2-18 Section 2: Overview

During the default de-tangle sequence, the drive motor will shut o to release the string tension and

allow gravity to lower all pins part way towards the pindeck. After one second, the motor turns back

on to raise the pins. If a tangle is still present it will again be detected by the de-tangle switch and the

motor will shut o for another second to lower the pins. After 5 attempts to de-tangle the strings, the

motor shuts o to lower the pins completely to the pindeck. After 2 seconds the motor turns back on to

lift the pins to begin another 5 attempt sequence. The pattern will repeat until the tangle is corrected

or the pattern has repeated 6 times (30 attempts). After 30 failed attempts to correct the problem, the

motor will shut o to allow the pins to lower to the pindeck, the trouble light will ash, and Controller

will display a “Tangle-01” error code. At this point a service person must turn o the machine and

manually correct the problem.

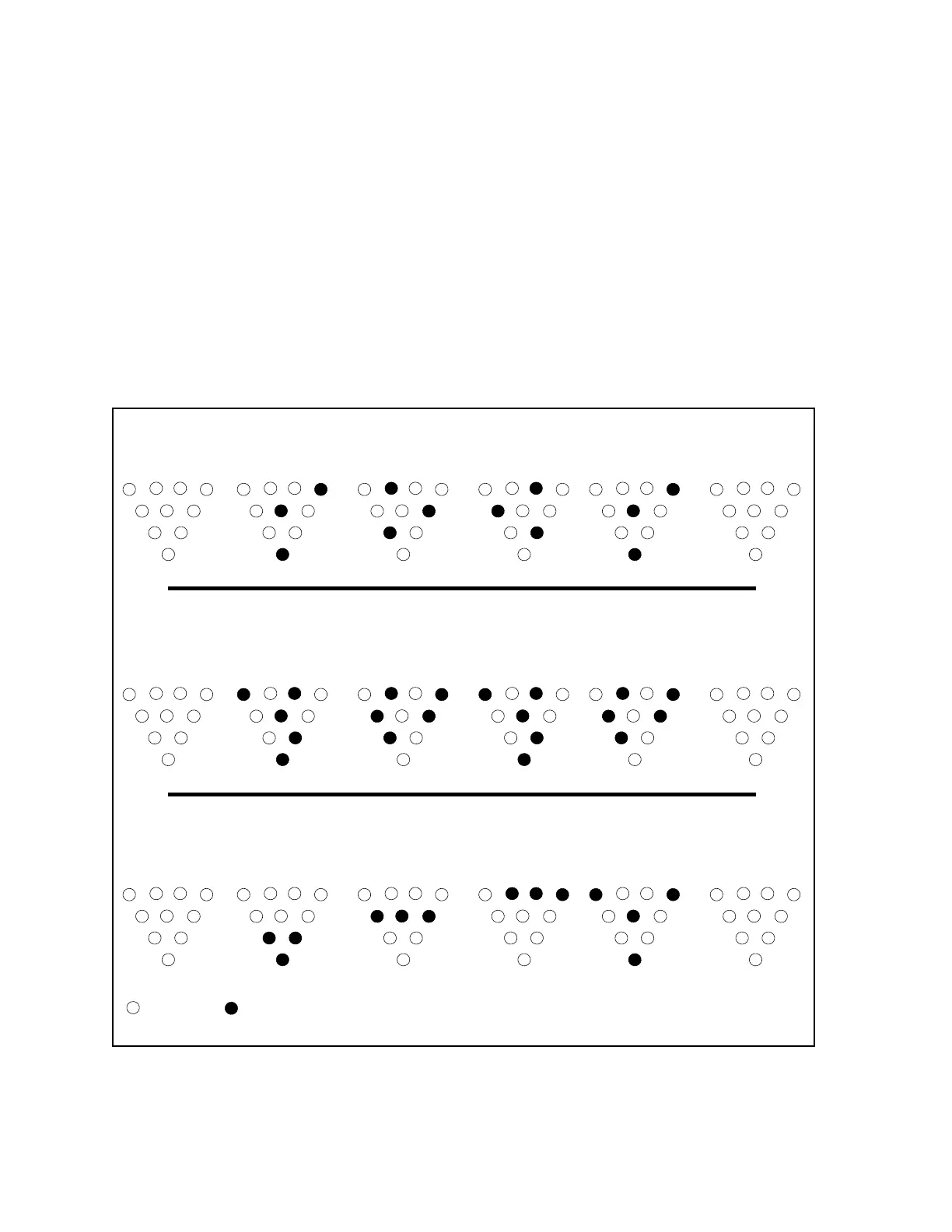

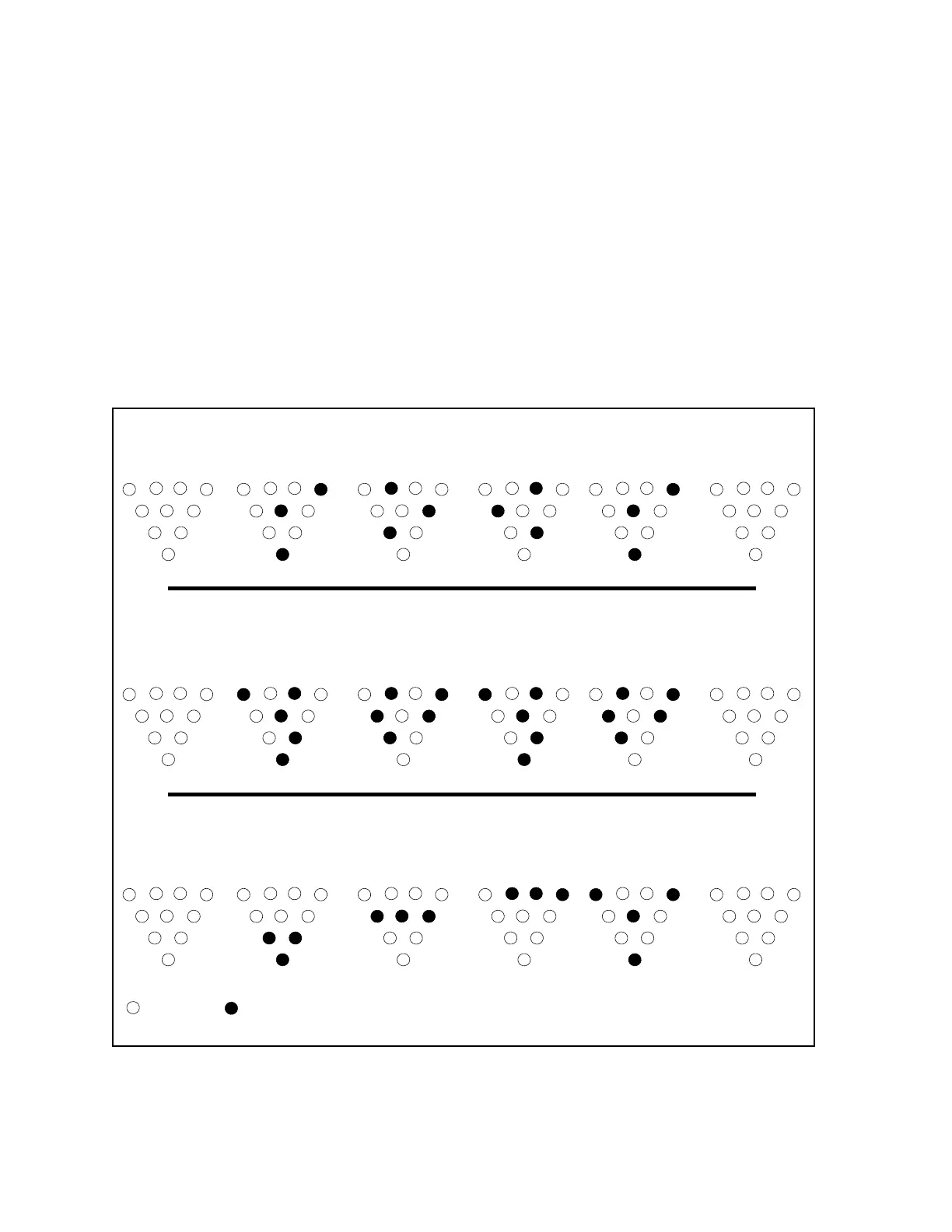

To further increase the chances that the de-tangle procedure will be successful, alternative shake

patterns can be selected on the Options screen of the 360 Controller. Unlike the default sequence where

all pins are lowered toward the pindeck, these options use the brakes within the PMI’s to produce a

repeating pattern during which only specic pins are allowed to lower. Refer to Figure2-18.

(B)

Sequence2nd

(C)

Sequence3rd

(A)

1st Sequence

(D)

Sequence4th

(B)

Sequence2nd

(C)

Sequence3rd

(A)

1st Sequence

(D)

Sequence4th

(B)

Sequence2nd

(C)

Sequence3rd

(A)

1st Sequence

(D)

Sequence4th

= Pins Lowered

= Pins Not Lowered

Each Sequence Repeats Five Times

(E)

Sequence5rd

(F)

Sequence6th

(E)

Sequence5rd

(F)

Sequence6th

(E)

Sequence5rd

(F)

Sequence6th

HOLD 3 SEQUENCE (SES):

ODD-EVEN SEQUENCE:

WAVE SEQUENCE:

Figure2-18.PinLoweringPatternDuringtheDe-TangleSequence

(1) 1ST SEQUENCE (2) 2ND SEQUENCE (3) 3RD SEQUENCE

(4) 4TH SEQUENCE (5) PINS LOWERED (6) PINS NOT LOWERED

(7) EACH SEQUENCE REPEATS

FIVE TIMES

Loading...

Loading...