307

HARVEST

HARVEST MONITORING/MAPPING

HARVEST

HARVEST

HARVEST MONITORING/MAPPING

DISPLAY PREPARATION

• Create a backup of your spring information. Go to the Setup/Display menu to create a backup. Select Copy

All Files to save the spring data to the USB Flash Drive.

• Make sure your display firmware and all connected modules are up to date.

• If you have purchased a new combine or new heads, create new configurations for any setup that is

different from last fall. Remove all old configurations.

VEHICLE INSPECTION

• Check to make sure all cables are properly attached and in good condition.

• Remove flow sensor and inspect for damage.

• Check the elevator deflector and impact plate for wear. Verify you have the proper clearance at the top of

the clean grain elevator. Clearance should be between 3/8” and 5/8” (0.95 cm to 1.59 cm).

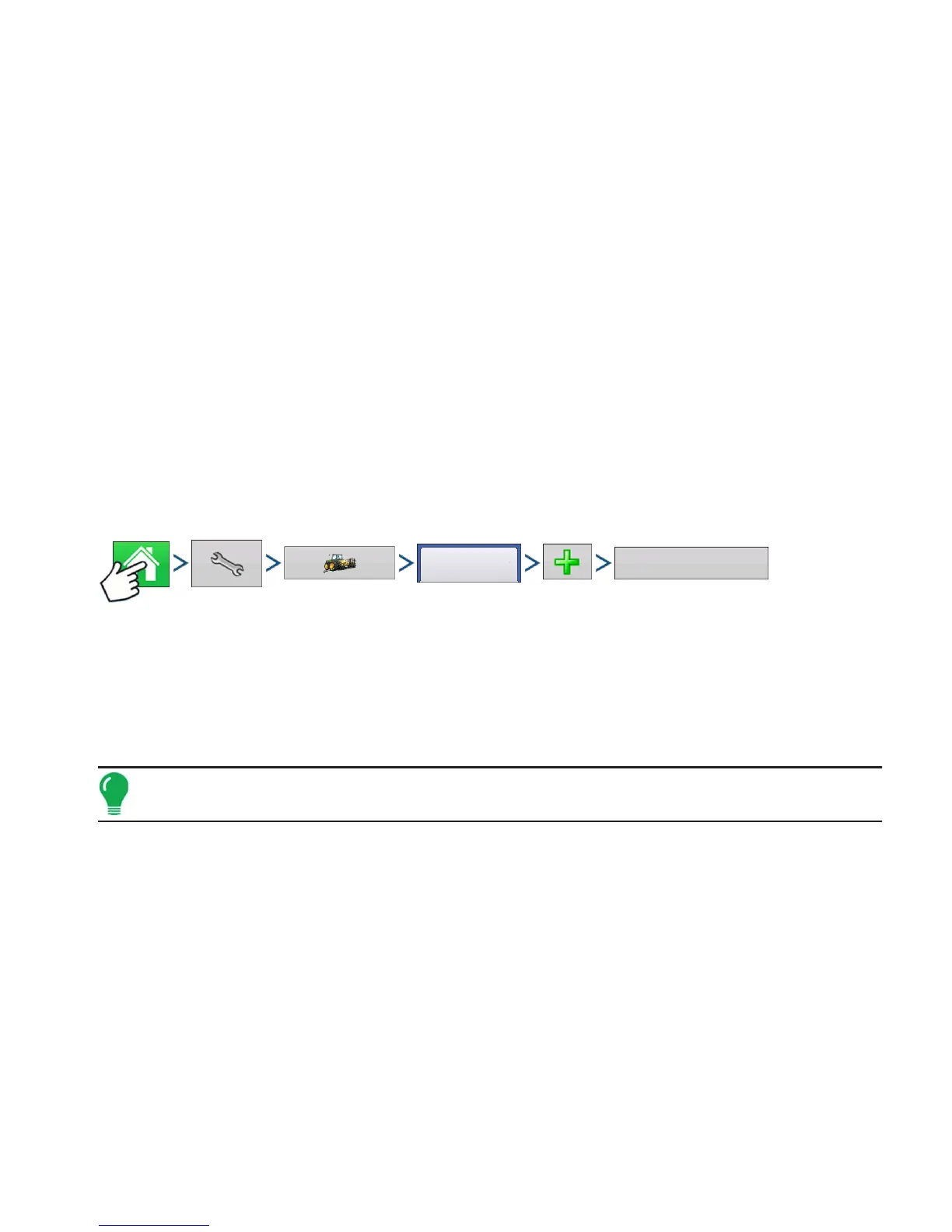

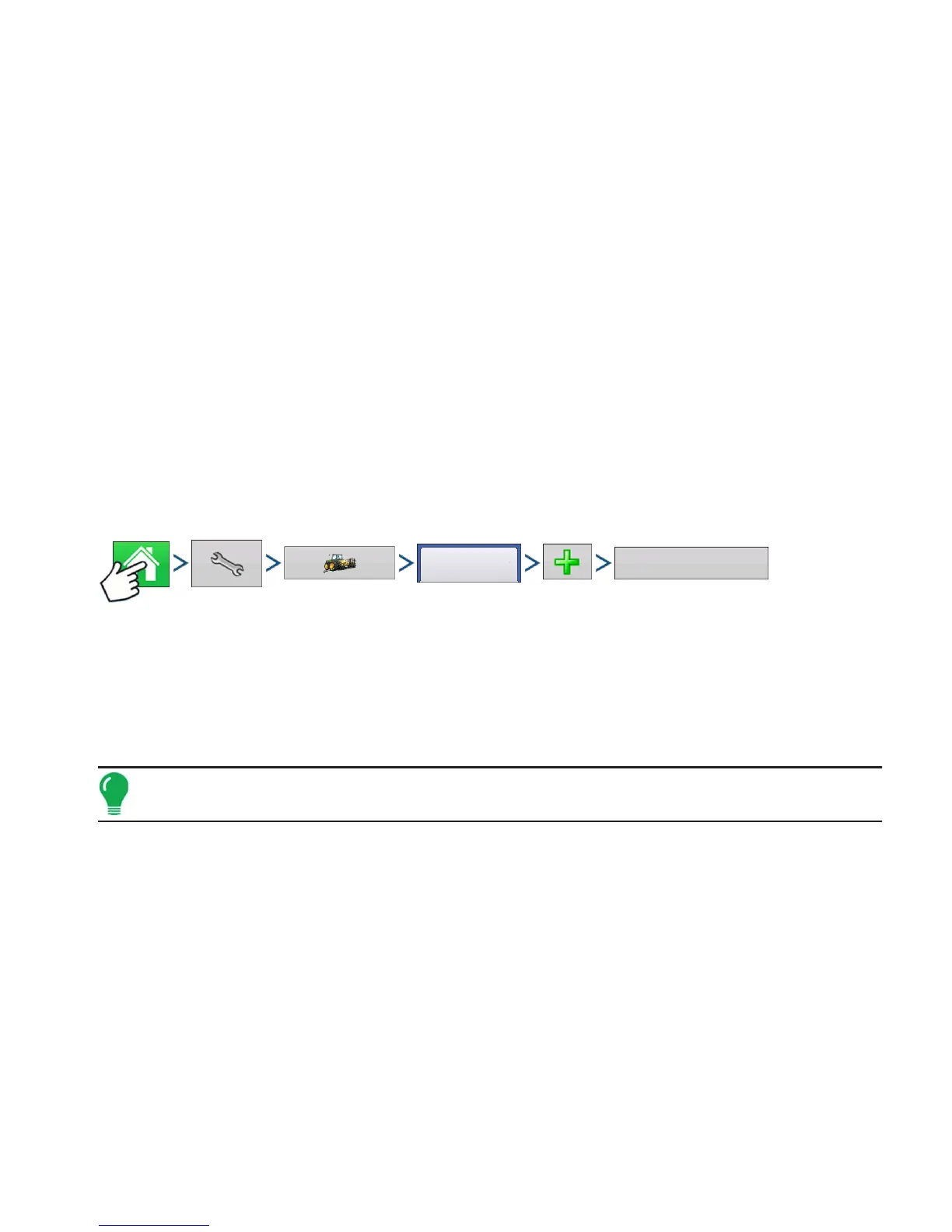

CREATE CONFIGURATION

Press: Home button > Setup (wrench) button > Configuration (tractor) button > Configuration tab > Add

(+) button > Harvest button

A wizard will guide you through the process of selecting or creating a configuration that includes

Combine, Header and Crops settings.

Your Operating Configuration will then be viewable when you start a new Field Operation with the Field

Operation Wizard. For more information on Field Operation Configurations, see “Setup Event” on page 49.

Note: You can also use the Manage Equipment button to create or edit specific vehicles and implements.

CONFIGURATION SETUP

Calibration Sequence

Perform Harvest Calibrations in the following order:

1. Distance (Speed Sensor) Calibration

This calibrates the Ground Speed Sensor connected to the display. (calibrate a backup sensor even when

using GPS speed as the primary speed sensor). For more information, see

“Calibrate Distance” on page 81

.

2. Calibrate Header Sensor

This sets the height when the display stops recording area as the header is raised at the end of the pass.

Stop height calibration is required for each grain type.

Configuration

Harvest

Loading...

Loading...