4-24 SHB 803 en – Edition 2.4 * 803s410.fm

Engine

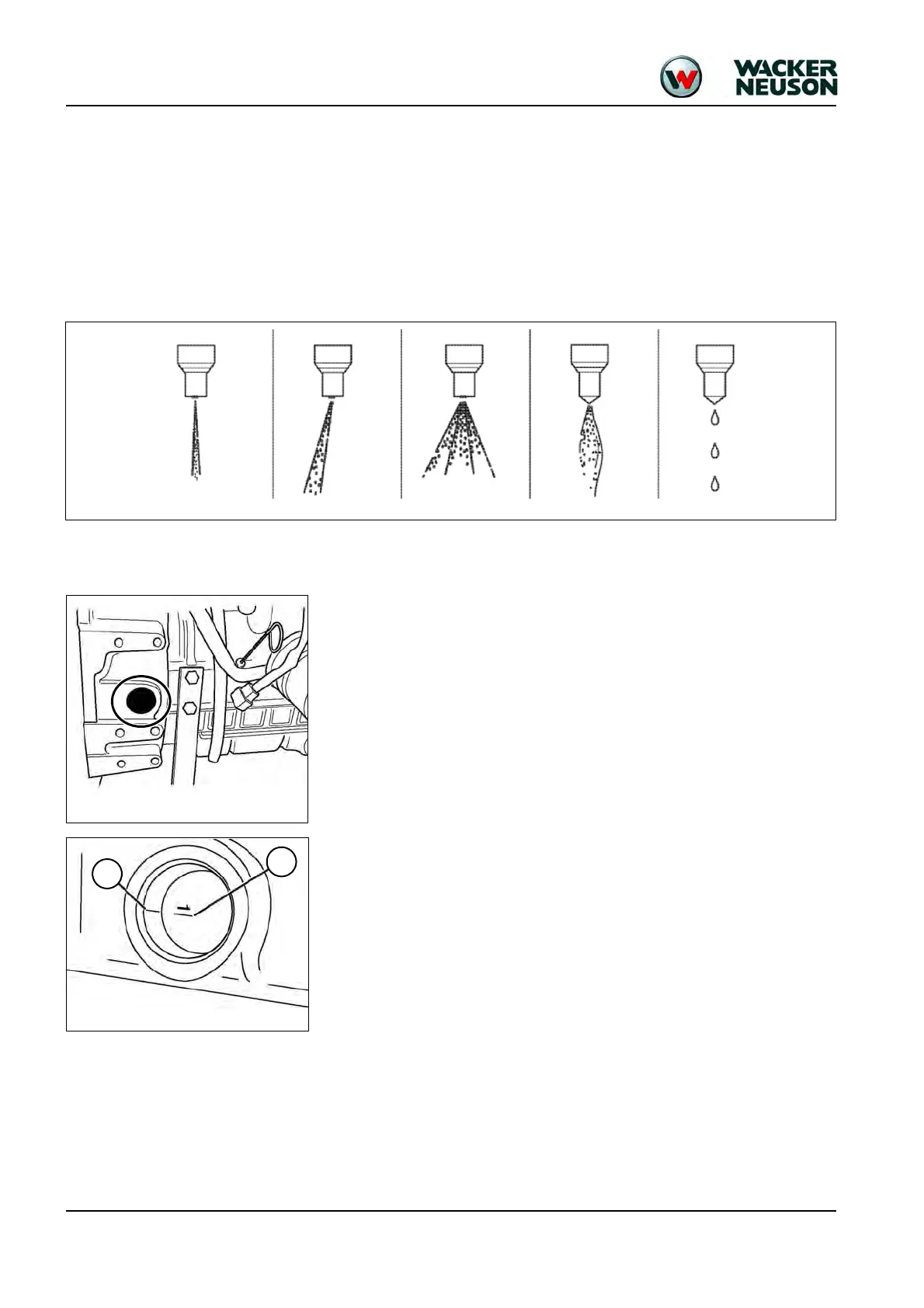

4.22 Checking the nozzle jet

☞Remove the injection lines and the injection nozzles.

☞Connect the injection nozzle with the high pressure line of the nozzle tester.

☞Quickly create pressure until the nozzle ejects fuel (ejection 3 – 4 times).

☞Hold a white sheet of paper about 30 cm (12") away from the nozzle and let the nozzle

eject fuel.

☞The nozzle jet must create a shape on the paper as shown below.

4.23 Injection time

Checking injection time

Preparatory work:

• The fuel system must be filled and bled.

• Clean the injection pump and keep it clean.

☞Checking cylinder 1 is basically sufficient and serves the purpose, but all other cylin-

ders can also be checked.

☞Apply current to the cutoff solenoid, or remove the cutoff solenoid and the O-ring from

the injection pump.

➥Fuel supply is enabled.

☞Set the throttle to the maximum speed.

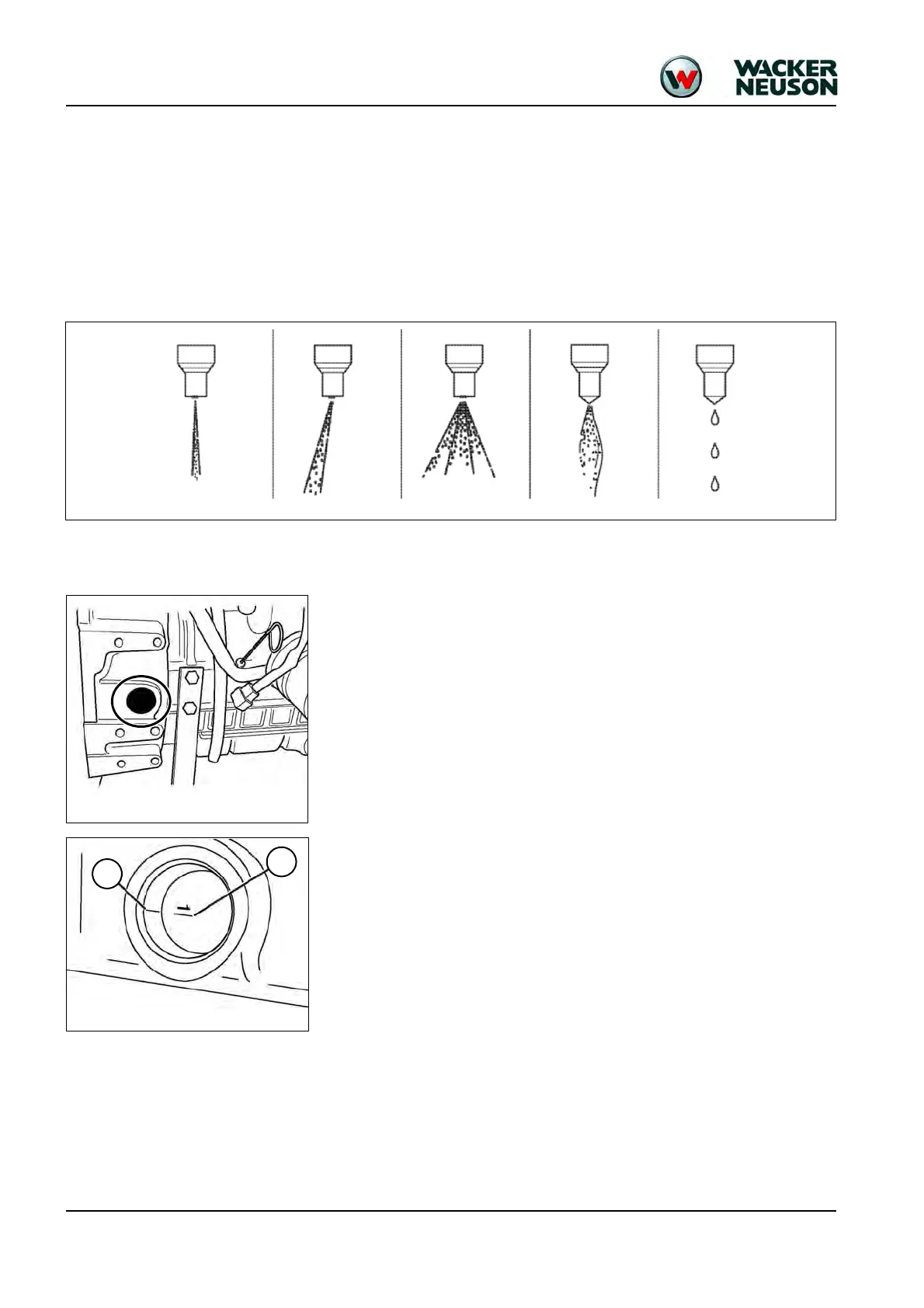

☞Remove the cap on the flywheel housing, see Fig. 27

➥The view to the ring gear is opened.

☞Position a spanner on the screw of the pulley (on the crankshaft) and turn clockwise.

☞Turn until top dead center marks B on the ring gear for cylinder 1 are visible and at the

same level as mark F on the flywheel housing.

➥There are several marks on the ring gear depending on the number of cylinders of

the diesel engine; each individual mark can be used with the corresponding cylinder

for testing purposes.

➥Top dead center can be assigned to the correct cylinder with the number B stamped

next to it.

Normal

-------------------------------------------------Variation-----------------------------------------------

Fig. 27: Flywheel housing cap

Fig. 28: Top dead center mark

F

B

Loading...

Loading...