94

Maintenance

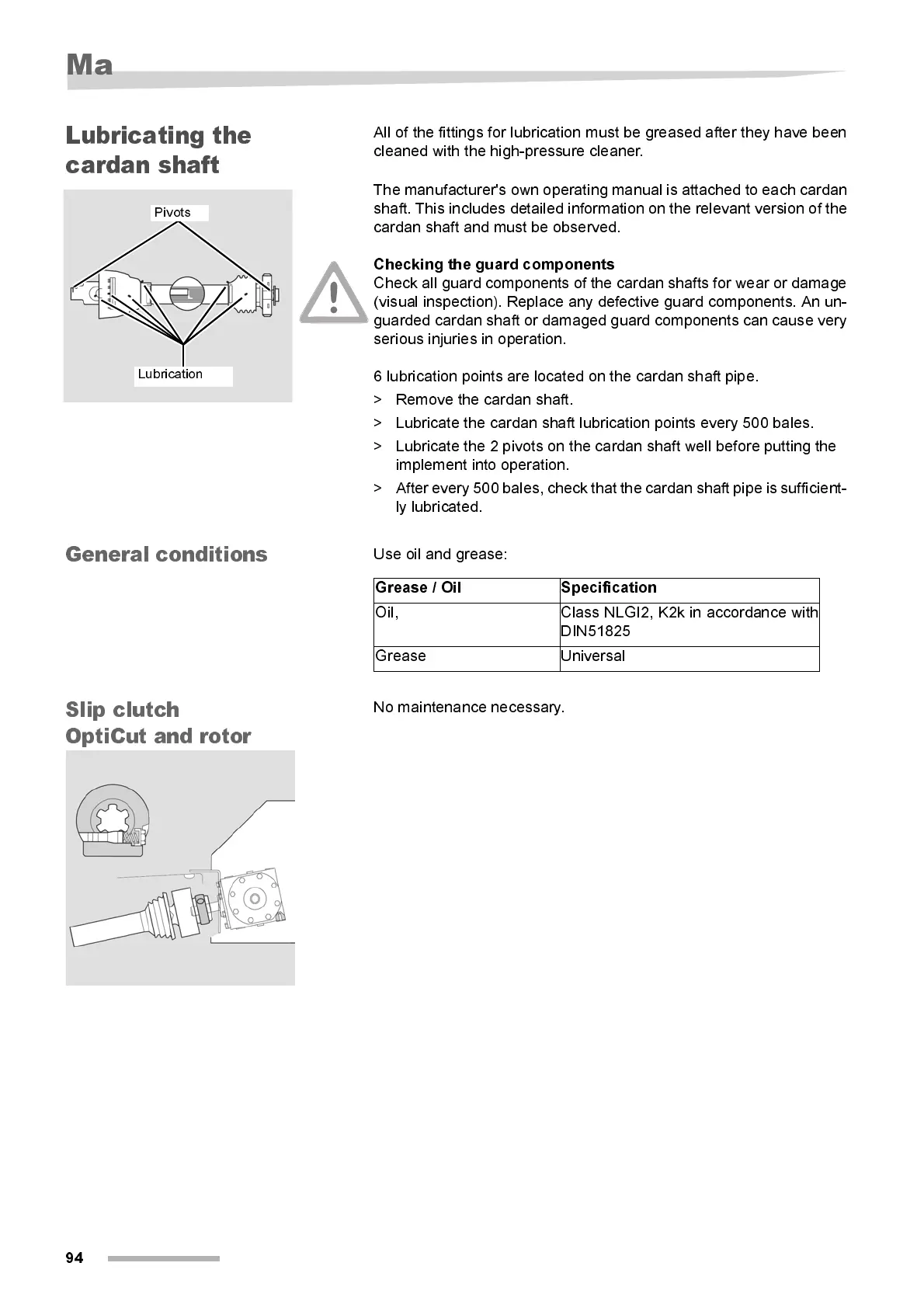

Lubricating the

cardan shaft

Al l of the fi t ti ngs for l ubr icati on must be greased after they have been

cleaned with the high-pressure cleaner.

The manufacturer's own operating manu al is attached to each cardan

shaft. This includes detailed information on the relevant version of the

cardan shaft and must be observed.

Checking the guard components

Check all guard components of the cardan shafts for wear or damage

(visual i nspecti on). Repl ace any defecti ve guard components. An un-

guarded cardan shaft or damaged guard components can cause very

seri ous injuri es in operati on.

6 lubrication points are located on the cardan shaft pipe.

> Remove the cardan shaft.

> Lubri cate the cardan shaft l ubri cat i on points ever y 500 bales.

> Lubricate the 2 pivots on the cardan shaft well before putting the

impl ement into operati on.

> After every 500 bales, check that the cardan shaft pipe is sufficient-

ly l ubricated.

Gene ral con di tio ns

Use oil and grease:

Sli p cl utc h

OptiCut and rotor

No maintenance necessary.

Lubrication

Pivots

Grease / Oil Specification

Oil , Class NLGI2, K2k in accordance wi th

DIN51825

Grease Universal

Loading...

Loading...