Section 5: Maintenance & Service 5-1

Section 5 - Maintenance & Service

WARNING! When performing any maintenance or machine service, make sure

the main power is turned o and the power plug has been disconnected.

SERVICE PROCEDURES

Repairing Worn String

1. Unwind a length of string from the String Spool similar to the length of string that needs to be

replaced.

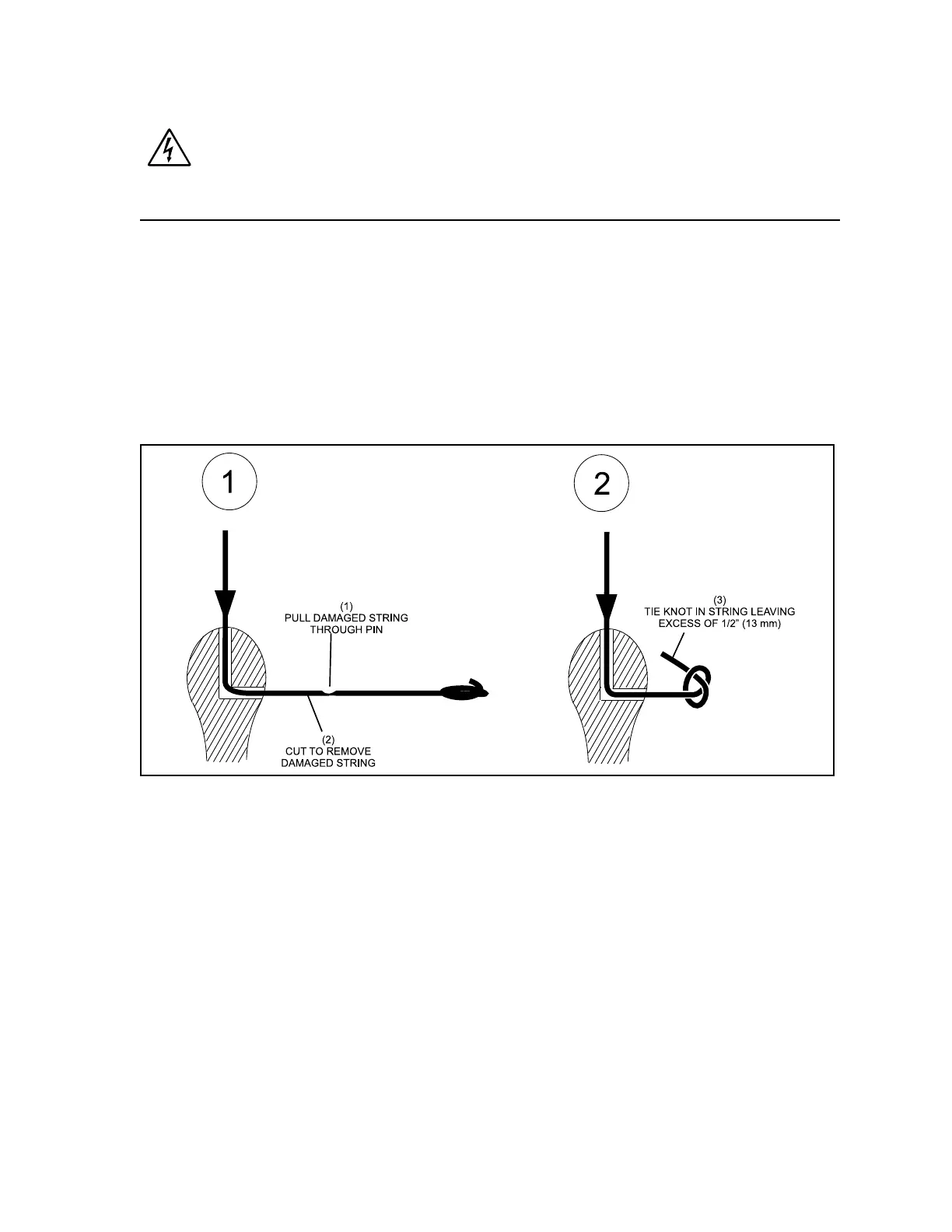

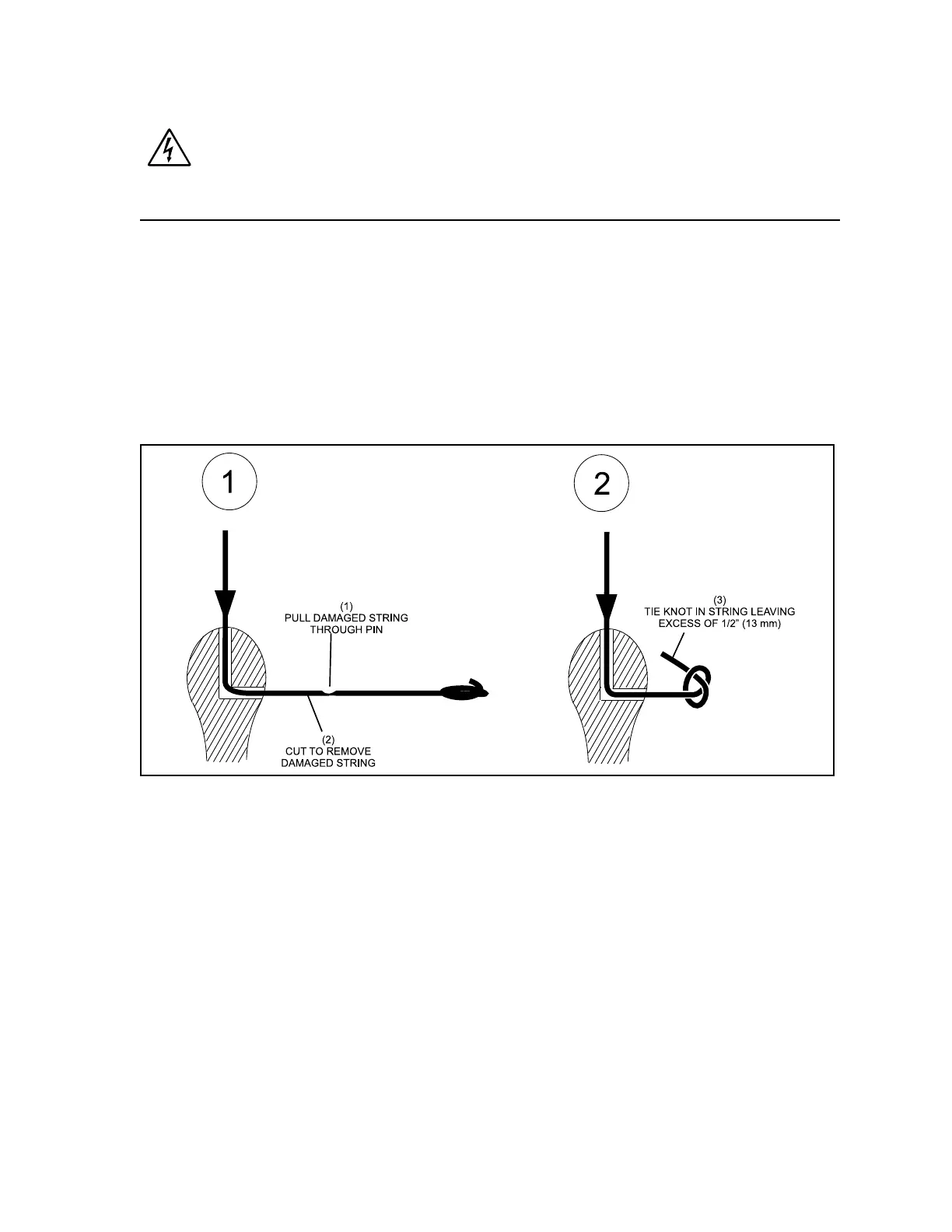

2. From under the setting platform, pull the string through the machine towards the pin. Continue

pulling the string through the head of the pin so that the worn portion of the string is all the way

through the pin. Refer toFigure5-1.

Figure5-1.ThreadStringThroughPin

(1) PULL DAMAGED STRING (2) CUT TO REMOVE DAMAGED (3) TIE KNOT IN STRING

THROUGH PIN STRING LEAVING EXCESS OF 1/2” (13 mm)

3. Cut the string at the String Spool side of the damage. Discard the damaged string.

4. Tie a knot in the end of the “good” string. Leave approximately 1/2” (13 mm) of string

extending beyond the end of the knot. Refer toFigure5-1.

5. Pull the string back through the pin until the knot bottoms out in the pin. Refer to Figure5-1.

6. Perform the String Tension Adjustment for any pin where the string has been repaired.

Loading...

Loading...