6/11

A 200

About leak detection

GB 03302 - Edition 03 - July 12

He

He

START

STAND-BY

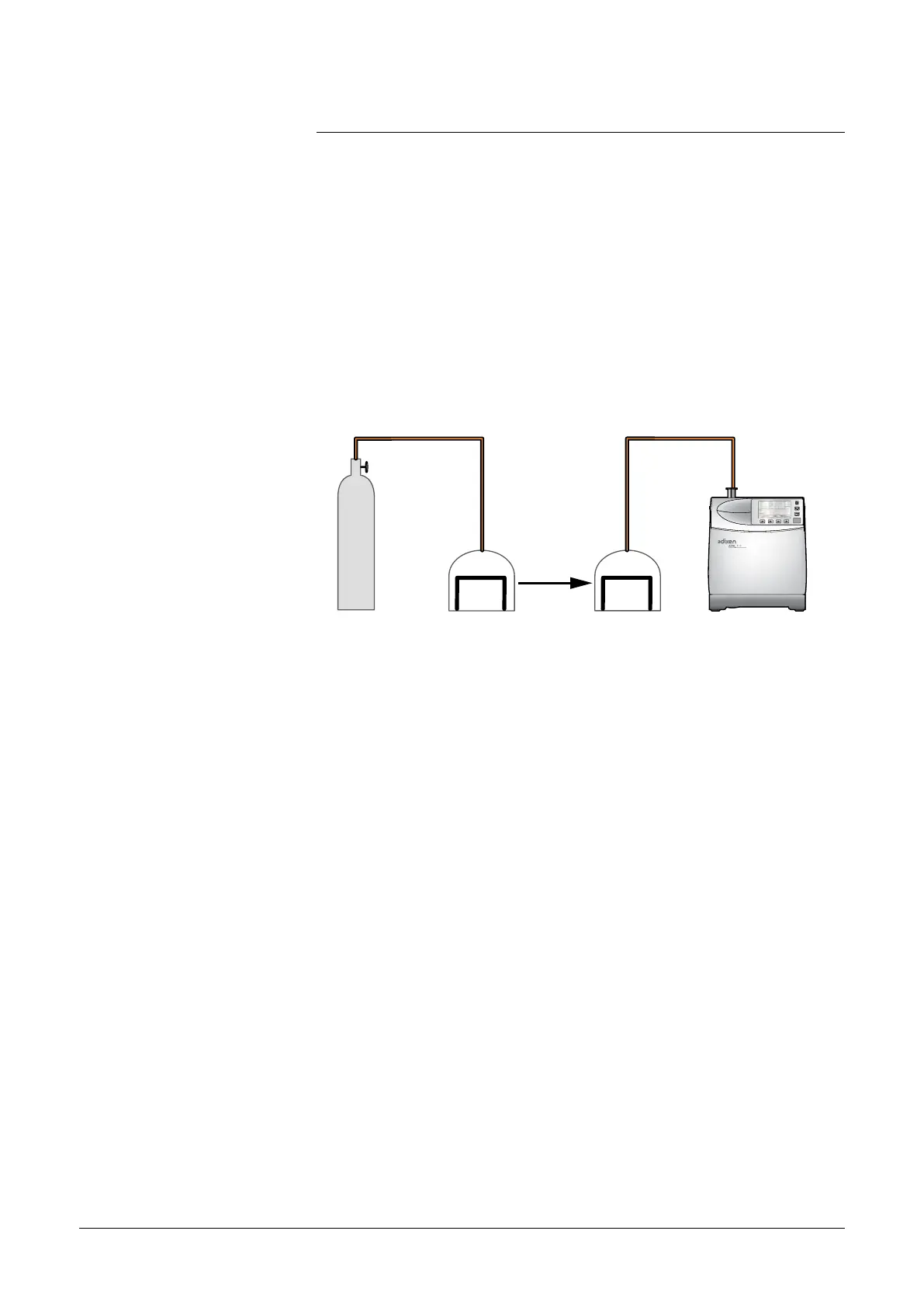

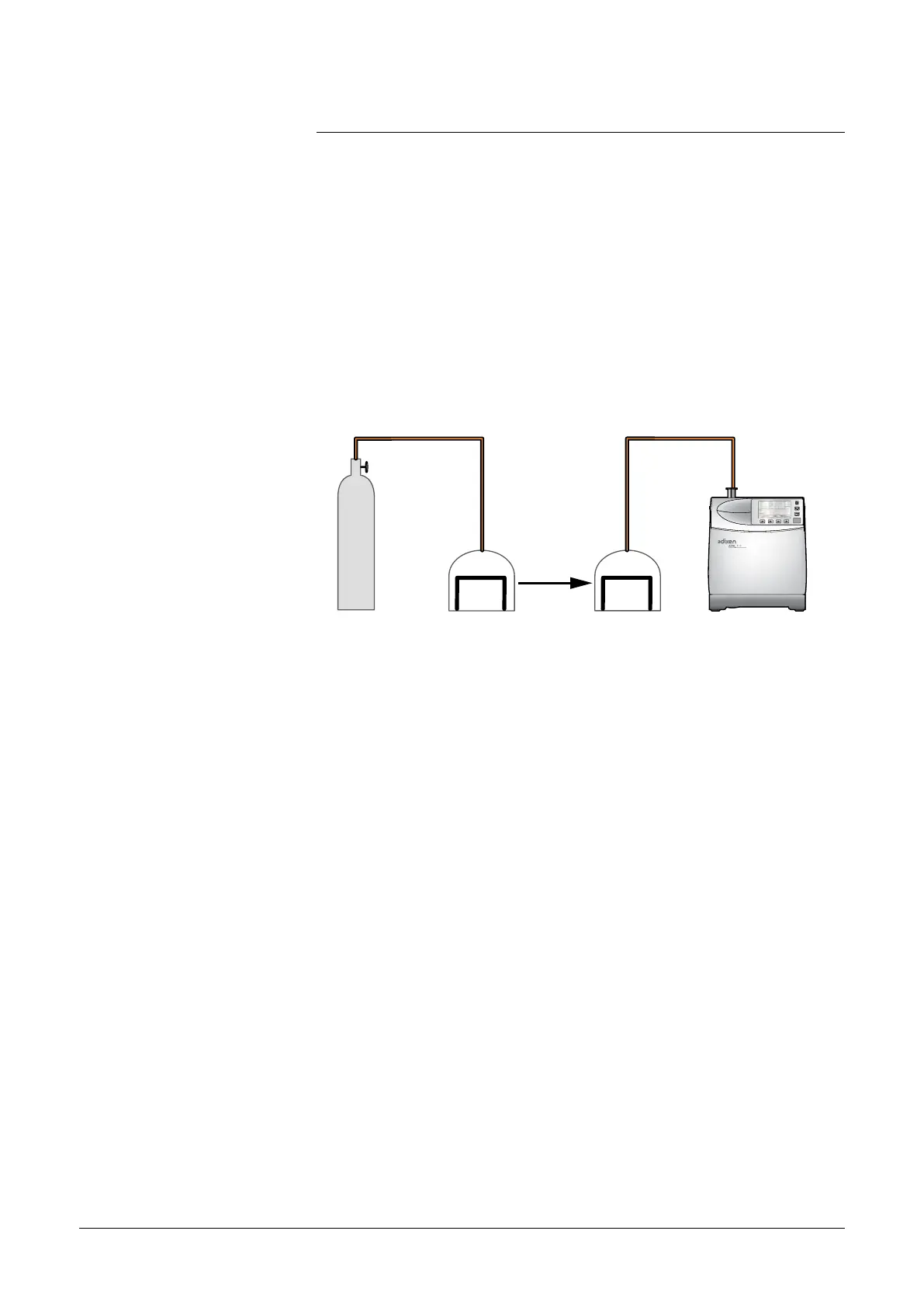

The part is placed in a chamber containing pressurized helium.

The helium penetrates the part if it has a leak.

The part is then removed from the chamber and placed in another

vacuum chamber which is connected to the detector. The helium

escapes from the part through the leak and produces a signal.

This signal is not a direct measurement of the leak as the helium

pressure inside the part is difficult to determine. Several parts play an

important part such as: the pressurization time, the helium bombing

pressure, the internal volume, the aeration time, the size of the leak.

Please consult us for details about this method.

Bombing method

This method is used for sealed objects that cannot be connected

directly to the detector (semiconductors, waterproof watches, etc.).

The "MIL-STD-883- Method 1014" standard allows to comprehend

parameters of this test. Before this test, it is necessary to do a gross

leak test to remove parts with a very gross leak.

part part

Chamber 1

Chamber 2

detector

adixen Vacuum Products - ASM 310 Operating instructions

Loading...

Loading...