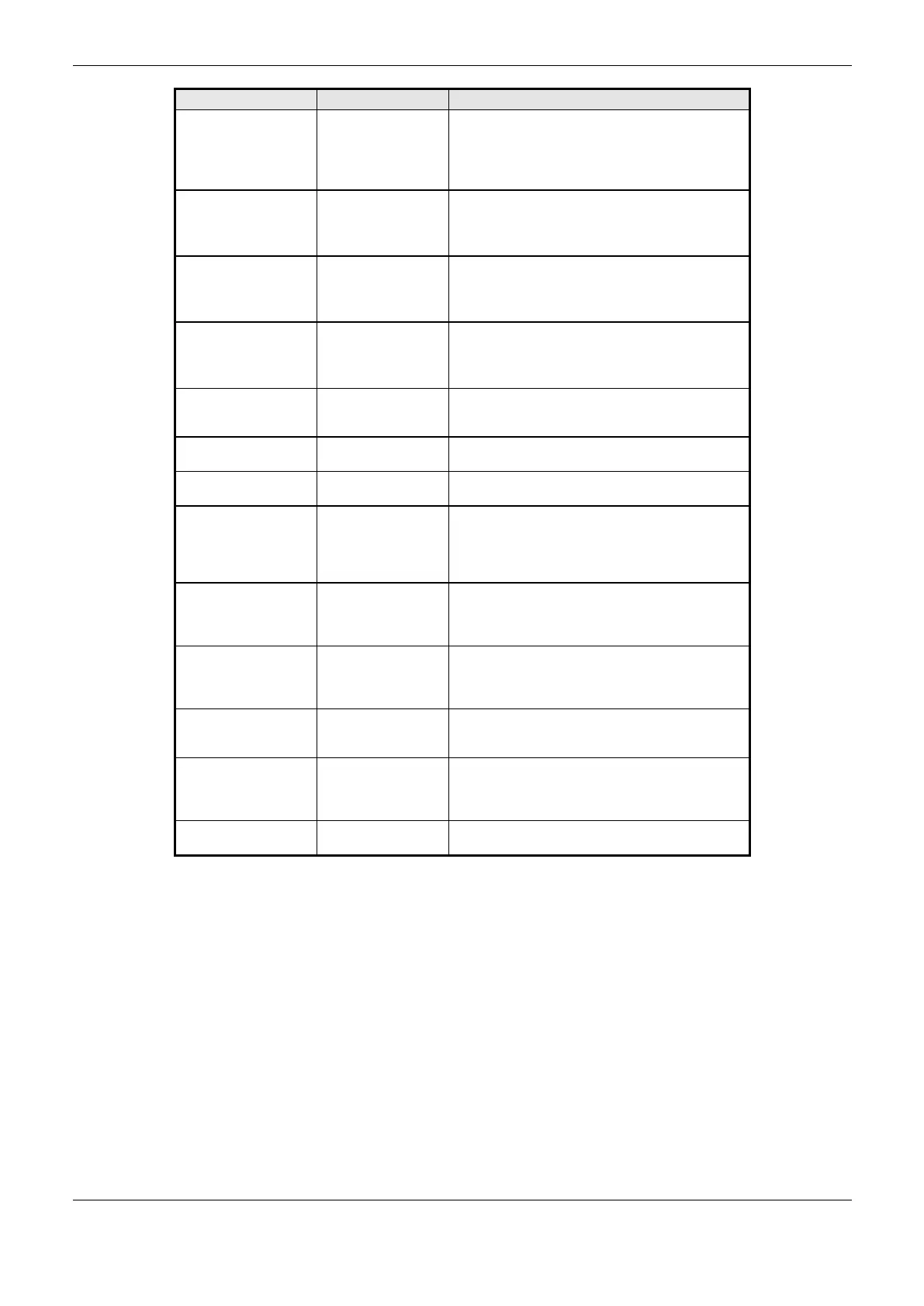

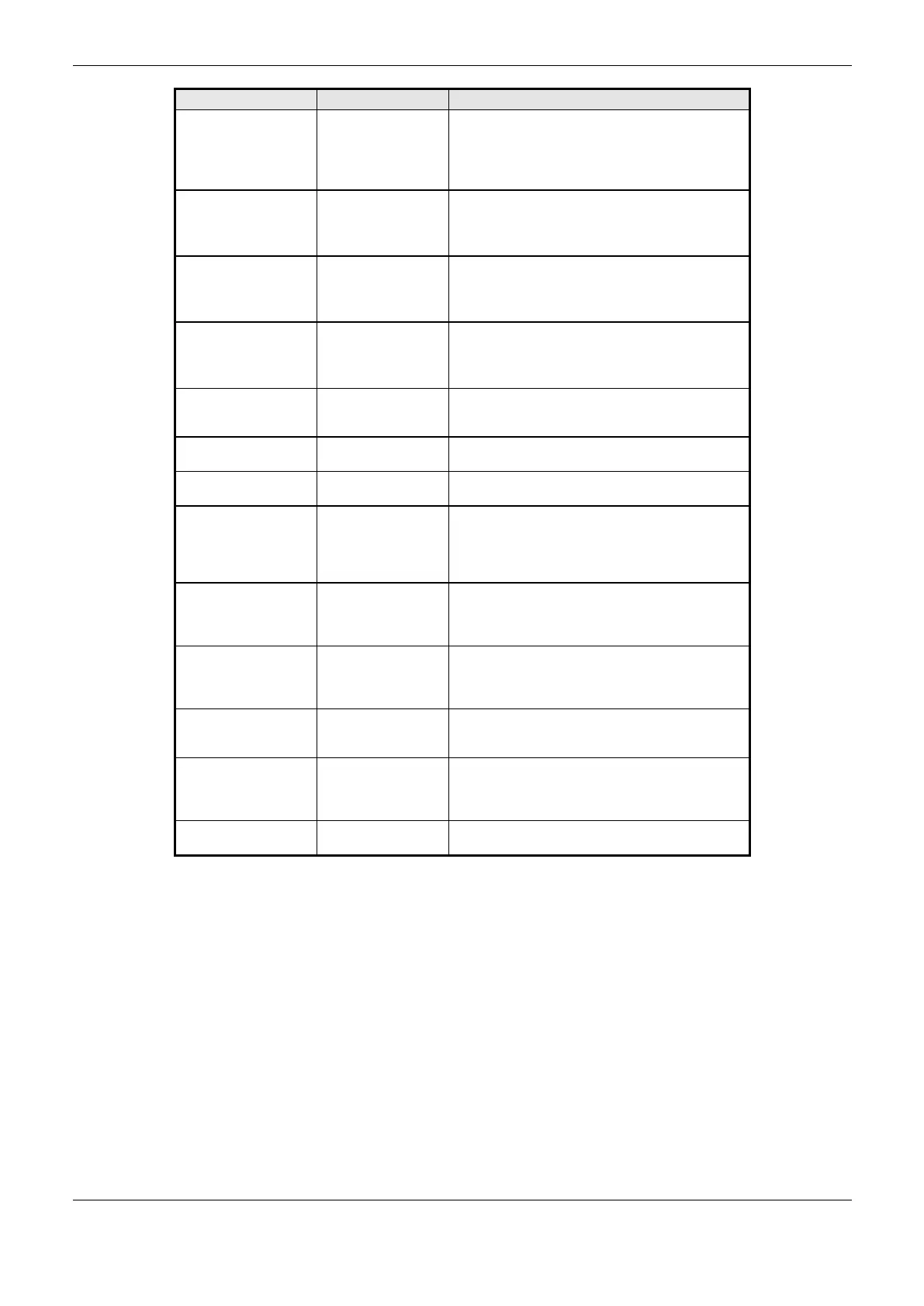

4. Configuration

211

Dead band.

Minimum error value able to generate a MV

correction in automatic mode, in other words, little

errors (smaller than the DeadBand) won’t cause any

variation in the defined variable.

Process variable maximum value.

In case the PV value is higher than the configured,

the PID block will stop the calculus and an error

code will be generated in the output.

Process variable minimum value.

In case the PV value is smaller than the configured,

the PID block will stop the calculus and an error

code will be generated in the output.

Sample time.

Defines the PID block call period, in seconds,

varying from 0.001s to 1000s. This parameter is not

considered if the MeasureST is true.

When true, enables the PID block proportional

action. In case is false, the proportional action is

zero.

When true, enables the PID block derivative action.

In case is false, the derivative action is zero.

When true, enables the PID block integral action. In

case is false, the integral action is zero.

When true, the derivative action is calculated in the

process variable. It’s different than zero only when

PV is changed. In case if false, the derivative action

is calculated in the error, when depends on the SP

and PV variables.

When true, enables the manual mode. In case is

false, enables the automatic mode. The PID block

control mode affects the way the MV and the

integral action are calculated.

When true, select the direct control when the MV is

included in the answer to be included in PV. In case

is false, select the reverse control when MV is

subtracted from the answer to be included in PV.

When true, the sample time is measured. When

false, the sample time is informed by the user in the

SampleTime variable.

When true, the PID block is restarted, initializing all

variables. It can also be used to erase the integral

and derivative actions and the error codes in the

block output.

Stores the integral action which is eliminated in

error state.

Table 4-149 PID. Block Input Parameters

Loading...

Loading...