SHB 803 en – Edition 2.4 * 803s210.fm 2-9

Technical data

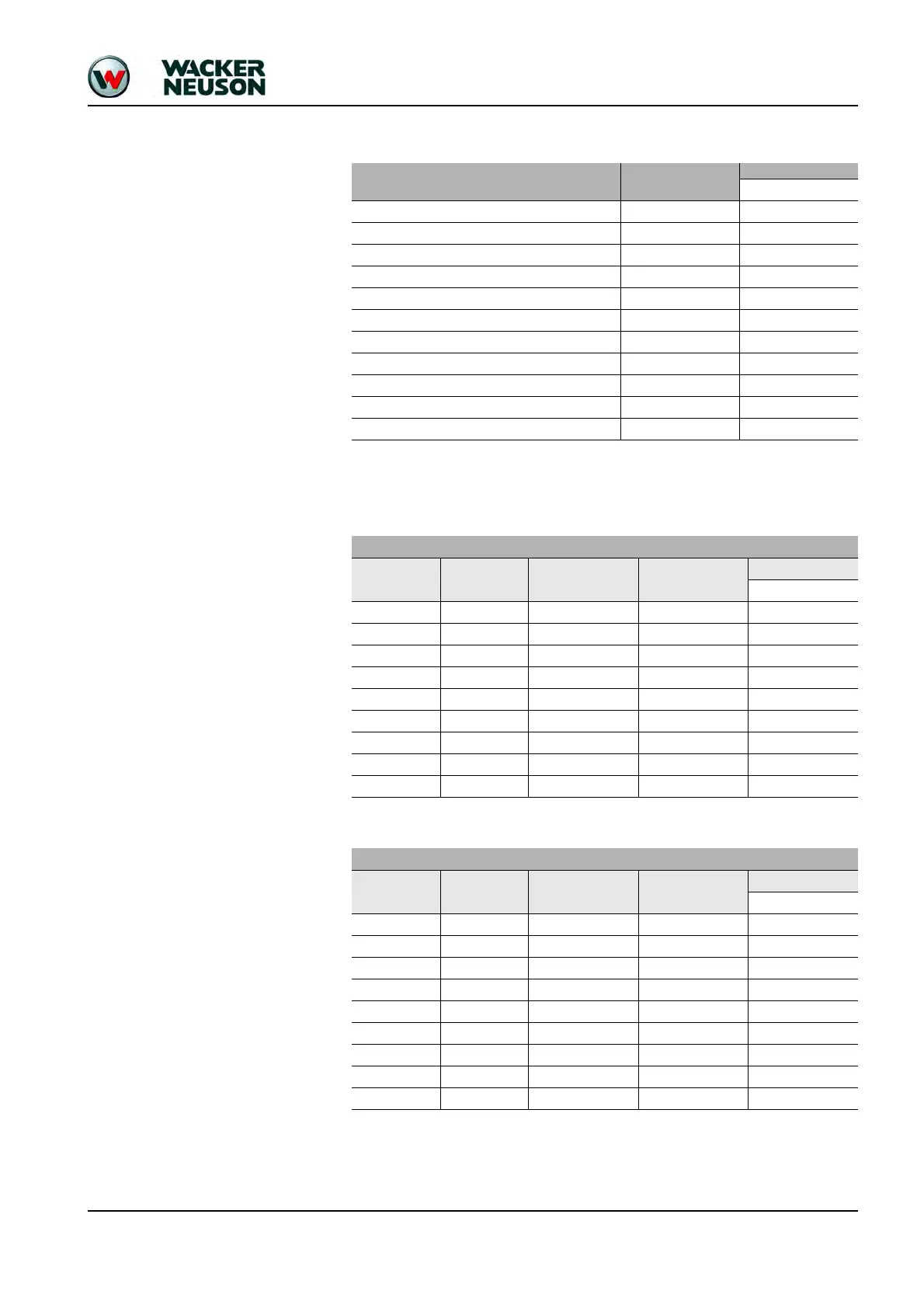

2.10 Model-specific tightening torques

*) All connections with an * must be glued with Loctite S2420 or VaryBond 12-43.

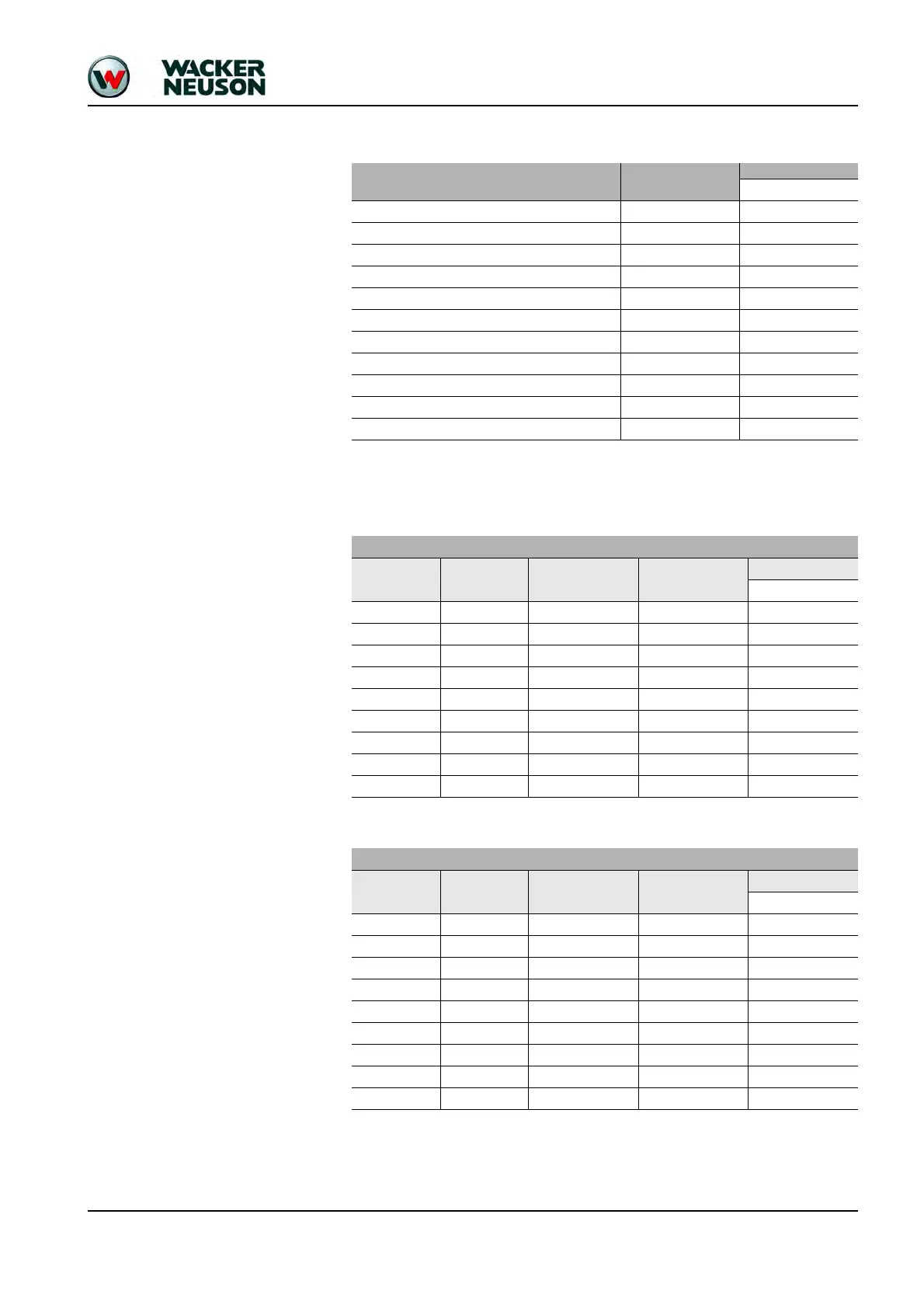

2.11 General tightening torques

Tightening torques for hydraulic threaded fittings (dry assembly)

Galvanized and dry surface (O-ring slightly oiled). Torque tolerance: −10 %

Values determined empirically and to be applied as approximate figures.

Galvanized and dry surface (O-ring slightly oiled). Torque tolerance: −10 %

Values determined empirically and to be applied as approximate figures.

Model 803 Thread

Torque

Nm (ft lbs)

Live ring M12x1.25 10.9 130 (95.9)*

Track roller M10 10.9 65 (47.9)*

Drive pinion M10 10.9 65 (47.9)*

Traveling drive M10 10.9 65 (47.9)*

Gear motor M12 10.9 110 (81.1)*

Angled engine bracket M10 8.8 45 (33.2)

Engine bearing M10 8.8 45 (33.2)

Pump base M10 8.8 45 (33.2)

Pump M10 8.8 45 (33.2)

Swivel joint M10 10.9 64 (47.2)*

Bumper M14 12.9 230 (169.6)*

Metric hose fittings for hydraulic applications (light execution, DKOL)

Nominal Ø Outer Ø Thread Wrench size

Torque

Nm (ft lbs)

05 6L M12X1.5 WS 14 15 (11)

06 8L M14X1.5 WS 17 20 (14.7)

08 10L M16X1.5 WS 19 40 (29.5)

10 12L M18X1.5 WS 22 50 (36.8)

12 15L M22X1.5 WS 27 75 (55.3)

16 18L M26X1.5 WS 32 85 (62.7)

20 22L M30X2 WS 36 100 (73.75)

25 28L M36X2 WS 41 180 (132.7)

32 35L M45X2 WS 55 220 (162.3)

Metric hose fittings for hydraulic applications (heavy execution, DKOL)

Nominal Ø Outer Ø Thread Wrench size

Torque

Nm (ft lbs)

05 8S M16X1.5 WS 19 40 (29.5)

06 10S M18X1.5 WS 22 50 (36.8)

08 12S M20X1.5 WS 24 60 (44.3)

10 14S M22X1.5 WS 27 75 (55.3)

12 16S M24X1.5 WS 30 90 (66.4)

16 20S M30X2 WS 36 100 (73.8)

20 25S M36X2 WS 41 180 (132.8)

25 30S M42X2 WS 50 270 (199.1)

32 38S M52X2 WS 60 400 (295)

Loading...

Loading...