M (E3.1) 1/2023 page 101/136

18. Options

18.1 APT-COM™ 4 Multi Management Software (option)

The chamber is regularly equipped with an Ethernet interface (4) that can connect the APT-COM™ 4 Multi

Management Software. The MAC Address is indicated in the “Device info” controller menu (chap. 15.5.1.2).

The actual temperature values are given at adjustable intervals. Programming can be performed graphically

via PC. Up to 100 chambers can be cross-linked. For further information on networking please refer to the

APT-COM™ 4 operating manual.

There are three variants available:

• APT-COM™ 4 BASIC-Edition – for simple recording and documentation requirements with up to 5 net-

worked chambers.

• APT-COM™ 4 PROFESSIONAL-Edition – including scope of BASIC-Edition, additionally with conven-

ient chamber and user management, suitable for networking up to 100 chambers.

• APT-COM™ 4 GLP-Edition – including scope of PROFESSIONAL-Edition, additionally suitable for

working under GLP-compliant conditions. The measured values are documented in a tamper-proof man-

ner in accordance with the requirements of the FDA guideline 21CFR11.

18.2 Object temperature display with flexible Pt100 temperature sensor (option)

The object temperature display enables the determination of the actual temperature of the charging material

during the whole process. The object temperature is measured via a flexible Pt100 temperature sensor and

can be viewed on the controller display. You can immerse the sensor top protective tube of the flexible Pt

100 into liquid substances.

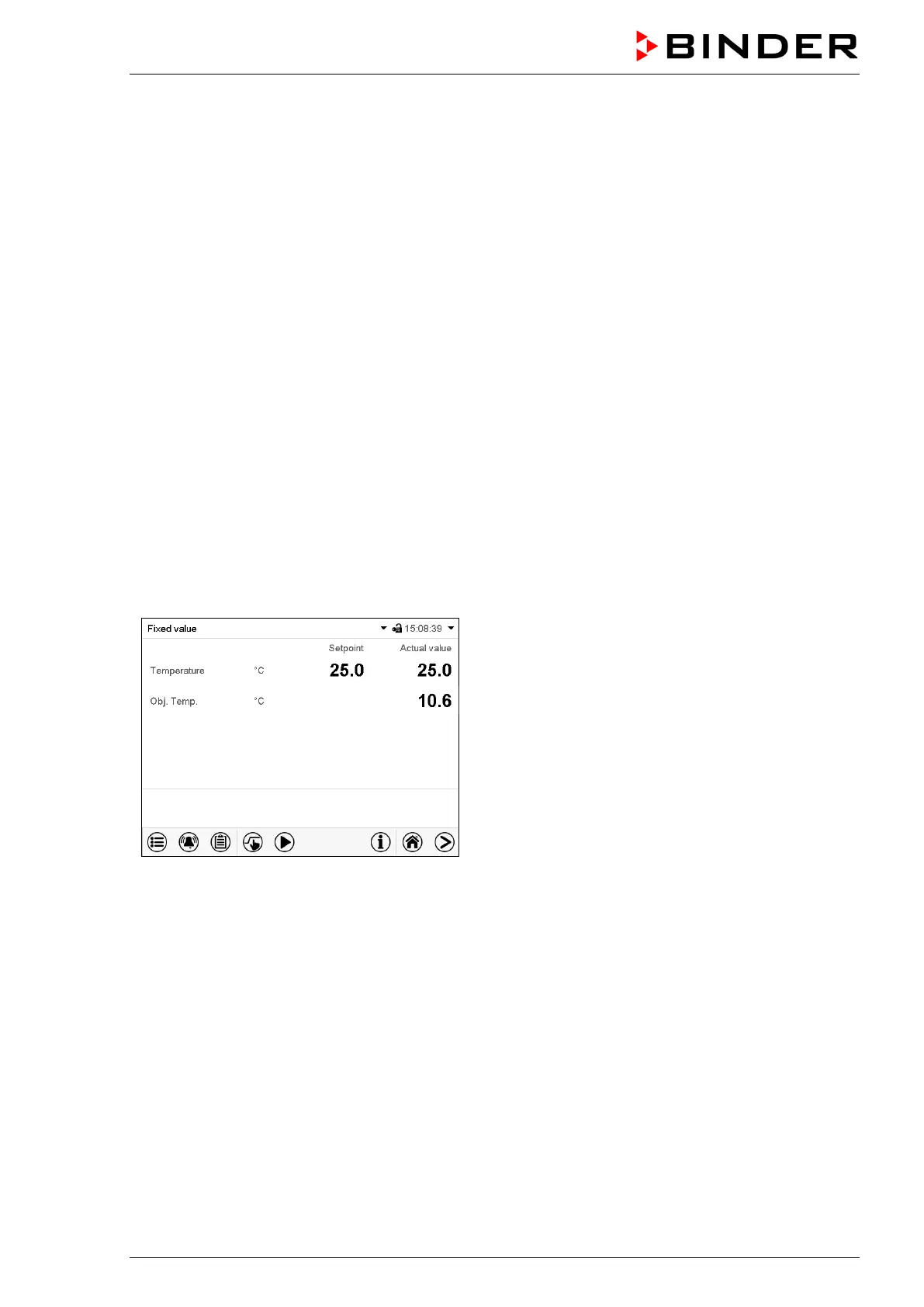

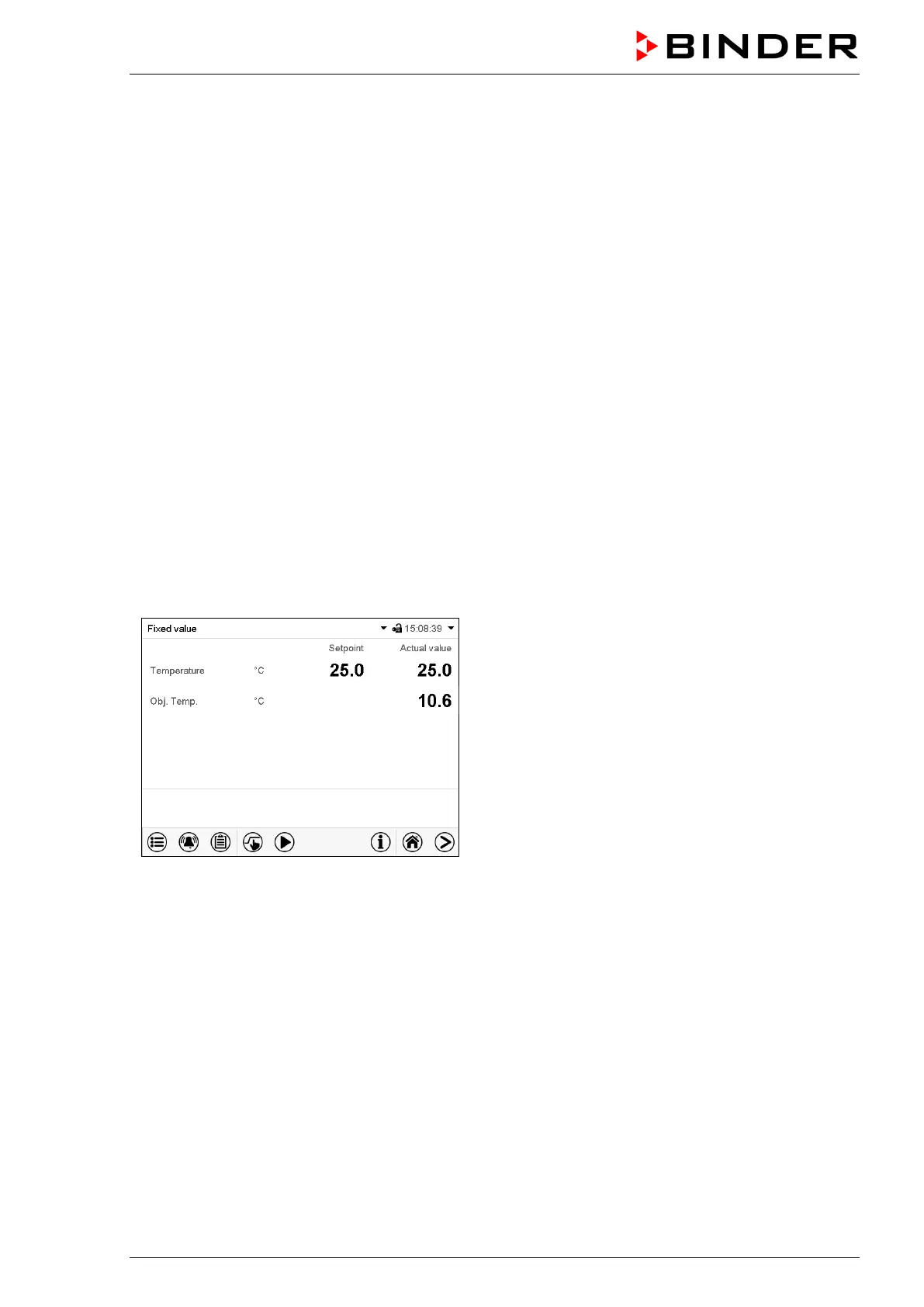

Normal display with object temperature display

(sample values)

The object temperature data are put out together with the data of the temperature controller and can be

documented by the APT-COM™ 4 Multi Management Software (option, chap. 18.1) developed by BINDER.

Technical data of the Pt100 sensor:

• Three-wire technique

• Class B (DIN EN 60751)

• Temperature range up to 320 °C / 608°F

• Stainless steel protective tube with a length of 45 mm / 1.78 in, material no. 1.4501

Loading...

Loading...