B95W

Maintenance

130 / 306

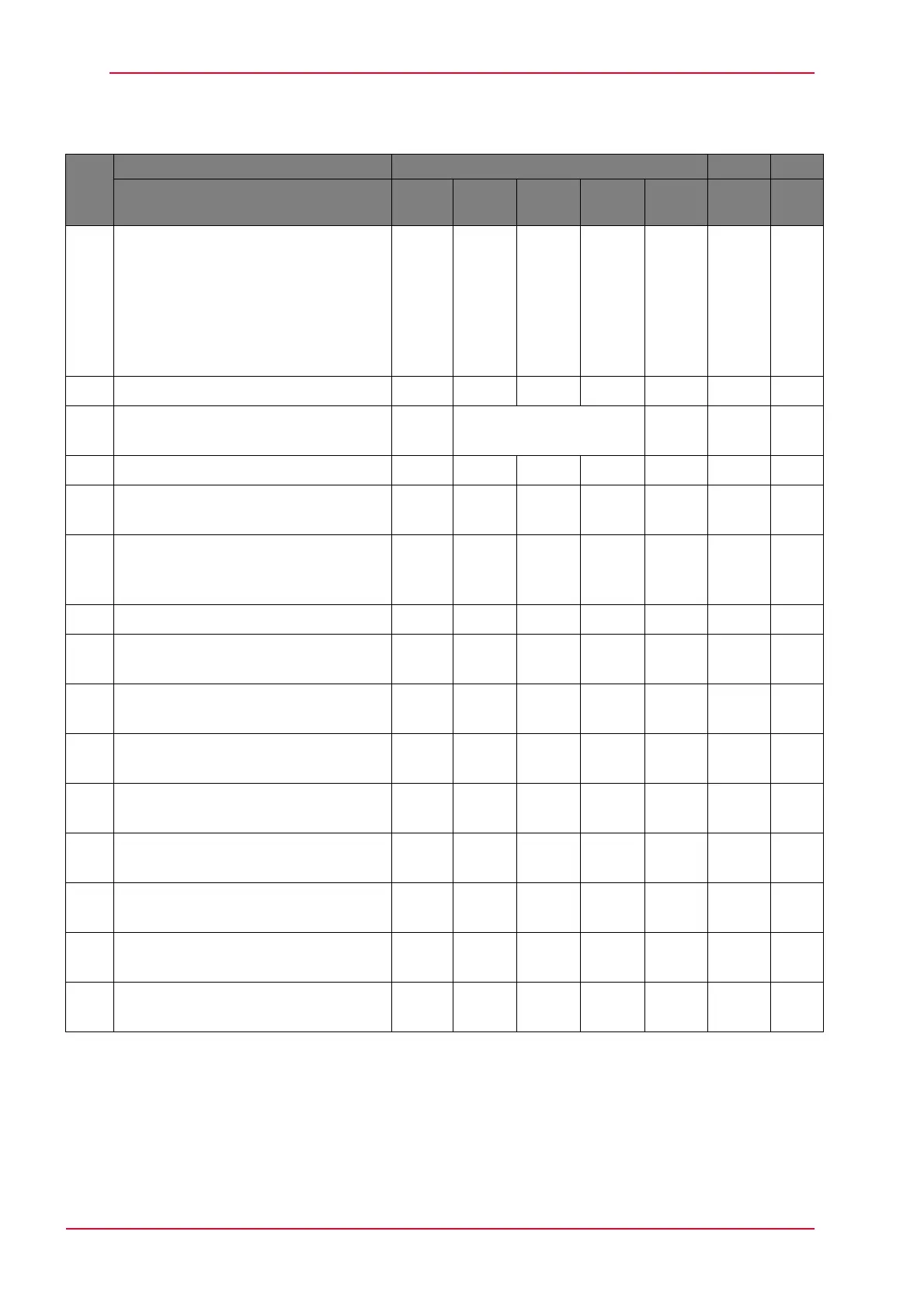

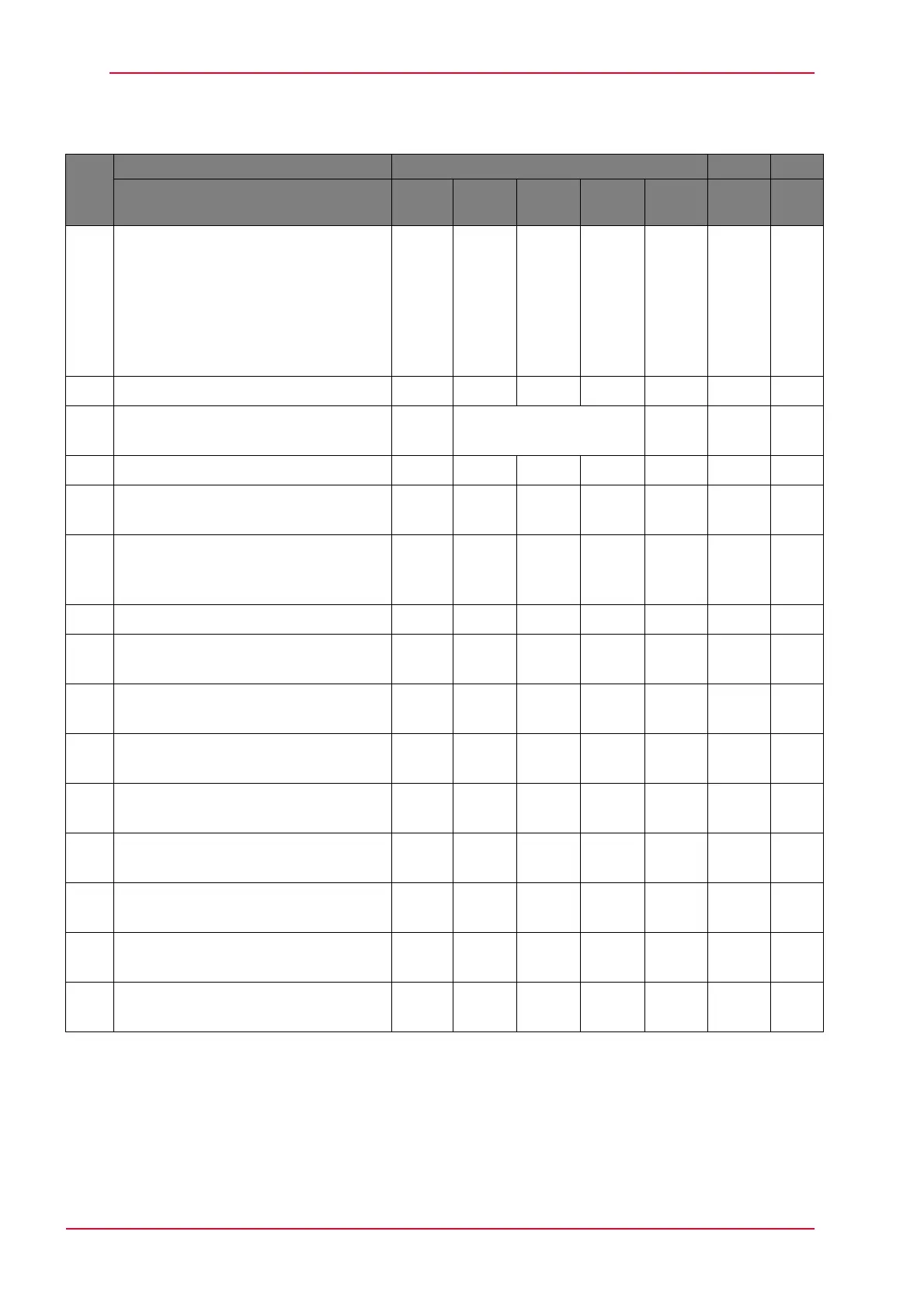

6

06_Wartung und Pflege_en.fm - V1.0 - 1.8.17

20

33 Check tightness of all pipes, hoses,

control valves, hydraulic pumps,

cylinders, etc.

The screw-in couplings must be

locked when tightening hose or

line connectors to prevent them

from turning

oo --

34 Check or change hydraulic oil o o x

4)6)

166

35 Replace insert of hydraulic oil return

suction filter

x

according to the

maintenance indicator

x 171

36 Replace ventilation filter x x 199

37 Check that the slewing ring fastening

screws are seated securely

o o 188

38 Check that the swing-gear

attachment (hydraulic motor and

transmission) is secure

o o 188

39 Check slew gear brake functioning o o

40 Check function of brakes and brake

disc play

o o 183

41 Differential – rear axle oil: check or

oil change resp.

x x x 177

42 Differential – front axle oil: check or

oil change resp.

x x x 177

43 Transmission on front axle; check

or change oil

x x x 179

44 Wheel hubs of front and rear axles;

oil check or oil change

x x x 180

45 Lubricate the machine according to

the lubricating chart

o o 122

46 Check function, condition and

completeness of safety equipment

oo --

47 Hydraulic function check with

pressure test of functions

oo --

No. Inspection Hours in operation

Page

o = Check, maintenance

x = Replace

After

100

every

500

every

1000

every

3000

at least

2 x year

at least

1 x year

Loading...

Loading...