanged within the time intervals which are

given in the table below. Use these values to determine operating costs, to plan your spare part stock as well as to

create individual maintenance and service plans.

7.7.2 Spare part list

In the table below you can find the most important spare parts for your machine.

n

Each supplied accessory can be ordered as a spare part.

n

Customer Service has an extended list of all spare parts.

1 2 Part

Replacement inter-

val or conditions

Description

X X

AirTool insert (E1) 500 operating hours

*

Exchanging tool magazine inserts

and associated holders – on page54

X X

Bellow in the working

chamber

1000 operating hours

*

Exchanging the bellow – on

page59

X X Collet chuck for spindle unit

SFE 300E

500 operating hours

*

Cleaning or replacing the collet

chuck of the spindle – on page47

X X

Spindle unit SFE 300E

(including collet chuck)

2000 operating hours

*

Exchanging the spindle unit – on

page66

X X

Tool magazine insert (A1 -

D4)

500 operating hours

*

Exchanging tool magazine inserts

and associated holders – on page54

X

A-B axis module If defective Exchanging the A-B axis module –

on page90

X

Blank holder If defective Exchanging clamping devices and

blank holders – on page50

X

Blank holder clamping device If defective Exchanging clamping devices and

blank holders – on page50

X

Cover cap for fixing screws of

the A-B axis module

If defective Exchanging the A-B axis module

cover caps – on page87

X

Cover cap for opening the

emergency release

If defective See

Emergency opening of the working

chamber door – on page99

1: Wear part– 2: Self-exchangeable spare part

Maintenance

EN 42

Original Operating Instructions:E5

Version: 4/27/2023

Loading...

Loading...