4-20 SHB 803 en – Edition 2.4 * 803s410.fm

Engine

4.19 Checking and adjusting valve clearance

☞The standard valve clearance setting is performed on a cold engine:

➥The firing order is 1 – 3 – 2, starter at the 240° position of the crankshaft rotation.

The first cylinder is located on the pump side at the flywheel end opposite the radiator.

Checking valve clearance

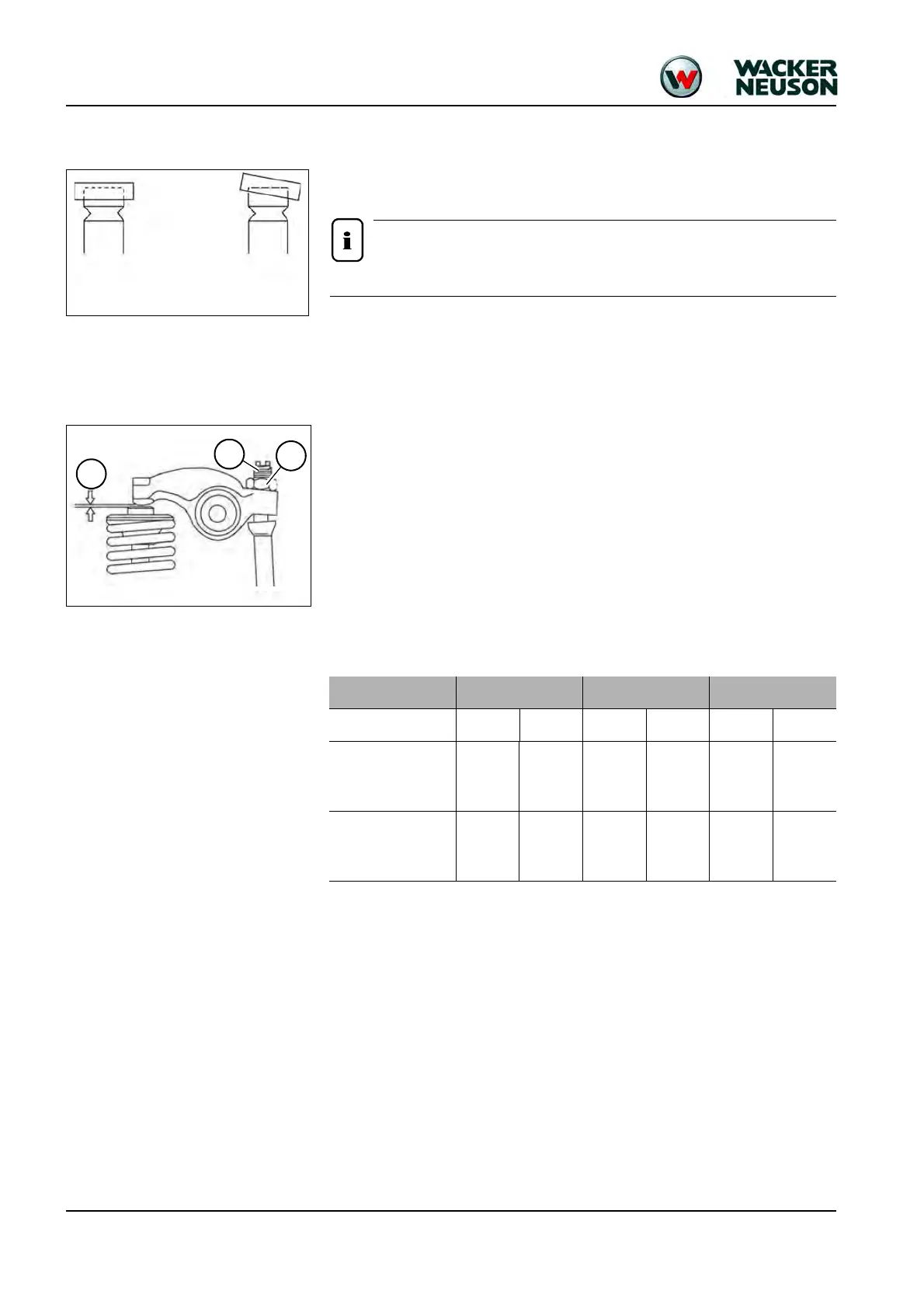

☞Remove the cylinder-head cover.

☞Turn the ring gear on the flywheel clockwise until the cylinder reaches top dead center

of the compression cycle.

➥Both rocker arms are accessible.

➥The intake and exhaust valves can be set in this position.

➥The top dead center mark (indentation) can be seen on the flywheel.

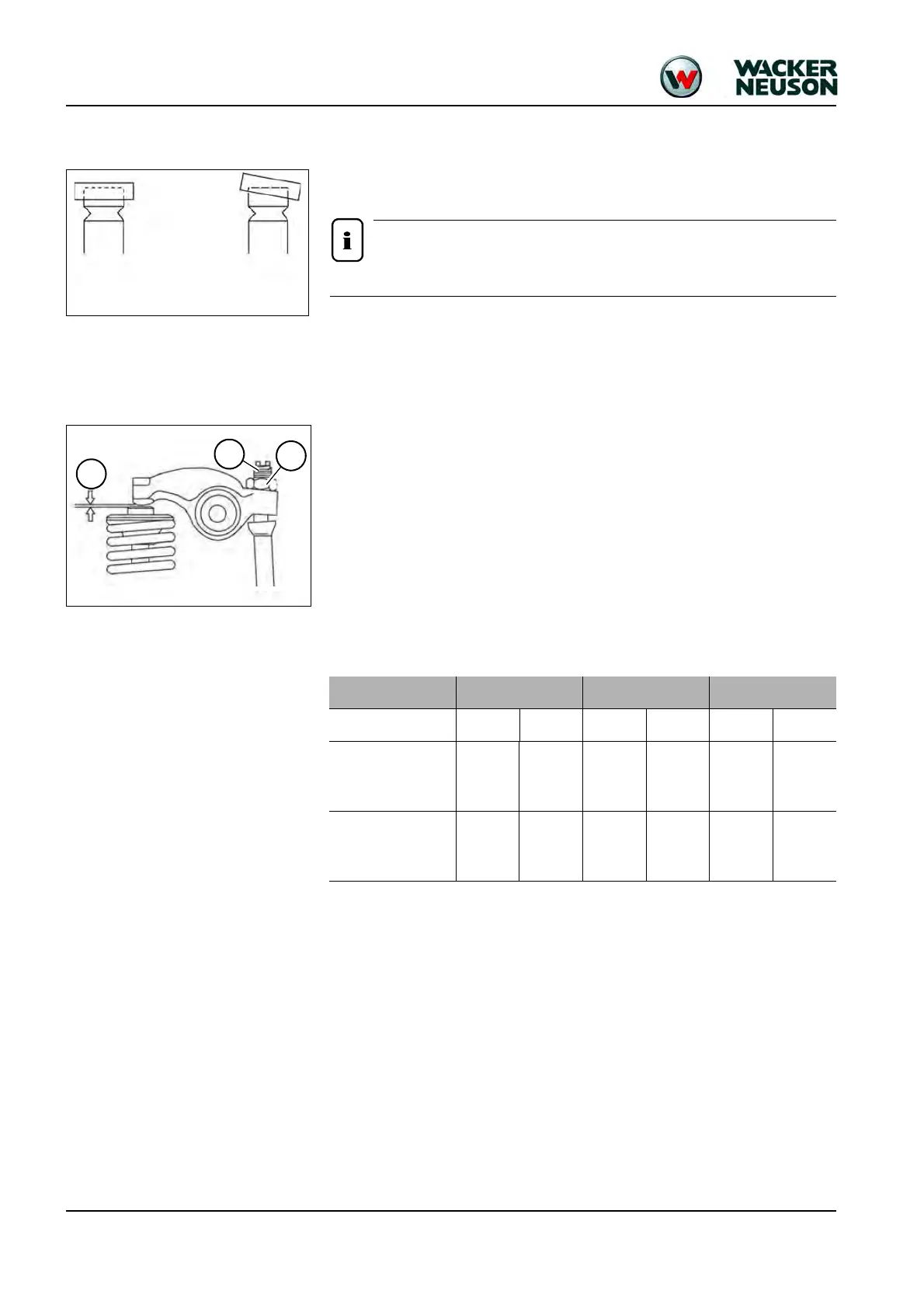

☞Check the valve cap for abnormal wear – see Fig. 22.

☞Check valve clearance with feeler gage A.

➥Valve clearance: 0.15 – 0.25 mm (0.006 – 0.01 in).

☞Adjust the valve clearance if it varies.

To reduce the number of necessary rotations of the crankshaft for checking the valve

clearance, the setting of various valves can be adjusted in parallel in accordance with the

following table:

Example:

• Turn cylinder 1 to top dead center (both valves closed – compression).

➥The valves in the upper row of the table can be set in this manner.

• Then turn the crankshaft to top dead center of the exhaust valve (only the exhaust

valve is open).

➥Both other valves in the lower row of the table can be adjusted.

Fig. 22: Valve cap wear

Abnormal

Normal

Fig. 23: Valve clearance

A

B

C

Cylinder number 1 2 3

Valve Inlet Exhaust Inlet Exhaust Inlet Exhaust

Cylinder 1 at top

dead center

(compression)

●●● ●

Cylinder 1 at top

dead center

(exhaust open)

●●

Loading...

Loading...