M (E3.1) 1/2023 page 103/136

The object temperature data are put out together with the data of the temperature controller and can be

documented by the APT-COM™ 4 Multi Management Software (option, chap. 18.1) developed by BINDER.

Technical data of the Pt100 sensor:

• Three-wire technique

• Class B (DIN EN 60751)

• Temperature range up to 320 °C / 608°F

• Stainless steel protective tube with a length of 45 mm / 1.78 in, material no. 1.4501

18.4 Analog output for temperature (option)

With this option the chamber is equipped with an analog output 4-20 mA for temperature. This output per-

mits transmitting data to external data registration systems or devices.

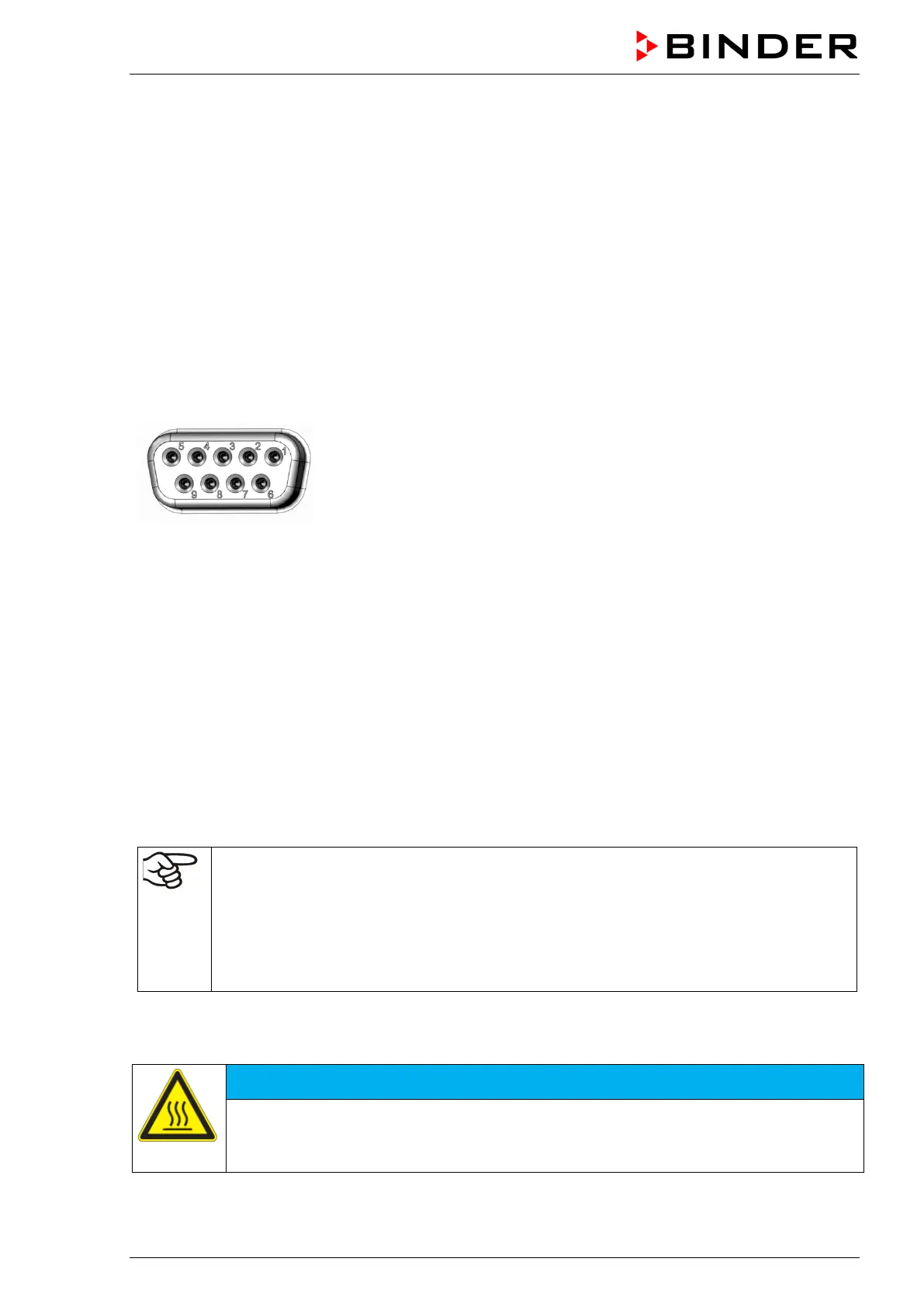

The connection is realized as a 9-poles SUB-D socket “Analog output” (7) as follows:

Analog output 4-20 mA DC

PIN 6: Temperature –

PIN 7: Temperature +

Temperature range: 0 °C up to +300 °C

Figure 14: Pin configuration of the SUB-D socket “Analog output” (7) for the analog outputs option

18.5 HEPA fresh air filter (option)

With this option, the introduced fresh air is cleaned by means of a high efficiency submicron particulate air

filter type HEPA class H 14 (acc. to DIN EN 1822:2009), 99,995 % with 0,3 µm. Replace the filter insert, if

necessary, by removing the metal cover of the filter at the left side of the chamber (Art. No. 6014-0003).

18.6 Mostly gas-tight version (option)

With this option the chamber is additionally sealed, so the loss when introducing gases is decreased. The

chamber is not completely gas-tight, so it is impossible to establish overpressure. The sealing diminishes

the release of vapors via the housing that may be set free from the charging material when heated. Carry-

ing-off via the regular evacuation duct, e.g. into a waste air installation, is likely to further reduce emissions.

The chamber is not completely gas-tight. Gases from inside the chamber can escape into

the surrounding atmosphere.

Observe the occupational exposure limit OEL for the released substance set by the national

authorities (formerly maximum permitted workplace concentration). Respect the relevant

regulations.

Any harmful gas that might escape has to be led out via good room ventilation or a suitable

exhaust system. Place the chamber, if necessary, below a gas vent.

The air flap does not close the exhaust duct completely. The delivered plug serves to avoid emerging of

vapors or loss of introduced inert gas, if any, via the exhaust duct. Due to special demands of heat re-

sistance, use the delivered plug only.

NOTICE

Danger of inflammation when using an inappropriate plug.

Damage to the chamber and ist surroundings.

Use ONLY the supplied plug to close the exhaust duct.

For drying purpose, please remove the plug in order to permit dissipation of the generated vapor, which

would lead to condensation in the inner chamber.

Loading...

Loading...