Sawmill Alignment

Routine Alignment Procedure

7

7-4 60HDdoc102619 Sawmill Alignment

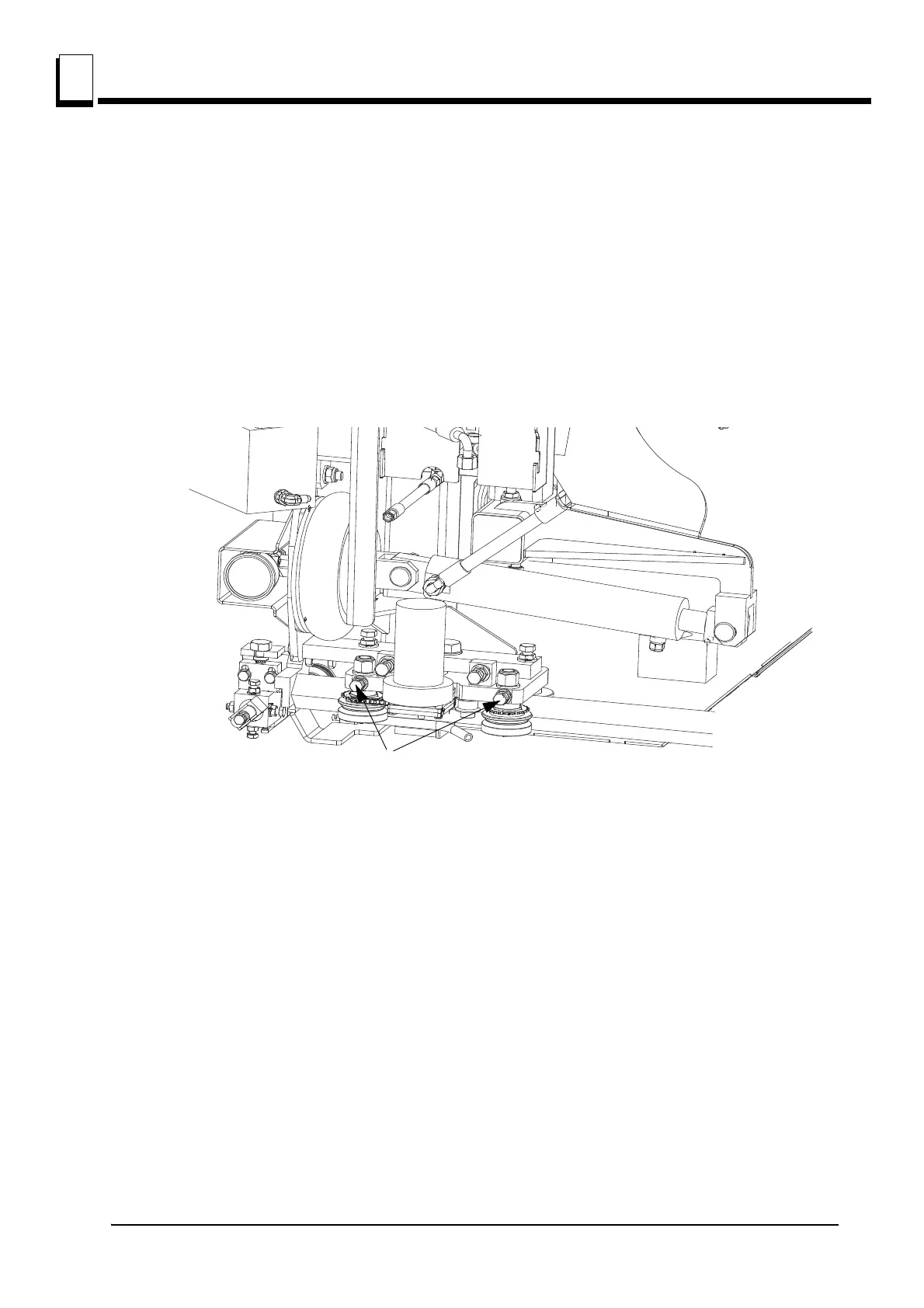

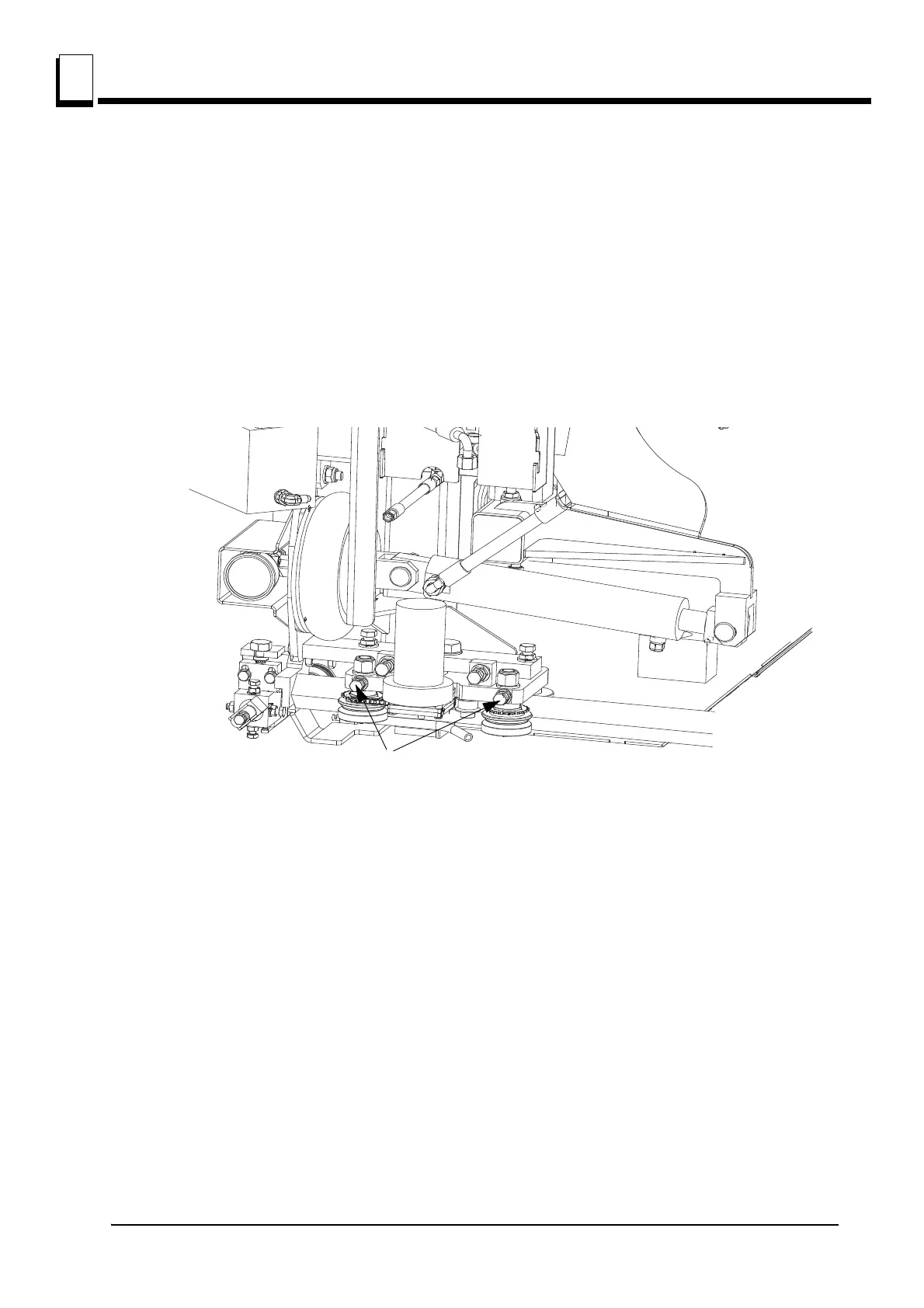

Blade Guide Arm Alignment

The blade guide arm moves the outer blade guide in and out. If the arm becomes loose, the blade

guide will not deflect the blade properly, causing inaccurate cuts. A loose blade guide arm can also

cause blade vibration.

1. Adjust the blade guide arm in to 1/2" (15 mm) from fully closed.

2. Manually try to move the arm up and down. If you can move the arm by hand, you will need to tighten

the arm rollers.

See Figure 7-3. Loosen the jam nuts and turn the adjustment bolts in to tighten the blade guide arm

rollers. Retighten the jam nuts.

After tightening the blade guide arm rollers, check that the arm is aligned properly.

Blade Guides

3. With the arm adjusted 1/2" (15 mm) from fully closed, measure the distance between the blade guide

roller flange and the back of the blade. If the sawmill is equipped with optional all-ceramic guides,

measure from the back of the blade to the back roller.

FIG. 7-3

Loading...

Loading...