7.9 Cleaning or replacing the collet

chuck of the spindle

The collet chuck is cleaned and replaced in different

steps:

Step Cleaning Replacing

Removing the collet chuck Yes Yes

Cleaning the collet chuck Yes No

Greasing the collet chuck Yes Yes

Inserting the collet chuck Yes Yes

NOTICE

Damaging of the spindle when cleaning

with compressed air

If you clean the collet chuck with compressed air, the

spindle bearings can be damaged.

Clean the collet chuck only with the appropriate

service set.

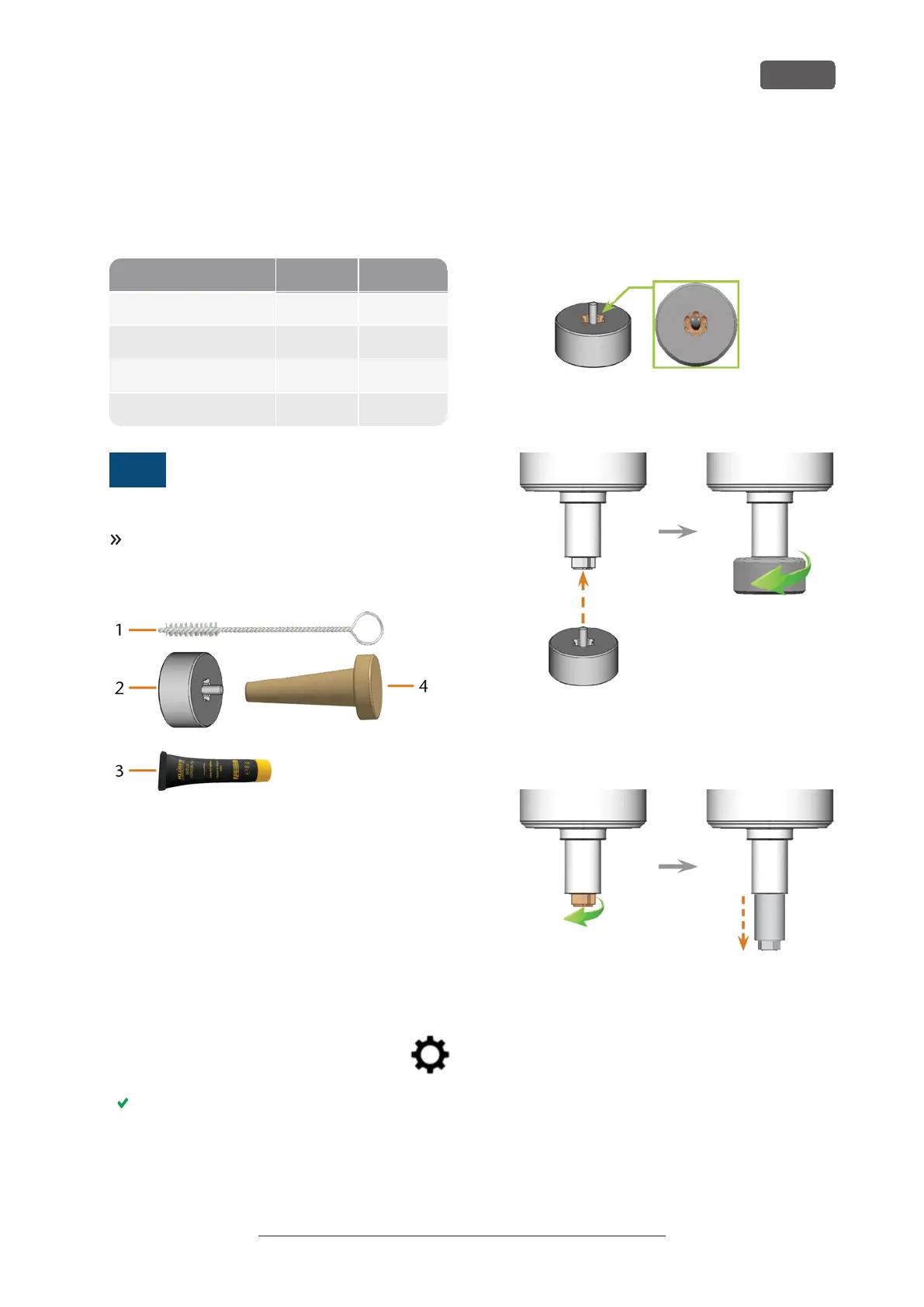

FIG. 78 CURRENT SPINDLE SERVICE SET

1. Cleaning brush

2. Knurled nut

3. Tube of collet chuck grease

4. Cleaning cone

7.9.1 Removing the collet chuck

1. Have the spindle service set ready.

2. Close the working chamber door.

3. Open DENTALCNC‘s general application

settings with the depicted icon in the

main icon bar.

The spindle moves into the position for collet

chuck removal.

4. Open the working chamber door.

5. ⚠ CAUTION! Wear gloves.

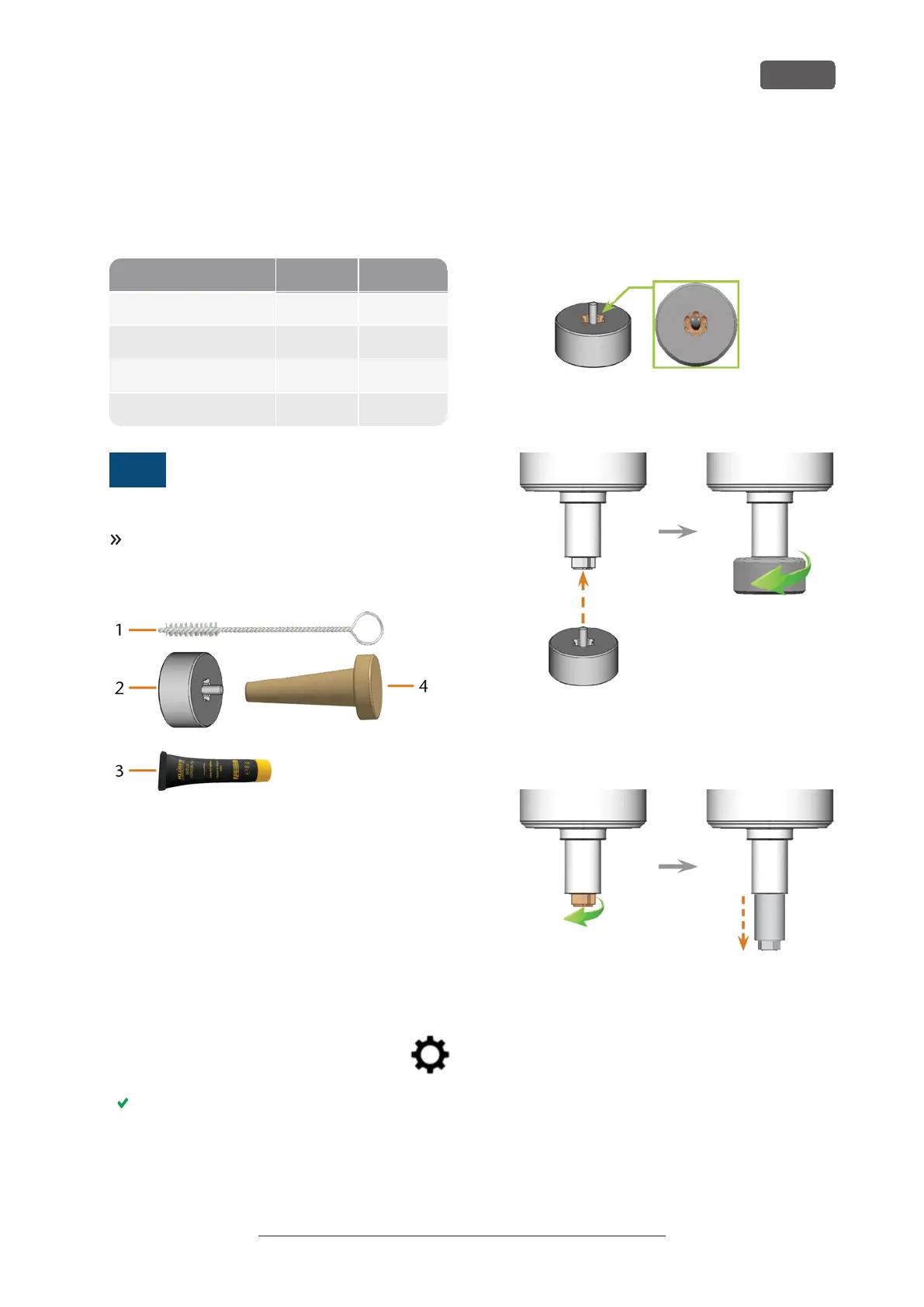

6. Untighten the collet chuck with the knurled nut:

a. Insert the pin of the knurled nut into the

collet chuck.

b. Ensure that the collet chuck is properly seated

in the recess of the knurled nut.

FIG. 79

c. Twist the knurled nut counterclockwise.

FIG. 80

7. Unscrew and remove the collet chuck with your

hand.

FIG. 81

8. Put the knurled nut and the collet chuck aside

within reach.

9. Clean the inner cone of the spindle with the clean-

ing cone of the service set.

Maintenance

EN 47

Original Operating Instructions: E5

Version: 4/27/2023

Loading...

Loading...