2/11

A 200

About leak detection

GB 03302 - Edition 03 - July 12

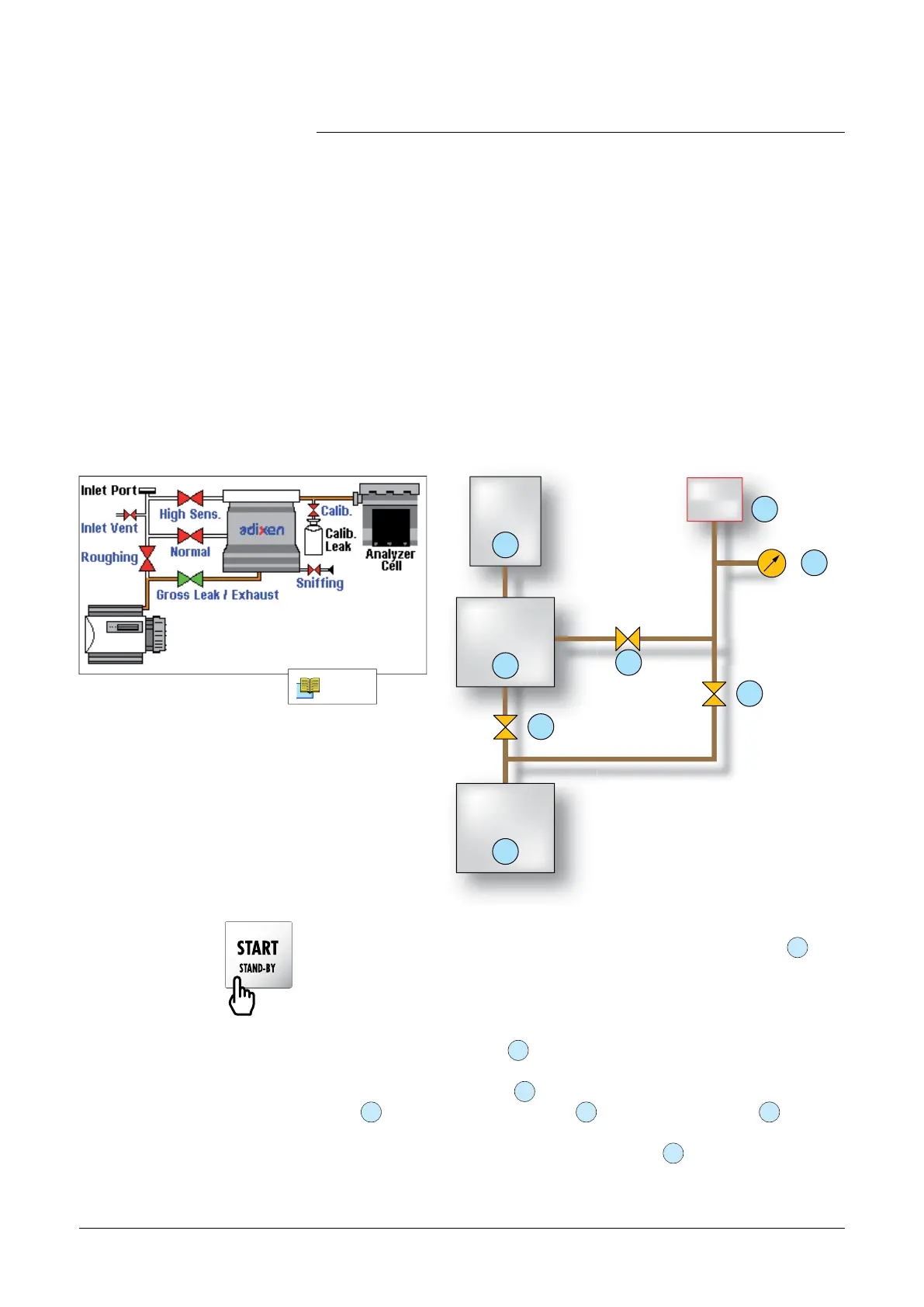

The general vacuum diagram of the leak detector is shown below.

A dynamic version of the vacuum diagram is available on the leak

detector display panel. Green valves indicate opened valves. Red

valves indicate closed valves.

Vacuum circuit of a

leak detector

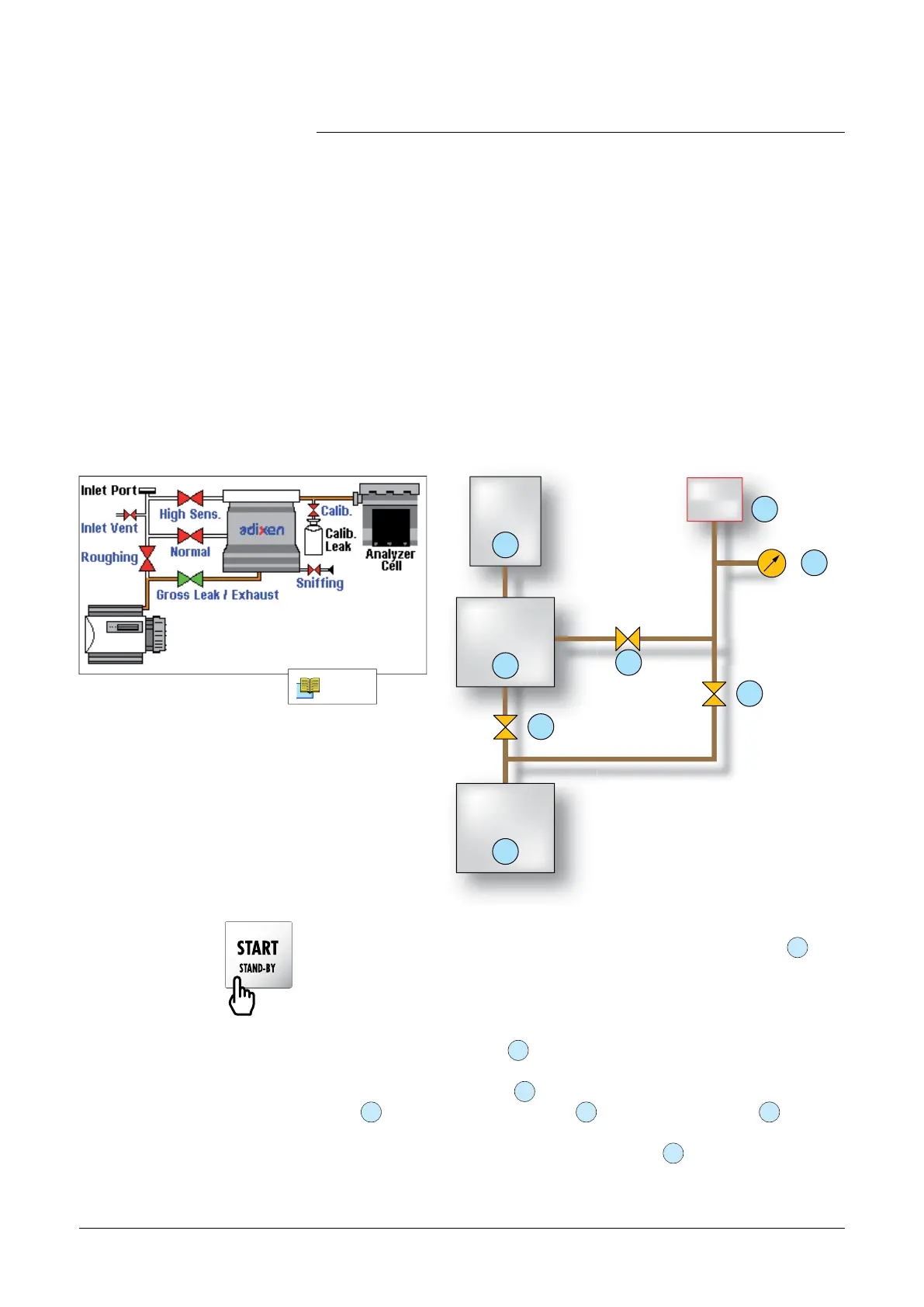

Test Procedure:

n Connect the part to be tested at the inlet of the leak detector

1

,

then press the [START/Stand by] key.

When the unit is not in test mode (stand-by or roughing mode), the

helium displayed corresponds to the internal helium background of the

unit.

n Roughing Mode: Valve

3

opens and the primary pump evacuates

the inlet of the unit as well as the part connected to it.

n When the inlet pressure

2

reaches the test cross over, the roughing

valve

3

closes, the exhaust valve

6

opens, the test valve

4

opens.

The high vacuum is then connected to the inlet of the leak detector

taking care of the gas load. The analyzer cell

8

will measure any

helium present. The value of the leak will be measured and displayed

on the control panel.

analyzer

cell

tested

part

8

6

secondary

pumping

exhaut

valve

7

primary

pumping

5

3

4

1

2

roughing

valve

test

valve

inlet pressure

gauge

inlet

C 200

General vacuum circuit

of a leak detector

Vacuum circuit of

the ASM 310

adixen Vacuum Products - ASM 310 Operating instructions

Loading...

Loading...