SHB 803 en – Edition 2.4 * 803s410.fm 4-23

Engine

4.21 Checking the injection nozzles

Pressure check

☞Ball-type cock on fuel filter in the “OFF” position.

☞Clean the area around the nozzles and the injection pump.

☞Remove the injection line and the injection nozzle.

☞Connect the injection nozzle to the nozzle tester by means of a suitable adapter.

☞Slowly increase pressure until the nozzle ejects fuel and read the pressure off the pres-

sure gage.

☞If the injection pressure is too low, replace the spacer in the nozzle by a thicker one. If

the pressure is too high, replace the spacer by a thinner one.

➥Injection pressure: 118 – 128 bar (1711 – 1856 psi).

• Spacer thickness of 0.1 mm (0.004") corresponds to modification by 6.9 – 9.8 bar (100

– 142 psi).

☞Perform another check.

☞Check the injection nozzle for drips after it has ejected fuel.

☞Increase pressure up to shortly below the injection pressure during 5 seconds, and

check whether fuel drips from the nozzle.

☞Install the nozzle.

☞Open the ball-type cock on the fuel filter again.

☞Start the engine and check the system for leaks.

Use a suitable container to collect fluids and lubricants as they flow out and

dispose of them in an environmentally friendly manner.

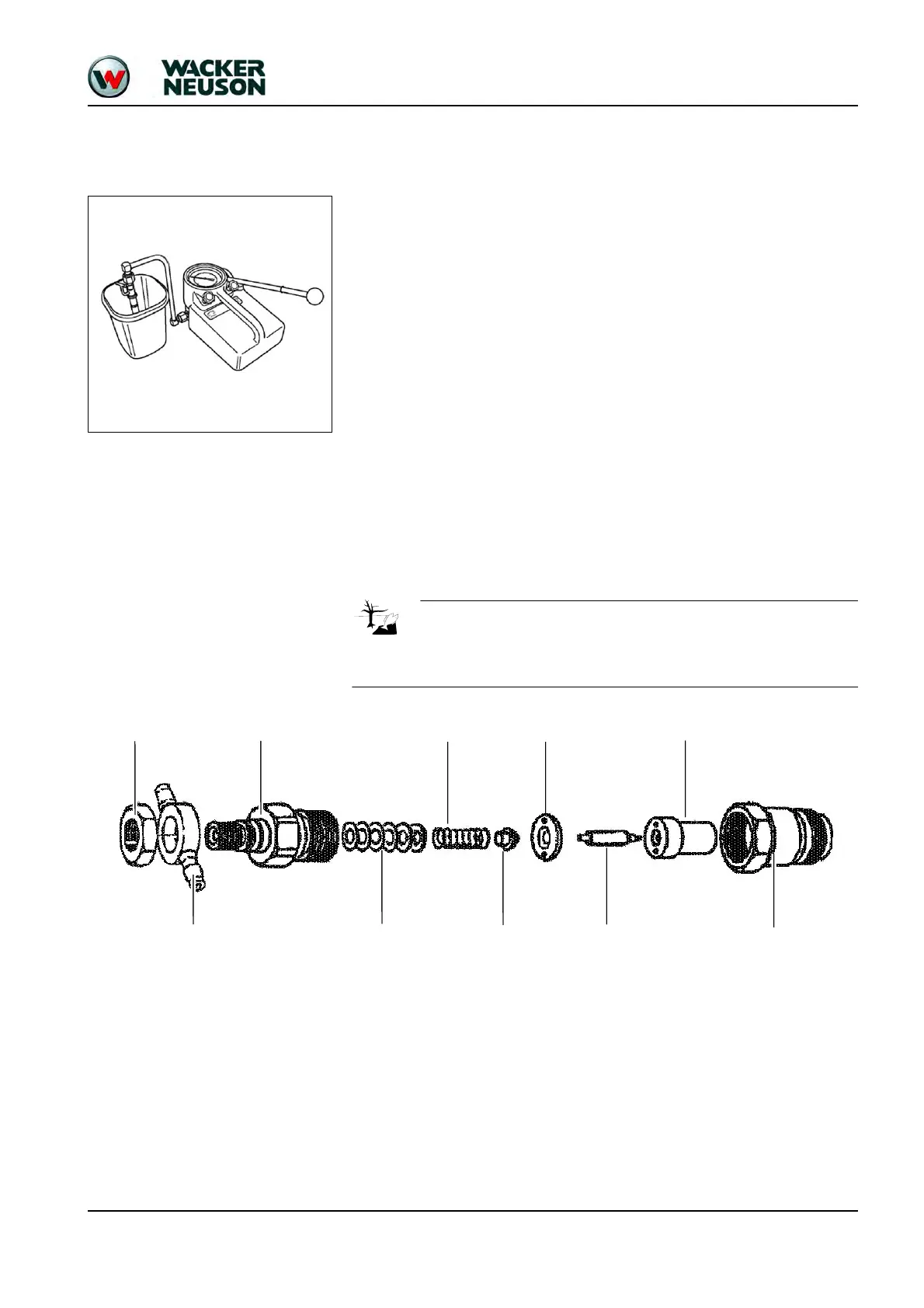

Threaded fitting

Pressure spacers

Valve thrust washer

Spring seat

Nozzle body

Lower nozzle screw fitting

Spring

Fuel return connection

Upper nozzle housing

Nozzle valve

Loading...

Loading...