4/11

A 200

About leak detection

GB 03302 - Edition 03 - July 12

He

He

START

STAND-BY

START

STAND-BY

Spray method

Response time

When spraying starts, the leak signal is not displayed instantaneously

on the analyzer cell:

there is a response time which depends on the volume V being tested

and the helium pumping speed S of the system at the opening of the

part, according to the following relation:

T = V/S (T in second, V in litre, S in l/s)

T is the time required for the signal to reach 63 % of the final value.

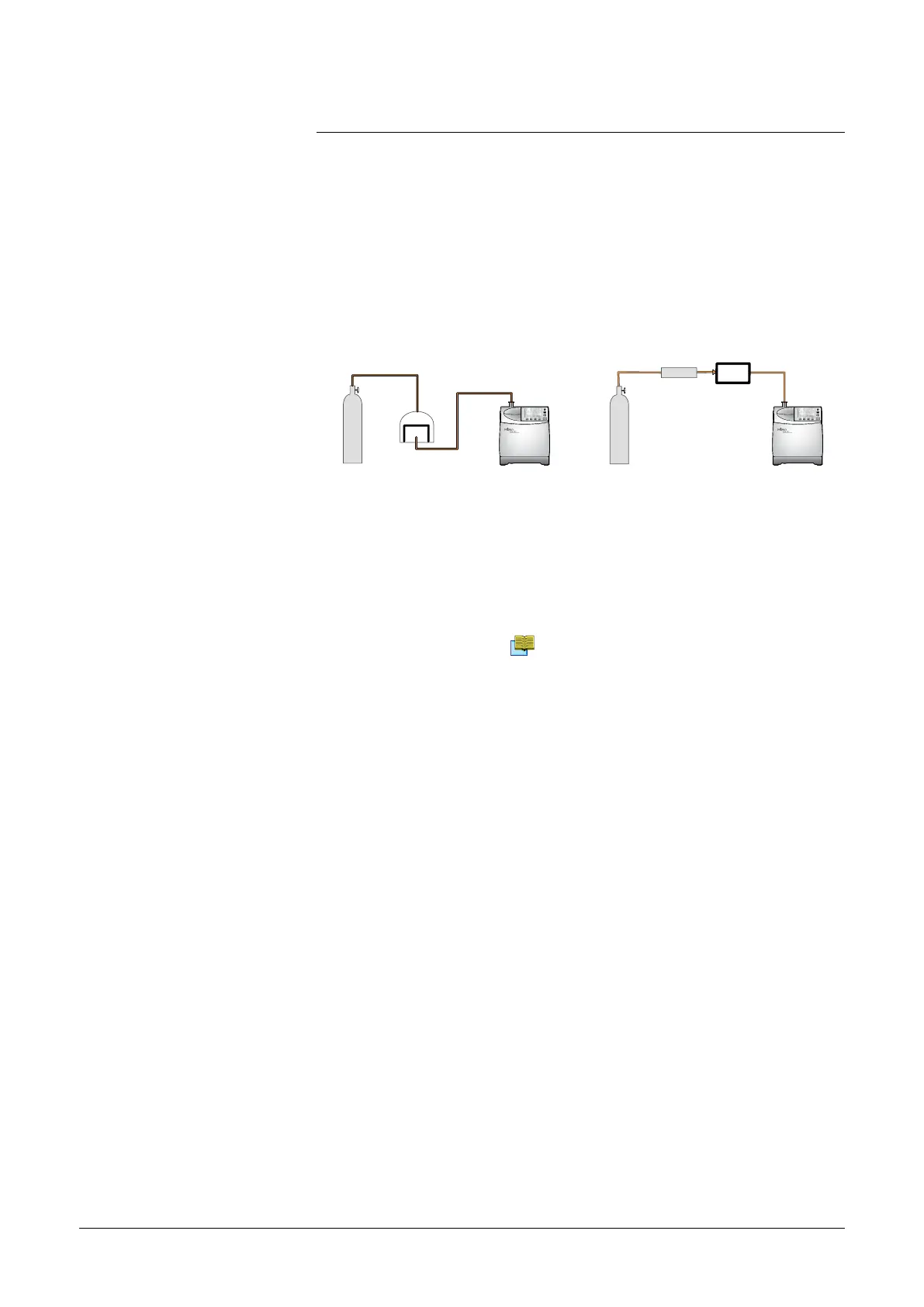

This involves removing air from the part tested, connecting it to the

analyzer cell and then spraying helium over the outer surface.

The part is placed under a

cover, into which helium is

injected.

The leak cannot be located.

Potential leaking areas are

sprayed with helium.

The leak can be located.

Global test

part

spray probe

detector

Spray test

The detector measures the flow of helium penetrating the part.

Connection rules: refer to

B 300

or

part

detector

adixen Vacuum Products - ASM 310 Operating instructions

Loading...

Loading...