Section4:Adjustments 4-9

2. Observe and Adjust

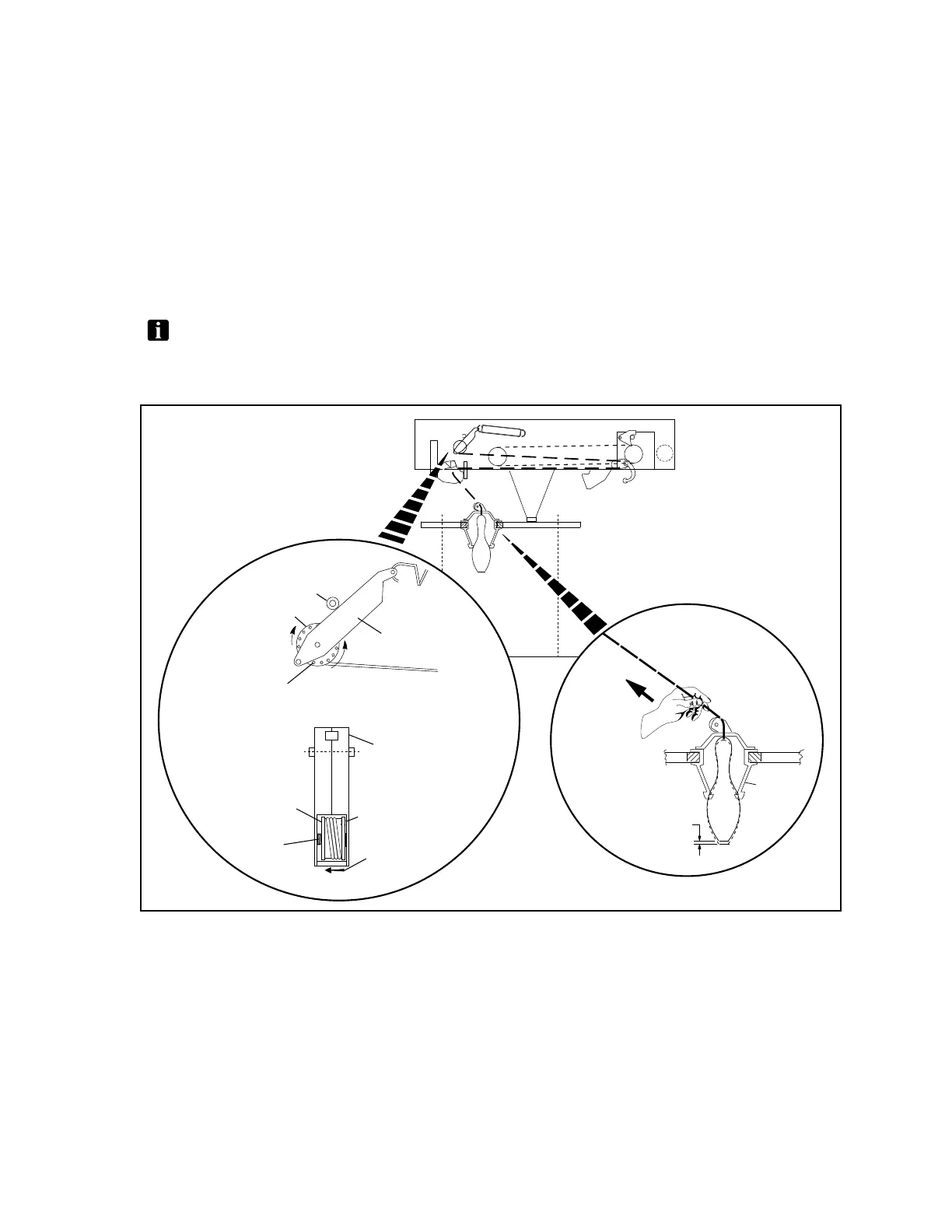

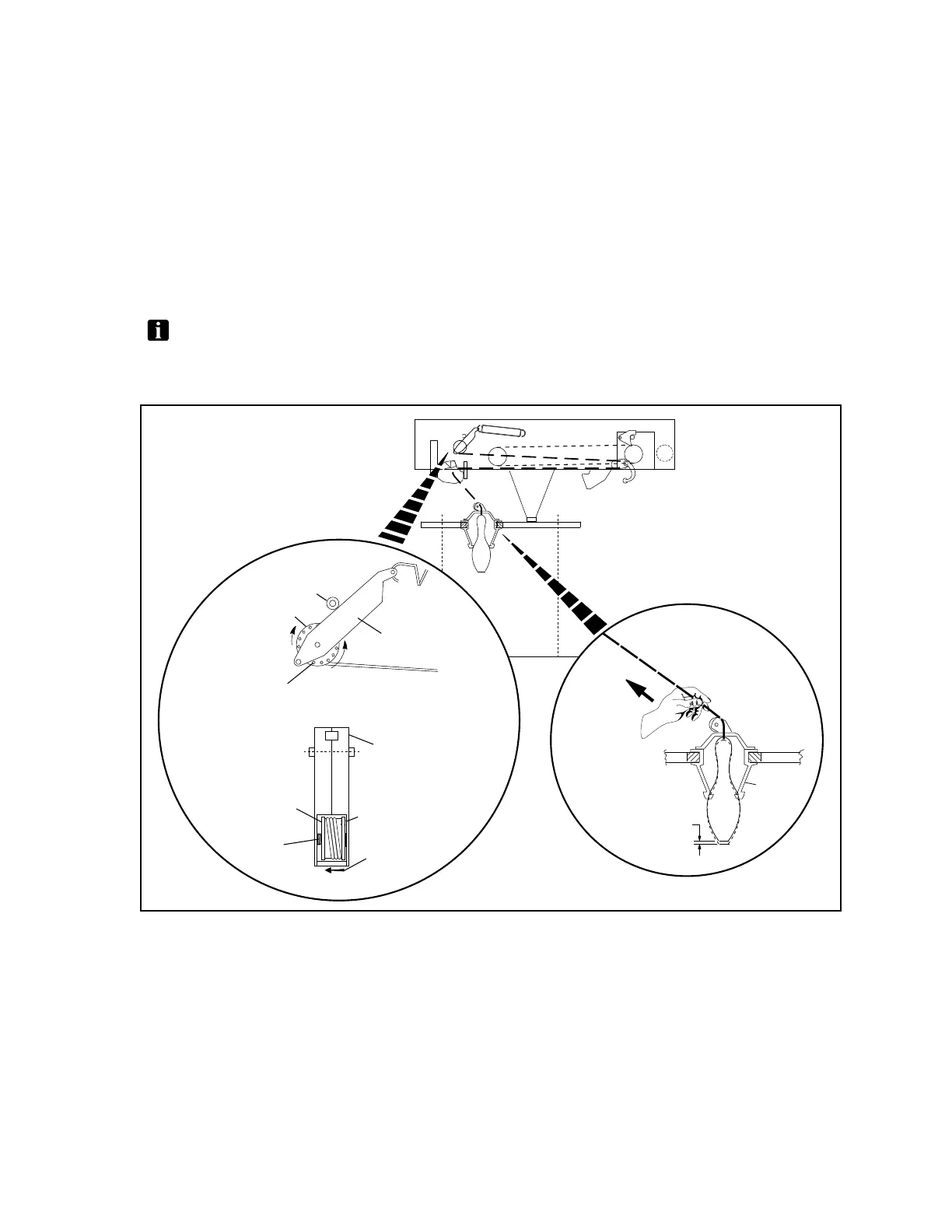

a. Check the movement of a raised pin in the pin centering cone by pulling on its string. The

travel distance of the pin should be 1-3 mm + 2 mm. Refer toFigure4-9.

b. If the tension adjustment is required for any of the pins. Refer to Figure 4-9;

Slide the string spool away from locking pins to release the spool reel.

Rotate the string reel as needed to obtain the 1-3 mm + 2 mm travel distance.

When the proper gap has been obtained, move the string reel to the right rotating it as

required to align its holes with locking pins.

NOTE:Rotatingthespooltowardsthebackofthemachinewillreducethetensionandgap.

Rotatingthespooltowardthefrontofthemachinewillincreasethetensionandgap.Referto

Figure 4-9.

(1)

CENTERING

CONE

(2)

1-3 mm

± 2 mm

(3)

LIMITER

BAR

(12)

SPOOL

LOCKING

PIN

(7)

STRING

TENSION

ADJUSTMENT

HOLES

(4)

TENSION

LEVER

(5)

STRING

SPOOL

(5)

STRING

SPOOL

(4)

TENSION

LEVER

(6)

SIDE VIEW

(8)

FRONT VIEW

(11)

SPOOL

LOCKING

SPRING

(9)

(10)

(13)

SLIDE SPOOL

TOWARD SPRING

TO UNLOCK

Figure4-9.StringTensionAdjustments

(1) CENTERING CONE (2) 1-2 MM ± 2 MM (3) LIMITER BAR

(4) TENSION LEVER (5) STRING SPOOL (6) SIDE VIEW

(7) STRING TENSION (8) FRONT VIEW (9) ROTATE SPOOL TO TIGHTEN

ADJUSTMENT HOLES

(10) ROTATE SPOOL TO LOOSEN (11) SPOOL LOCKING SPRING (12) SPOOL LOCKING PIN

(13) SLIDE SPOOL TOWARD SPRING

TO UNLOCK

Loading...

Loading...