AO2000 CONTINUOUS GAS ANALYZERS | OI/AO2000-EN REV. B 213

Calibration: Principles

Calibration control

Calibration control

Depending on the gas analyzer version and equipment, there are three

methods for controlling calibration:

• Manual calibration

• Automatic calibration

• Externally controlled calibration

All analyzer modules can be calibrated using any of the three methods.

Calibration start

• Manual calibration is started manually via the gas analyzer’s display and

control unit.

• Automatic calibration is started at time intervals determined by the

internal clock or by an external control signal or manually via the gas an-

alyzer’s display and control unit.

• Externally controlled calibration is triggered by an external control signal.

Wait until the warm-up phase has ended

Calibration should only be started after the warm-up phase.

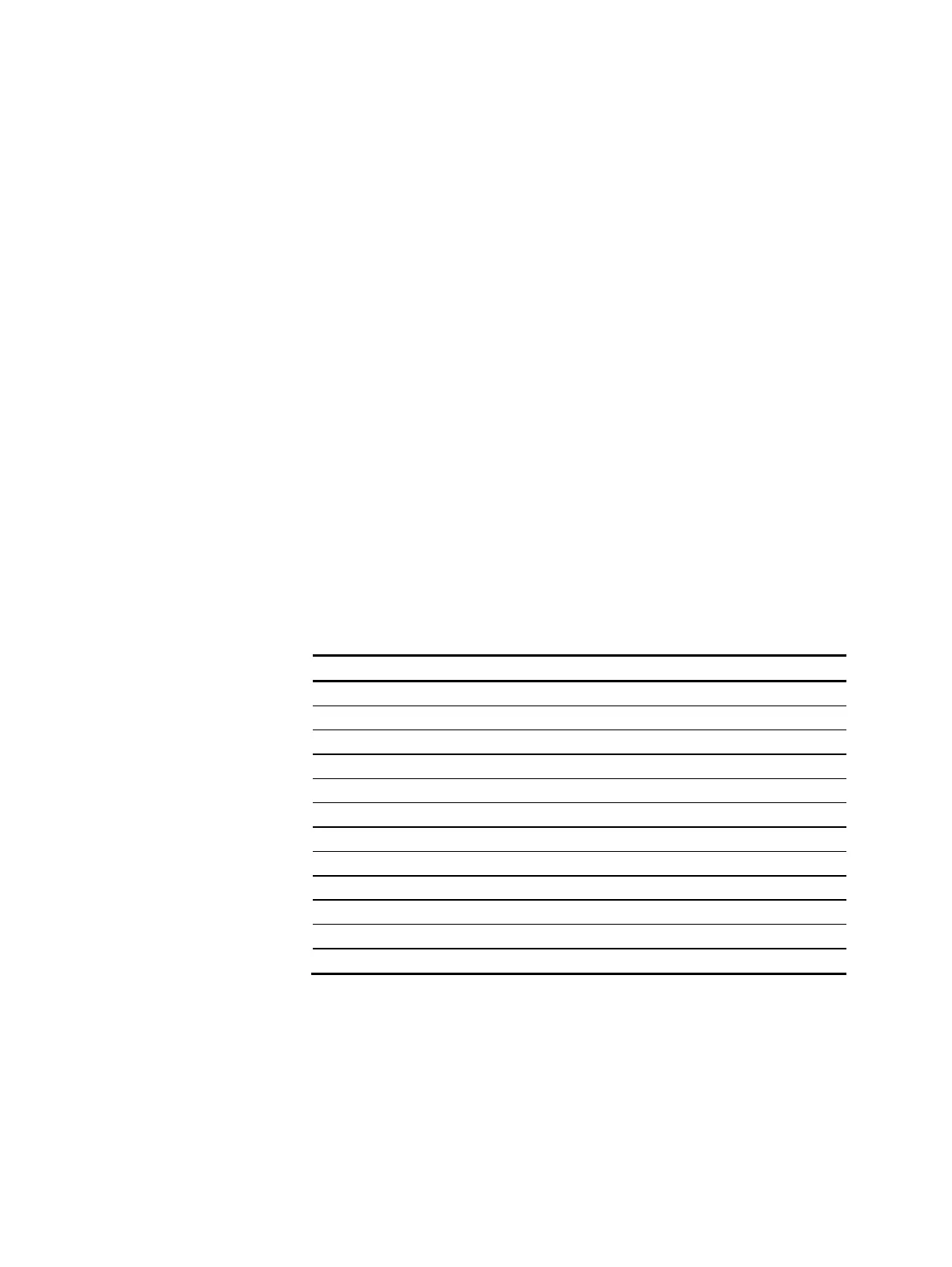

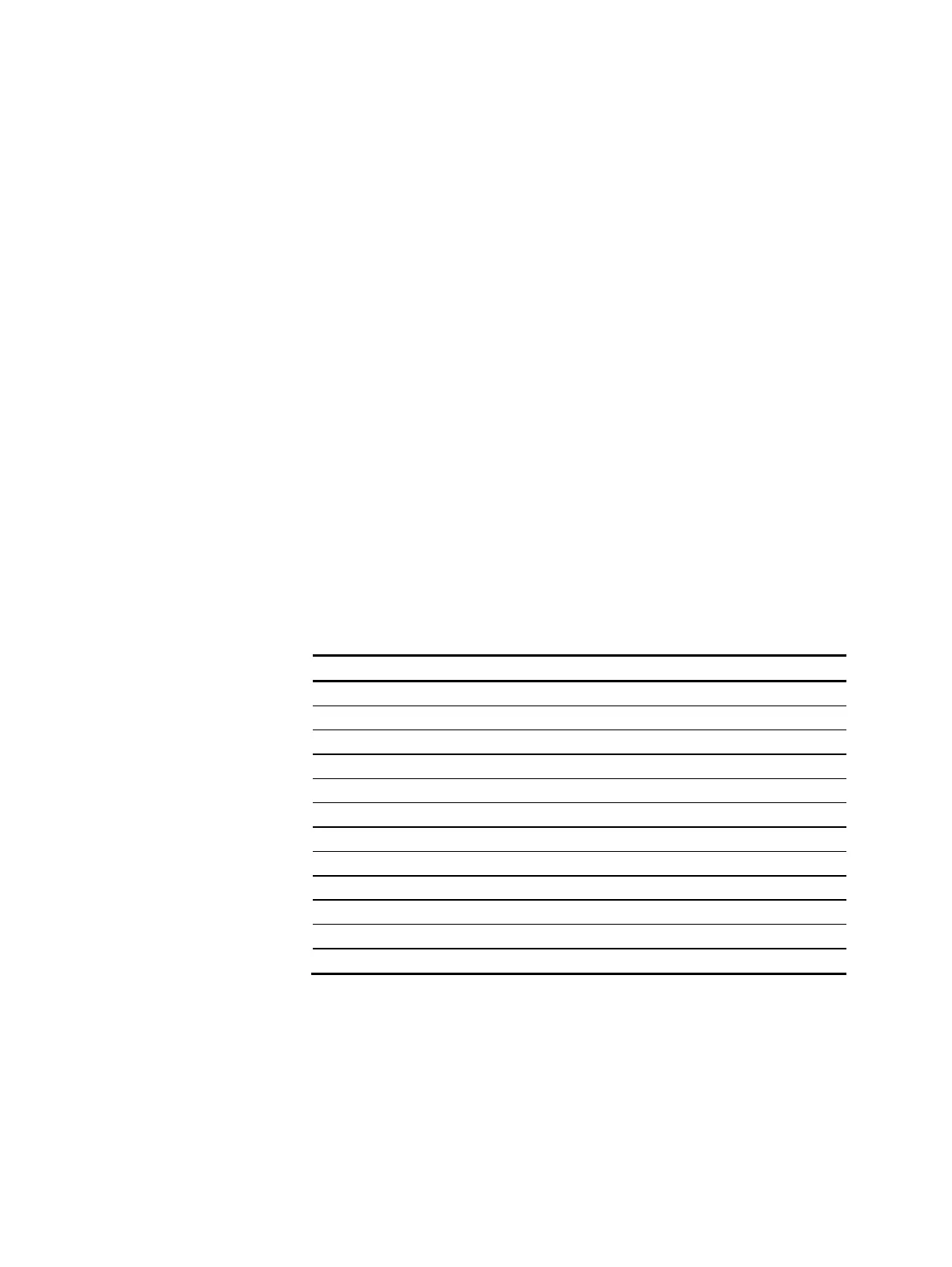

Analyzer module Duration of the warm-up phase

Caldos25 1.5 hours

Caldos27 30/60 minutes for class 1/2 measurement ranges

1)

Fidas24 ≤ 2 hours

Fidas24 NMHC ≤ 2 hours

Limas11 IR Approx. 2.5 hours

Limas21 UV Approx. 2.5 hours

Limas21 HW Approx. 4 hours

Magnos206 ≤ 1 hour

Magnos28 ≤ 1 hour

Magnos27 2 to 4 hours

Uras26 Approx. 0.5/2 hours without/with thermostat

ZO23 Approx. 15 minutes

1) See "AO2000 Series" data sheet for class details.

Plausibility check during the calibration

If during calibration the gas analyzer finds implausible values (e.g. if the

span and zero values are equal), calibration is stopped and an error message

is generated. The values stored for the last calibration remain in effect.

Status signal

The "Maintenance mode" status signal is set during calibration.

Loading...

Loading...